Oct . 02, 2024 06:19 Back to list

Understanding the Function and Importance of Wiper Rings in Mechanical Seals

Understanding Wiper Rings Essential Components in Machinery

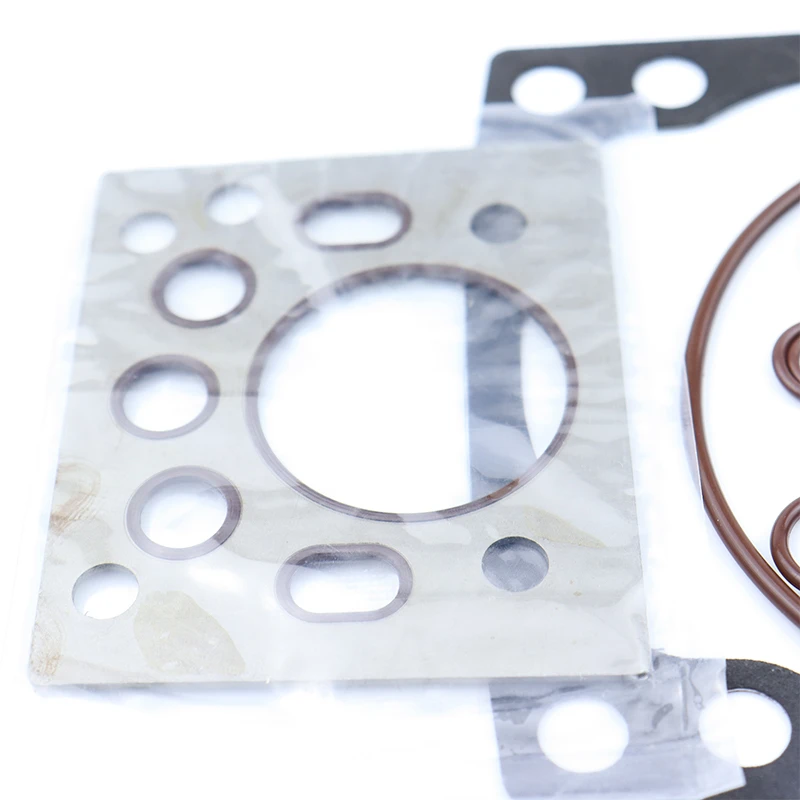

Wiper rings, often overlooked in the grand scheme of machinery, play a critical role in ensuring the efficiency and longevity of various mechanical systems. These small yet vital components are integral to hydraulic and pneumatic cylinder operations, providing sealing solutions that enhance performance and prevent contamination.

Wiper rings are specifically designed to remove debris, dirt, and other unwanted particles from the surface of a piston as it moves within a cylinder. This is crucial because even the slightest amount of contamination can lead to significant wear and tear on the seals and internal components, ultimately resulting in failures that could disrupt operations and incur high repair costs. By preventing contaminants from entering the cylinder, wiper rings help maintain the integrity of hydraulic systems, ensuring they function smoothly and reliably.

The construction of wiper rings can vary significantly depending on the application and the specific requirements of the machinery in which they are used. Generally made from durable materials such as polyurethane, rubber, or PTFE (polytetrafluoroethylene), these rings are designed to withstand harsh operating conditions, including extreme temperatures and pressures. The choice of material is crucial, as it determines the wiper ring’s resistance to wear, flexibility, and overall performance.

wiper ring

One of the most important aspects to consider when selecting a wiper ring is its size and design. These factors directly affect how well the wiper ring will perform in its intended application. For example, a wiper ring that is too loose may fail to effectively remove debris, while one that is too tight may cause excessive friction and lead to premature wear. Therefore, precision engineering is essential in the manufacturing of wiper rings to ensure they fit perfectly within their respective systems.

There are also different types of wiper rings tailored for specific applications. For instance, some designs feature a lip or edge that enhances their ability to scrape contaminants away from the piston rod, while others are constructed to minimize drag and friction. These design variations allow engineers to select the best wiper ring for any given application, optimizing performance and enhancing the lifespan of the machinery.

Maintenance is another critical aspect related to wiper rings. Regular inspections can help identify wear or damage, allowing for timely replacements that prevent larger issues down the line. Neglecting this aspect can lead to decreased machinery performance, increased operational costs, and even complete system failures.

In summary, wiper rings are far more than just simple components; they are essential to the reliable operation of hydraulic and pneumatic systems. By effectively removing contaminants and protecting vital machinery parts, these small yet significant rings play a pivotal role in maintaining efficiency and prolonging the lifespan of various applications. Investing in high-quality wiper rings and ensuring proper maintenance can significantly enhance the overall performance and reliability of machinery, ultimately benefiting operations in numerous industries. Understanding their importance can lead to more educated decisions in machinery design and maintenance practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories