Nov . 25, 2024 12:06 Back to list

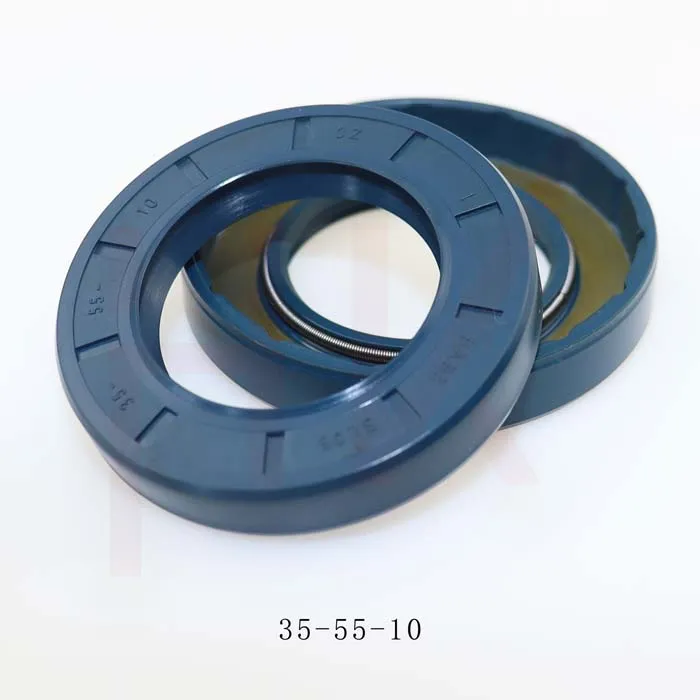

dust wiper seal

Understanding Dust Wiper Seals Importance and Applications

In various mechanical systems, particularly in heavy machinery and industrial equipment, dust wiper seals play a crucial role in maintaining operational efficiency and extending the life of components. These seals are designed to protect the internal workings of machinery from dust, dirt, and other contaminants, which can cause significant wear and tear over time. As industries continue to evolve, the significance of dust wiper seals becomes increasingly apparent, highlighting their essential function in lubrication systems, hydraulic cylinders, and other applications.

What are Dust Wiper Seals?

Dust wiper seals are specifically engineered components that are placed at the outermost part of a sealing system. Their primary function is to prevent dust and debris from entering critical zones, especially those that contain moving parts. They are usually made from durable materials with elastic properties, allowing them to adapt to variations in size and shape caused by movement and temperature changes. Typical materials used in manufacturing dust wiper seals include polyurethane, rubber, and silicone, each offering unique benefits depending on the application and environmental conditions.

Importance of Dust Wiper Seals

1. Protection Against Contaminants One of the primary roles of a dust wiper seal is to safeguard internal components from abrasive particles that could lead to premature failure. When contaminants enter machinery, they can scratch and pit surfaces, causing hydraulic systems to operate less efficiently and increasing energy costs.

2. Enhanced Lubrication Retention By keeping dust and debris out, dust wiper seals also help to maintain the integrity of lubricant systems. Proper lubrication is vital for minimizing friction between moving parts, reducing heat generation, and extending the lifespan of machinery. Without effective dust wiper seals, lubricants can become contaminated, leading to increased maintenance and operational costs.

dust wiper seal

3. Cost Efficiency Investing in high-quality dust wiper seals can significantly reduce the need for maintenance and repairs. Machinery that operates without proper protective seals is more likely to experience breakdowns, leading to costly downtime. By preventing contamination, companies can maintain higher productivity levels and save on repair costs in the long run.

4. Versatility Dust wiper seals are used in a wide range of applications across different industries, including construction, agriculture, automotive, and aerospace. Whether in hydraulic cylinders, pneumatic systems, or industrial machinery, these seals can be tailored to meet specific needs, accommodating various sizes and environmental conditions.

Applications of Dust Wiper Seals

In construction equipment, such as excavators and bulldozers, dust wiper seals are integral in protecting hydraulic cylinders from mud and dust, which are intrinsic to the operating environment. Similarly, in the agricultural sector, tractors and harvesters rely on these seals to prevent dirt from contaminating hydraulic systems, ensuring smooth operation even in challenging conditions.

In the automotive industry, dust wiper seals are crucial in keeping brakes and suspension systems free from contaminants that could impair functionality. They are also found in manufacturing equipment, like CNC machines, where precision is essential, and any dirt could compromise product integrity.

Conclusion

Dust wiper seals are a small but vital component in the machinery realm. Their ability to prevent contaminants from entering sensitive areas significantly enhances the efficiency and longevity of equipment. As industries recognize the value of these seals, they continue to be an integral part of engineering design and maintenance strategies. Investing in high-quality dust wiper seals is not merely a matter of compliance; it is a proactive measure towards sustainability, efficiency, and reliability in an increasingly competitive market. In conclusion, understanding and utilizing dust wiper seals effectively can lead to more resilient mechanical systems, contributing to overall business success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories