Jan . 14, 2025 10:23 Back to list

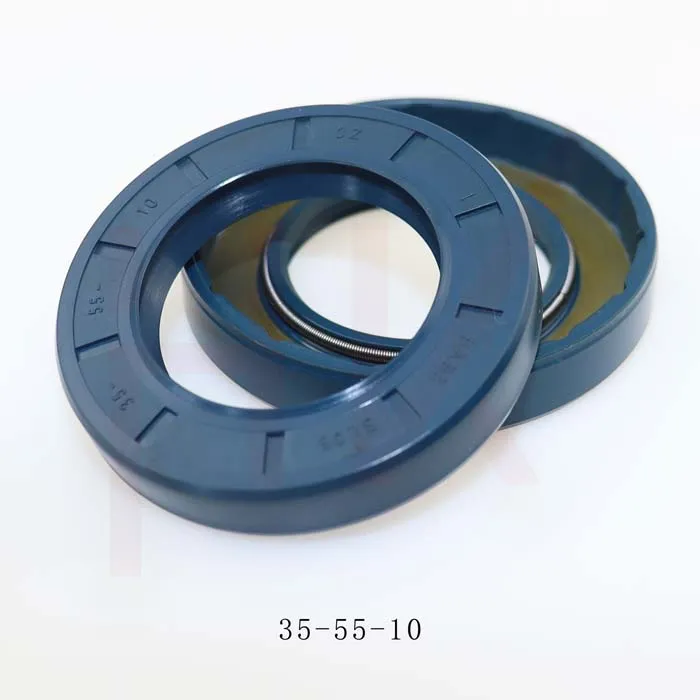

Standard Wheel Hub Oil Seal For Agricultural Machinery

Moreover, the proper selection and installation of these seals are paramount to realizing their benefits. Expertise in the precise requirements of pressure, temperature, and environment is necessary for selecting the right seal. Collaboration with manufacturers, which offer insightful analyses and recommendations based on real-world applications, is a pragmatic approach to achieving optimal results. The authority of high pressure oil seals in industrial applications is backed by continuous innovations and rigorous testing. Leading manufacturers conduct extensive R&D to develop seals that not only meet but exceed industry standards. By incorporating cutting-edge technology and materials science, these seals are more robust than ever, offering unrivaled reliability even in the harshest environments. Trustworthiness in these products is fortified through compliance with international standards and certifications, such as ISO and ASTM, ensuring that high pressure oil seals are a reliable choice for critical applications. Companies can thus confidently incorporate these seals into their systems, knowing they are backed by scientific expertise and regulatory assurance. In conclusion, high pressure oil seals are vital to maintaining operational integrity in industrial systems. With their advanced designs and materials, they offer unmatched performance and reliability. When selected and utilized correctly, these seals not only safeguard machinery but also enhance overall productivity and safety, making them a keystone component in any high-performance industrial application.

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

Products categories