Nov . 14, 2024 18:37 Back to list

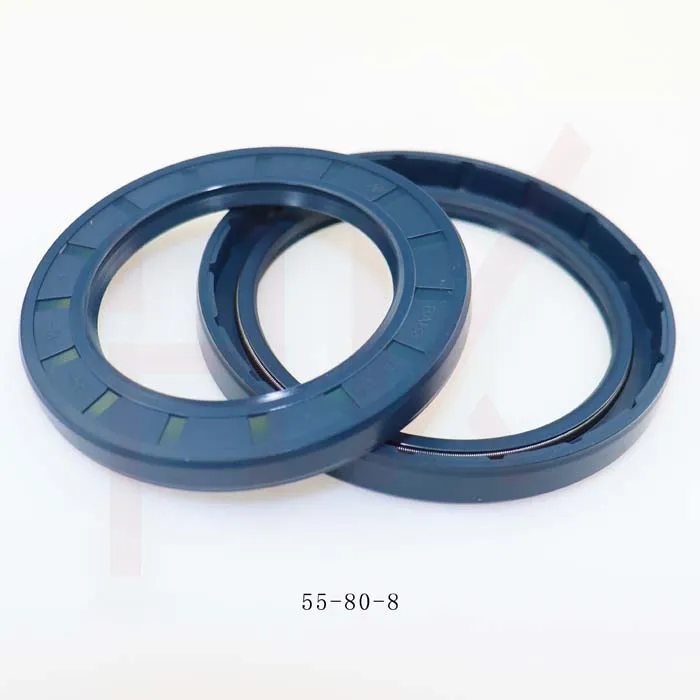

rubber seal kit

The Importance of Rubber Seal Kits in Industrial Applications

Rubber seal kits are essential components in a variety of industrial and mechanical applications. These kits are designed to provide reliable sealing solutions that prevent leaks and maintain pressure in machinery and equipment. From automotive applications to hydraulics, the significance of rubber seal kits cannot be overstated. This article explores the various aspects of rubber seal kits, including their components, benefits, and applications.

What are Rubber Seal Kits?

Rubber seal kits typically consist of a collection of seals, gaskets, and O-rings made from different types of rubber compounds. These components are engineered to fit specific applications and provide optimal sealing performance. The materials used in rubber seal kits can vary, including nitrile, silicone, neoprene, and fluorocarbon rubber, each offering unique properties tailored to specific environmental conditions.

Key Components of Rubber Seal Kits

1. O-Rings O-rings are circular rubber seals that fit into a groove and prevent the leakage of fluids and gases. They are versatile and can be found in various diameters and thicknesses to accommodate different applications.

2. Gaskets Gaskets are flat seals that fill the space between two or more mating surfaces to prevent leaks. They can be made from rubber or other materials, depending on the application’s requirements.

3. V-Rings and D-Rings These specialized seals are designed for unique applications, including rotary seals where traditional O-rings may not perform effectively.

4. Back-up Rings Used in conjunction with O-rings, back-up rings help prevent extrusion in high-pressure environments, extending the lifespan of the seal.

Benefits of Using Rubber Seal Kits

1. Leak Prevention One of the primary purposes of rubber seal kits is to prevent leaks of fluids and gases. This is crucial in maintaining operational efficiency and environmental safety.

2. Durability Rubber seals are engineered to withstand various environmental conditions, including extreme temperatures, chemicals, and pressures. This resilience makes them ideal for long-term use in demanding applications.

rubber seal kit

3. Cost-Effectiveness By preventing leaks and reducing downtime, rubber seal kits can lead to significant cost savings in maintenance and repairs. The initial investment in a quality seal kit is often offset by the reduction in operational costs over time.

4. Customization Rubber seal kits can be customized to fit specific requirements, ensuring that they meet the unique demands of various applications. This adaptability makes them suitable for industries ranging from automotive to aerospace.

5. Easy Installation Most rubber seal kits are designed for ease of installation, allowing for quick replacements and reducing the overall downtime of machinery.

Applications of Rubber Seal Kits

1. Automotive Industry Rubber seal kits are widely used in vehicles for sealing oil pans, engines, and transmissions, ensuring fluid retention and preventing leaks.

2. Hydraulics and Pneumatics In hydraulic systems, rubber seals are crucial for maintaining pressure and preventing fluid loss. They are commonly used in cylinders, pumps, and valves.

3. Construction Machinery Heavy equipment relies on rubber seal kits to ensure operational efficiency, particularly in environments exposed to dust, debris, and extreme weather conditions.

4. Aerospace In the aerospace industry, rubber seals are used in critical applications such as fuel systems and engine components, where reliability is paramount.

5. Medical Equipment Rubber seal kits are also utilized in medical devices to ensure sterile environments and prevent contamination.

Conclusion

Rubber seal kits play a crucial role in various industrial applications, providing reliable sealing solutions that enhance the performance and longevity of machinery and equipment. With their ability to prevent leaks, withstand harsh conditions, and be customized for specific applications, it is clear that rubber seal kits are indispensable in maintaining operational efficiency across multiple industries. Investing in high-quality rubber seal kits not only enhances the reliability of equipment but also contributes to significant cost savings in the long run.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories