Sep . 24, 2024 20:39 Back to list

Exploring the Properties and Applications of 70% 2090% 2010% Oil Seal Compositions

Understanding the Significance of Oil Seals in Mechanical Applications

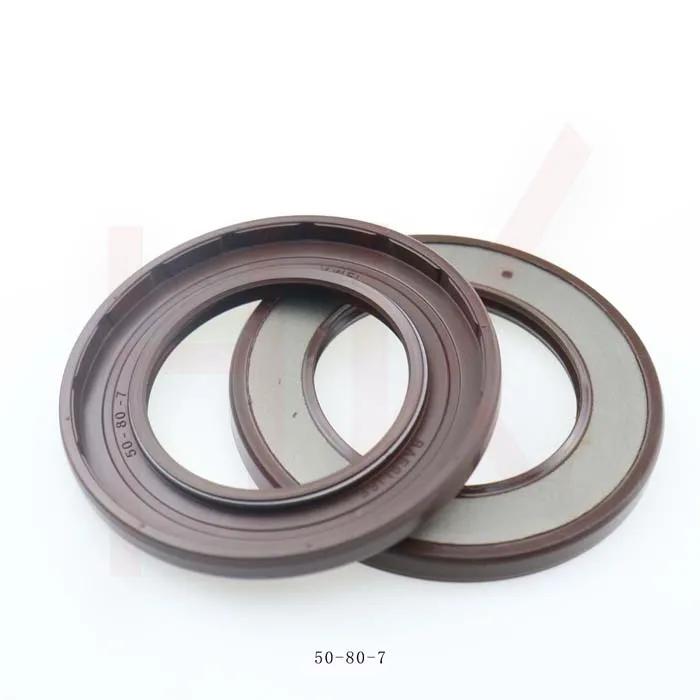

Oil seals, often referred to as shaft seals, play a crucial role in various mechanical applications, particularly in industries where rotational machinery is prevalent. A product comprised of both rubber and metal, oil seals are designed to ensure that lubricants within machinery remain contained, preventing leakage and contamination.

Understanding the Significance of Oil Seals in Mechanical Applications

In industrial machinery, where the assembly often operates at high speeds and under significant loads, the integrity of oil seals becomes even more critical. A failure in this component can lead not only to equipment downtime but also to costly repairs and maintenance. Hence, the durability and reliability of oil seals are paramount.

70 90 10 oil seal

One of the key metrics used to evaluate the effectiveness of oil seals is the percentage of leakage they can tolerate under specified conditions. For instance, in high-performance applications, a well-designed oil seal might aim for a leakage rate as low as 70% to 90% of the total oil used, ensuring that nearly all the lubricant remains within the system. This level of efficiency can significantly extend the life of the machinery and reduce operating costs.

Moreover, modern manufacturing technologies have enabled the production of oil seals that can withstand varying environments, including extreme temperatures and pressures. Materials such as fluorocarbon, silicone, and nitrile are commonly used, each offering distinct advantages based on the specific application requirements. For example, fluorocarbon-based seals are suitable for high temperatures and aggressive chemical environments, making them ideal for automotive and aerospace applications.

In conclusion, oil seals are integral components within mechanical systems, providing essential functions that enhance the performance and reliability of machinery. Understanding the different types of oil seals and their performance metrics is crucial for engineers and maintenance professionals. Selecting the right seal can mean the difference between optimal performance and premature mechanical failure, underscoring the importance of this seemingly small but vital part in the broader context of engineering and industrial operations. With continuous advancements in materials and design, the future of oil seals looks promising, paving the way for improved efficiency in a variety of applications.

-

Durable 22x35x6 TCV Oil Seals: FKM & NBR for Hydraulic Pumps

NewsSep.01,2025

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

Products categories