ਫਰ. . 01, 2025 03:05 Back to list

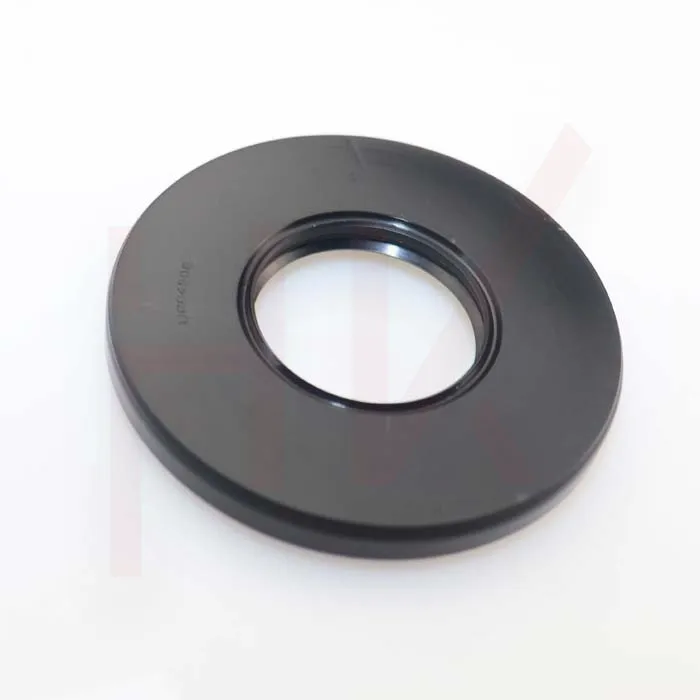

shaft oil seal

Authority in the field of oil seals is underscored by continuous research and development. Leading manufacturers invest significantly in innovation, evidenced by the development of seals that integrate sensor technologies to monitor wear and predict maintenance needs. This smart technology integration aligns with the broader industry shift towards predictive maintenance, empowering businesses to preemptively address potential seal failures before they culminate in costly repairs or unplanned downtime. Trust, a crucial indicator of the reliability of an oil seal, is built upon rigorous testing and quality assurance processes. Reputable manufacturers adhere to industry standards and employ state-of-the-art testing methodologies to ensure their seals can withstand the rigors of industrial application. This commitment to quality not only fosters trust but also solidifies the manufacturer's reputation as a leader in the industry. Real-world experiences bear testament to the impact of selecting the appropriate oil seal. For instance, a leading automobile manufacturer reported a significant reduction in warranty claims related to oil leakage issues by switching to a high-performance elastomer seal. This transition not only bolstered customer satisfaction but also enhanced the brand's credibility as a manufacturer of reliable vehicles. In conclusion, oil seals for rotating shafts may appear as a small component in the vast machinery landscape, but their role is pivotal. The convergence of experience, expertise, authority, and trustworthiness in the development and application of oil seals ensures they continue to empower industries by enhancing machinery efficiency, reliability, and longevity. Embracing the advancements in oil seal technology offers industries the leverage to optimize operations, mitigate risks, and fortify their production systems against the relentless demands of modern industrial ecosystems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories