ਫਰ. . 05, 2025 03:08 Back to list

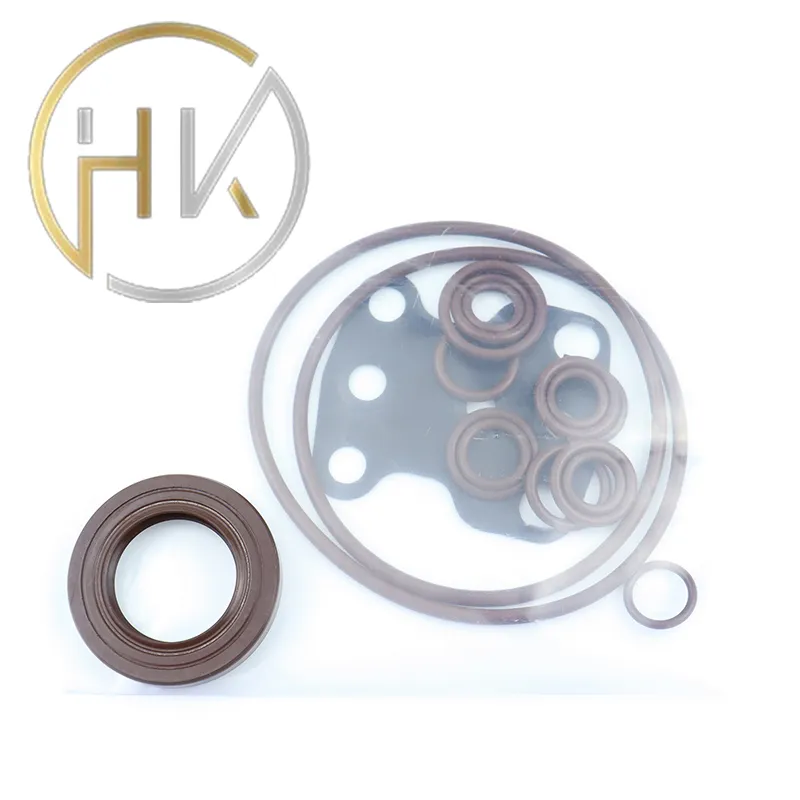

dkb seal

Field experience has long underscored the cost-saving benefits of investing in high-quality bearing dust seals. A comprehensive understanding of how these seals can mitigate operational disruptions enhances an industry professional's capabilities in preventative maintenance. For example, in a case study from the mining sector, implementing more robust sealing solutions reduced unscheduled downtime by 25%, showcasing the seals' capacity to improve productivity while cutting maintenance costs. In providing recommendations, always consider seal compatibility with the bearing type and lubricant involved. Understanding the interactions between these components ensures a longer service life and saves on replacement investments, aligning with industry best practices. When possible, consult with manufacturers or seasoned experts to ensure the compatibility and efficacy of these seals within specific machinery setups. Acquiring authoritative knowledge in bearing dust seals fosters trustworthiness in professional circles. Engineers and technical teams that prioritize the right sealing solutions build a reputation for reliability and excellence. Furthermore, knowledge sharing through seminars, white papers, and professional forums can enhance collective understanding and innovation in sealing technology. Ultimately, the integration of top-tier bearing dust seals is not just about protection; it's about precision engineering that champions equipment longevity, enhances operational efficiency, and offers substantial cost benefits over the equipment's lifecycle. Those equipped with the skills and knowledge to effectively implement and manage these components will invariably advance in sectors where technical excellence is paramount.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories