ਨਵੰ. . 06, 2024 14:52 Back to list

How to Effectively Replace Seals in Hydraulic Cylinders for Optimal Performance

Replacing Seals in Hydraulic Cylinders A Comprehensive Guide

Hydraulic cylinders are essential components in various industrial applications, providing the force necessary to lift, push, or pull heavy objects with precision and efficiency. However, like any mechanical system, hydraulic cylinders are subject to wear and tear over time, particularly in their seals. Replacing seals in hydraulic cylinders is a critical maintenance task that ensures the reliable operation of the machinery. In this article, we will explore the importance of seals, the signs of seal failure, the steps involved in replacing seals, and tips for ensuring long-lasting performance.

The Importance of Seals

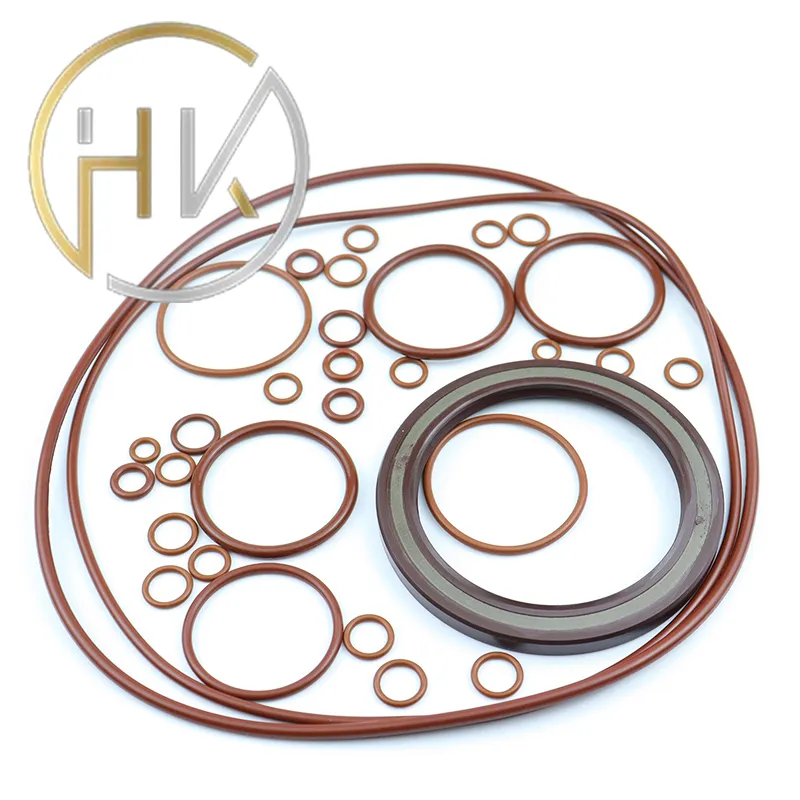

Seals in hydraulic cylinders perform a vital function—preventing hydraulic fluid from leaking out and contaminants from entering the system. These seals are responsible for maintaining the pressure needed for the hydraulic functions to operate effectively. Without properly functioning seals, hydraulic systems can experience reduced efficiency, increased maintenance costs, and potential damage to components due to contamination and fluid loss.

Signs of Seal Failure

Recognizing the signs of seal failure early on can save time, money, and prevent further damage. Common indicators of seal failure include

1. Fluid Leaks The most obvious sign is hydraulic fluid seeping from the cylinder, which can be seen pooling around the base. 2. Decreased Performance If the hydraulic cylinder is struggling to maintain pressure or carry out its functions, it may be due to compromised seals.

3. Unusual Noises Grinding or hissing sounds can indicate that seals are worn and not functioning correctly.

4. Increased Cycle Times When seals fail, hydraulic systems may take longer to complete their cycles due to pressure loss.

If you notice any of these signs, it is crucial to inspect the hydraulic cylinder and consider replacing the seals promptly.

Steps to Replace Seals in Hydraulic Cylinders

Replacing seals in hydraulic cylinders may seem daunting, but with the right tools and careful attention, it can be accomplished effectively. Here’s a step-by-step guide

1. Gather Necessary Tools and Materials You'll need wrenches, screwdrivers, pliers, a seal kit, and replacement hydraulic fluid. Make sure to have clean rags and a cleaning solution on hand to keep the working area clean.

2. Depressurize the System Before beginning any work, ensure the hydraulic system is depressurized to prevent accidents. Follow the manufacturer’s specifications to safely release pressure.

replacing seals hydraulic cylinder

3. Disassemble the Cylinder Remove the cylinder from the machinery, and then carefully take apart the various components, including the cylinder rod and end caps. Keep all parts organized for easier reassembly.

4. Inspect Components Check the internal surface of the cylinder for wear or damage. If the cylinder itself is damaged, it may need resurfacing or replacement.

5. Replace the Seals Remove the old seals and clean the grooves thoroughly. Install the new seals, ensuring they are correctly seated and compatible with the fluid used in the system.

6. Reassemble the Cylinder Carefully reassemble the hydraulic cylinder in the reverse order of disassembly. Ensure all components are tightened to the manufacturer’s specifications.

7. Refill with Hydraulic Fluid Once the cylinder is reassembled, refill it with the appropriate type of hydraulic fluid.

8. Test the System Reconnect the hydraulic cylinder to the machinery, and gradually restore pressure while observing for leaks or performance issues.

Tips for Long-Lasting Performance

To ensure the longevity of seals in hydraulic cylinders, consider the following tips

- Regular Maintenance Schedule regular inspections and maintenance to catch issues early. Check the seals for signs of wear and replace them as needed.

- Choose Quality Seals Invest in high-quality seals that are designed for your specific application and hydraulic fluid. Low-quality seals can lead to premature failure.

- Maintain Cleanliness Contaminants can accelerate seal wear. Keep the hydraulic system clean and free of dirt and debris.

- Monitor Operating Conditions Ensure that the hydraulic cylinder operates within the specifications recommended by the manufacturer, including pressure and temperature limits.

In conclusion, replacing seals in hydraulic cylinders is a critical maintenance task that can enhance the reliability and efficiency of hydraulic systems. By understanding the importance of seals, recognizing the signs of failure, and following the proper steps to replace them, you can ensure that your hydraulic machinery continues to function effectively for years to come.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories