ਨਵੰ. . 01, 2024 13:01 Back to list

Essential Hydraulic Cylinder Seal Kit for Chief Equipment Maintenance and Repair

Understanding Chief Hydraulic Cylinder Seal Kits

In the world of hydraulic systems, the seamless operation and longevity of machinery heavily depend on the integrity of the hydraulic cylinder seal kits. Among the myriad options available, Chief hydraulic cylinder seal kits stand out for their reliability and performance. These kits are vital components used in hydraulic cylinders, which are central to various industrial applications, including construction equipment, agricultural machinery, and manufacturing systems.

Understanding Chief Hydraulic Cylinder Seal Kits

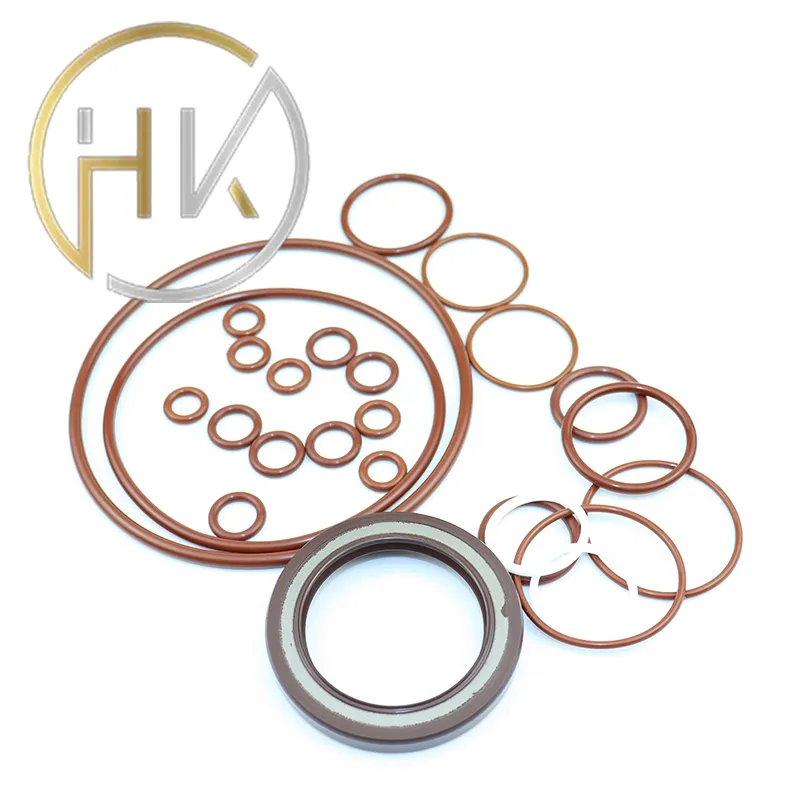

Chief hydraulic cylinder seal kits typically include a range of seals made from high-quality materials such as nitrile rubber, polyurethane, or fluorocarbon. These materials are chosen for their excellent resistance to wear, temperature fluctuations, and chemical exposure, ensuring that they can withstand the demanding environments in which hydraulic systems operate. By selecting a Chief seal kit, operators can expect enhanced performance, reduced maintenance downtime, and extended service life for their equipment.

chief hydraulic cylinder seal kit

One of the key benefits of using Chief hydraulic cylinder seal kits is the availability of kits tailored for specific applications. Whether it’s for a compact excavator, a forklift, or a heavy-duty truck, Chief offers a comprehensive range of options to meet diverse operational needs. These custom kits often include various sizes and types of seals, such as O-rings, rods, and piston seals, to provide a complete solution for hydraulic systems.

Installation of Chief hydraulic cylinder seal kits is crucial for maintaining optimal performance. Proper installation techniques can prevent leaks, ensure efficient operation, and reduce the risk of costly repairs. It is recommended that technicians familiarize themselves with the installation guidelines and use the appropriate tools to achieve a perfect fit. Additionally, regular inspection and maintenance of hydraulic systems can further prolong the lifespan of the seals and overall equipment.

Another noteworthy aspect is the training and support available for users of Chief hydraulic cylinder seal kits. Companies that stock these kits often provide resources, manuals, and expert advice, helping customers understand the best practices for installation and maintenance. This level of support is invaluable in ensuring that operators can confidently maintain their hydraulic systems and keep them running smoothly.

In conclusion, Chief hydraulic cylinder seal kits are essential components that significantly impact the efficiency and reliability of hydraulic machinery. With their high-quality materials, tailored options, and the backing of expert support, these kits are designed to meet the rigorous demands of various industries. By investing in Chief hydraulic cylinder seal kits, operators can expect not only a reduction in leakage and wear but also improved productivity and operational efficiency in their hydraulic systems. Whether you are in construction, manufacturing, or any other sector relying on hydraulic machinery, ensuring the integrity of your hydraulic seals is key to sustaining performance and reducing operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories