Dec . 20, 2024 03:27 Back to list

hyd cylinder seals

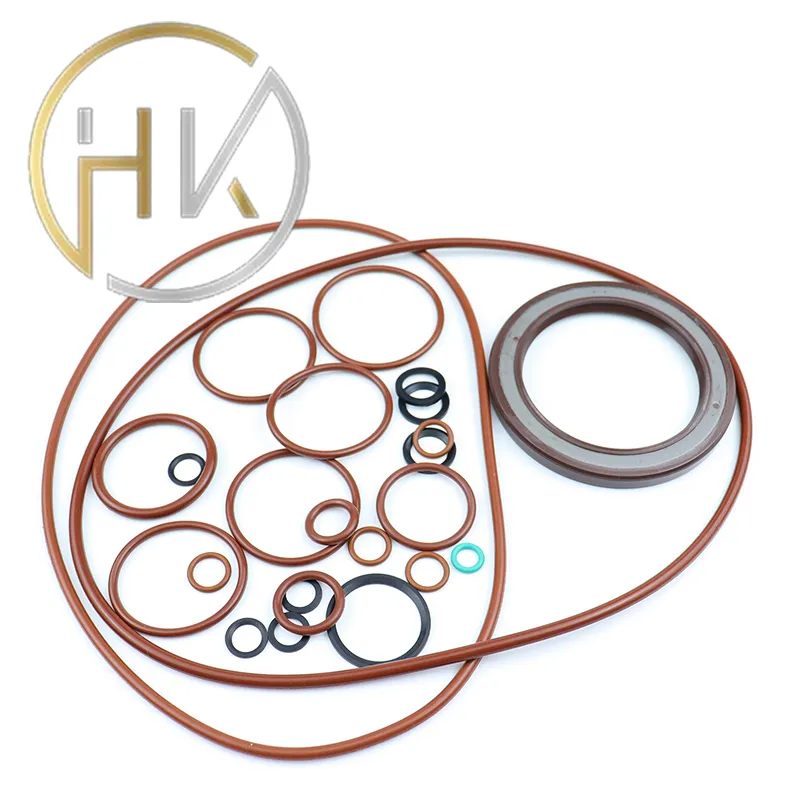

Understanding Hydraulic Cylinder Seals Essential Components for Fluid Power Systems

Hydraulic systems are integral to many industries, providing the necessary power to operate machinery and equipment. At the heart of these systems lie hydraulic cylinders, which convert hydraulic energy into mechanical force. However, the efficiency and reliability of hydraulic cylinders largely depend on one crucial component the seals. In this article, we will explore the significance of hydraulic cylinder seals, their types, functions, and the factors influencing their selection and maintenance.

The Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals serve multiple essential functions. Firstly, they create a barrier that prevents the hydraulic fluid from leaking out of the cylinder. This not only ensures that the hydraulic system maintains the required pressure, but also protects the environment from fluid contamination. Secondly, seals help retain the fluid within the cylinder, allowing the cylinder to generate force and perform work efficiently. Thirdly, seals minimize the ingress of contaminants—such as dirt, dust, and moisture—into the hydraulic system, which can lead to wear and failure if not adequately controlled.

Types of Hydraulic Cylinder Seals

There are several types of seals used in hydraulic cylinders, each designed for specific applications and performance requirements. The most common types include

1. Dynamic Seals These seals are designed to prevent fluid leaks and provide a tight seal between moving parts, such as the piston and cylinder bore. Examples include lip seals (or oil seals), U-cup seals, and V-rings. Dynamic seals are specifically engineered to handle the constant movement without compromising seal integrity.

2. Static Seals Static seals are used in applications where there is no movement between the sealing surfaces. They are typically employed to seal flanges, ports, and other stationary components within the hydraulic system. Examples include O-rings and gaskets.

3. Rod Seals Situated on the piston rod, these seals prevent hydraulic fluid from leaking out as the rod moves in and out of the cylinder.

hyd cylinder seals

5. Guiding Seals Also known as buffer seals, these are designed to protect the rod seal from external contaminants and assist in guiding the moving parts along their path.

Selecting the Right Hydraulic Cylinder Seal

Choosing the appropriate seal for hydraulic applications requires careful consideration of several factors, including

- Fluid Compatibility The material of the seal must be compatible with the hydraulic fluid used to prevent degradation and leakage.

- Temperature Range Hydraulic systems often operate under varying temperatures, so the seal must be able to withstand the heat without losing its effectiveness.

- Pressure Ratings The seal must be able to sustain the operational pressure of the hydraulic system.

- Movement Type The seal's design should accommodate the specific dynamic or static movements in the application.

Maintenance and Longevity

To ensure the longevity and performance of hydraulic cylinder seals, regular maintenance is crucial. Operators should routinely inspect seals for signs of wear, damage, or leakage. Implementing proper lubrication protocols, cleaning the surrounding areas, and promptly replacing worn seals can significantly enhance the service life of hydraulic components.

In conclusion, hydraulic cylinder seals are vital for the efficient operation of hydraulic systems. Their proper selection, maintenance, and understanding of their functions can greatly improve system reliability and productivity. By investing in quality seals and adhering to maintenance best practices, businesses can optimize hydraulic performance and minimize downtime, ultimately contributing to greater operational efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories