Dec . 10, 2024 05:26 Back to list

seals and wipers

Seals and Wipers The Unsung Heroes of Mechanical Performance

In the intricate world of machinery and automotive design, some components often go unnoticed despite their crucial roles in ensuring smooth operations. Among these unsung heroes are seals and wipers. Although seemingly simple in design, these elements serve vital functions that enhance the durability, efficiency, and safety of various mechanical systems.

Understanding Seals

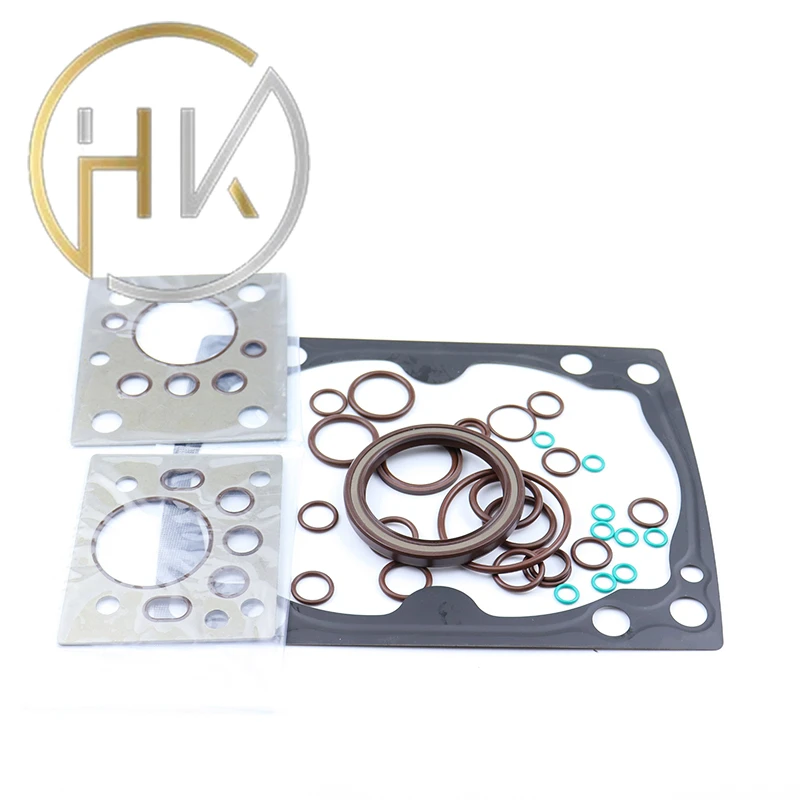

Seals are engineered components that prevent the escape of fluids or gases from a given space, maintaining pressure and protecting against contamination. They come in many forms—rubber O-rings, mechanical seals, lip seals, and many more—each tailored for specific applications. In the automotive industry, seals are essential in engine assemblies, transmissions, and differential housings. They prevent oil and coolant from leaking out, which not only maintains the desired pressure within the system but also protects against dirt and debris that could lead to premature wear or catastrophic failure.

One of the most critical functions of seals is their ability to withstand various pressures and temperatures. For example, the engine oil seal must endure high temperatures and pressures without losing integrity. The material used in seals, therefore, plays a significant role in their performance. Modern seals use advanced materials such as fluorocarbon and polyurethane, which can withstand harsh conditions while providing excellent sealing properties.

The Role of Wipers

Wipers, on the other hand, primarily serve to protect surfaces from debris and contaminants. In the context of machinery, wipers are often found in hydraulic systems, where they prevent dirt and contaminants from entering the hydraulic cylinder. This is critical in maintaining the efficiency and longevity of hydraulic systems, as contamination can lead to significant wear and failure.

seals and wipers

In automotive applications, wipers are perhaps best known for their role in windshield wipers, which enhance visibility during adverse weather conditions. However, their importance extends beyond just clearing water and snow; they also protect the glass from abrasives and dirt that could scratch or damage the surface. In industrial machinery, wipers act similarly, ensuring that moving parts remain clear of obstructions that could hinder performance.

The Importance of Maintenance

Despite their importance, seals and wipers are often overlooked during maintenance checks. Regular inspections can help identify wear and tear, allowing for timely replacements that can prevent bigger issues down the line. For instance, a degraded seal can lead to oil leaks, which not only pose a risk to the engine's health but can also result in environmental contamination. Similarly, worn out wipers may allow dirt and debris to enter sensitive machinery, leading to costly repairs.

In industrial settings, ensuring that seals and wipers are regularly replaced can result in significant cost savings. Machinery downtime due to failure can be incredibly expensive. By implementing a proactive maintenance strategy that includes careful monitoring of these components, businesses can avoid the unexpected costs associated with mechanical breakdowns.

The Future of Seals and Wipers

As technology advances, the future of seals and wipers looks promising. Innovations in materials science are leading to the development of more resilient and efficient sealing solutions. Smart seals that can detect wear and provide alerts when maintenance is due are on the horizon, potentially transforming how industries approach machinery maintenance.

In summary, while seals and wipers may not be the most glamorous components in machinery and automotive design, their roles are undeniably significant. They protect valuable assets from wear, maintain efficiency, and enhance the safety of operations across various applications. As industries continue to evolve, understanding and investing in these components will be key to achieving optimal performance and reliability. So, the next time you check your car or industrial machinery, take a moment to appreciate the humble seals and wipers—small yet mighty components that keep everything running smoothly.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories