ਅਕਤੂਃ . 13, 2024 16:32 Back to list

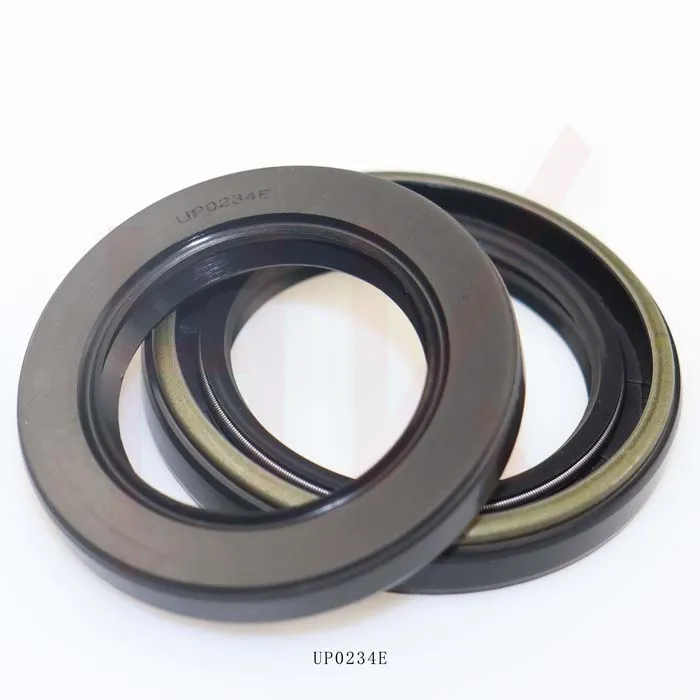

high pressure hydraulic shaft seals

High Pressure Hydraulic Shaft Seals An Overview

In various industrial applications, hydraulic systems play a crucial role in the efficient operation of machinery and equipment. Among the essential components in these systems are high pressure hydraulic shaft seals, which are designed to prevent fluid leakage and maintain the integrity of hydraulic circuits. This article explores the significance, types, materials, and applications of high pressure hydraulic shaft seals.

Importance of High Pressure Hydraulic Shaft Seals

High pressure hydraulic shaft seals serve a pivotal function in hydraulic systems by containing hydraulic fluid within cylinders and preventing external contaminants from entering the system. Effective sealing is critical, as any leakage can lead to significant loss of efficiency, increased operational costs, and potential damage to equipment. Moreover, well-designed seals contribute to the longevity of machinery by minimizing wear and tear on components.

Types of High Pressure Hydraulic Shaft Seals

There are several types of hydraulic shaft seals, each suited for specific applications and operating conditions. The most common types include

1. Lip Seals These seals feature a flexible lip that creates a tight seal against the shaft. They are commonly used in medium-pressure applications and are known for their ease of installation and cost-effectiveness.

2. O-Ring Seals Often employed in static and dynamic sealing applications, O-rings are circular seals that provide an excellent seal for low and moderate pressure situations. However, for high-pressure applications, multiple O-rings or backup rings may be used to enhance sealing performance.

3. PTFE Seals Polytetrafluoroethylene (PTFE) seals are highly resistant to chemicals and extreme temperatures. They are ideal for high-pressure environments and are used in applications where fluid compatibility is a concern.

4. Composite Seals These seals combine different materials to leverage their strengths. For instance, a rubber core surrounded by a PTFE outer layer provides excellent sealing capabilities in high-pressure situations while maintaining flexibility.

high pressure hydraulic shaft seals

Materials Used in High Pressure Hydraulic Shaft Seals

The choice of material for hydraulic shaft seals is paramount in determining their performance and reliability. Typical materials include

- Nitrile Rubber (NBR) Known for its good oil resistance, NBR is widely used in hydraulic seals. However, it has limitations in extreme temperatures.

- Fluorocarbon (FKM) This material is excellent for high-temperature and aggressive fluid applications, making it suitable for advanced hydraulic systems.

- Polyurethane (PU) Offering high wear resistance, PU seals can endure high pressure and provide excellent sealing in demanding environments.

- PTFE As mentioned earlier, PTFE seals are ideal for high-pressure situations and are resistant to a wide range of chemicals.

Applications of High Pressure Hydraulic Shaft Seals

High pressure hydraulic shaft seals are utilized in a myriad of industries, including aerospace, automotive, construction, and manufacturing. They are commonly found in hydraulic cylinders, pumps, motors, and other equipment where hydraulic fluid containment is essential.

In conclusion, high pressure hydraulic shaft seals are vital components in hydraulic systems, ensuring efficiency, safety, and longevity of machinery. By choosing the right type and material, industries can enhance the performance of their hydraulic applications and minimize the risks associated with fluid leakage and contamination. As technology advances, the development of new materials and designs will continue to improve the reliability and efficiency of hydraulic sealing solutions.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories