Sep . 16, 2024 17:46 Back to list

Engine Hoist Hydraulic Cylinder Rebuild Kit - High-Quality Replacement Parts

Rebuilding Hydraulic Cylinders for Engine Hoists A Comprehensive Guide

Hydraulic cylinders play a crucial role in the functionality of engine hoists, providing the necessary force to lift heavy engines and other components safely and efficiently. Over time, wear and tear can compromise the performance of these cylinders, leading to leaks or a reduction in lifting power. Fortunately, with the right tools and a reliable hydraulic cylinder rebuild kit, it’s possible to rejuvenate your engine hoist and extend its lifespan.

Understanding the Hydraulic Cylinder

The hydraulic cylinder is the heart of an engine hoist. It operates on the principle of hydraulics, where pressurized fluid is used to generate motion. When you pull the lever or push the button, hydraulic fluid flows into the cylinder, causing the piston to move and lift the load. However, seals and components within the cylinder can deteriorate due to prolonged use, exposure to dirt, and hydraulic fluid corrosion.

Signs of Cylinder Wear

Before proceeding with a rebuild, it’s essential to identify whether your hydraulic cylinder needs attention. Common signs include - Leaks Noticeable fluid accumulation around the cylinder. - Reduced Lifting Capacity Difficulty in lifting loads that were previously manageable. - Irregular Movement Jerky or uneven lifting, indicating that the piston is not functioning smoothly.

The Rebuild Process

1. Disassembly Start by safely lowering the hoist and disconnecting the hydraulic lines. Carefully disassemble the hydraulic cylinder, taking note of the arrangement of parts.

engine hoist hydraulic cylinder rebuild kit

2. Inspection Examine the internal components, including the piston, seals, and cylinder walls. Look for any signs of damage or excessive wear that may require replacement.

3. Cleaning Remove all old hydraulic fluid and clean all components using a suitable cleaner. This step is crucial to prepare the surfaces for new seals and ensure optimal performance.

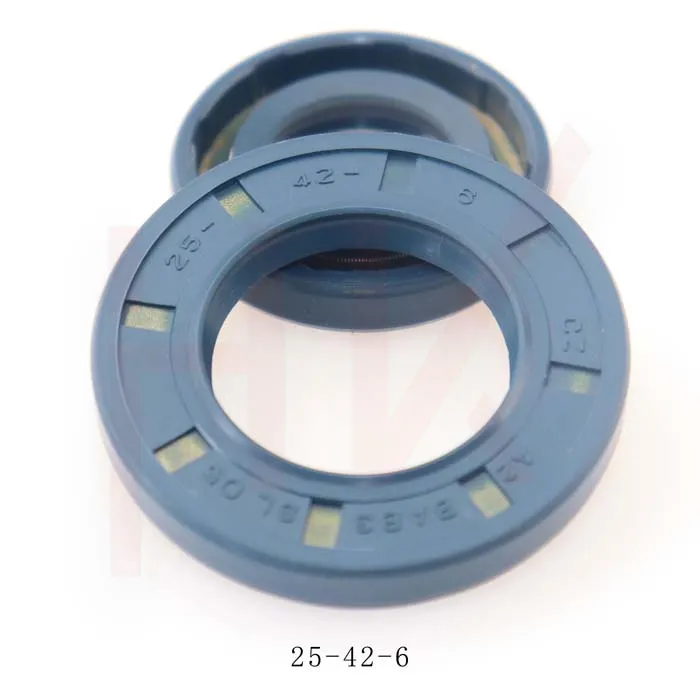

4. Replacement of Parts Using a rebuild kit specifically designed for your engine hoist model, replace any worn seals, O-rings, and other components. Ensure that you select high-quality parts to guarantee longevity.

5. Reassembly Carefully reassemble the cylinder, ensuring each part is fitted correctly. Follow manufacturer guidelines to avoid any misalignment that could lead to future issues.

6. Testing Once reassembled, connect the hydraulic lines and test the hoist at a safe load. Check for leaks and ensure smooth operation before putting it back into regular use.

Conclusion

Rebuilding your engine hoist's hydraulic cylinder is a cost-effective way to restore its functionality and avoid costly replacements. With a well-equipped hydraulic cylinder rebuild kit and a bit of mechanical aptitude, you can significantly enhance the performance of your hoist and ensure it continues to serve you well for years to come. Regular maintenance and timely rebuilds will promote safety and reliability in your garage or workshop.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories