Sep . 25, 2024 11:47 Back to list

Alternative Oil Seal Specifications for 31x43x10 Percent and 205 Percent Variants

Understanding the 31x43x10 5 Oil Seal Significance and Applications

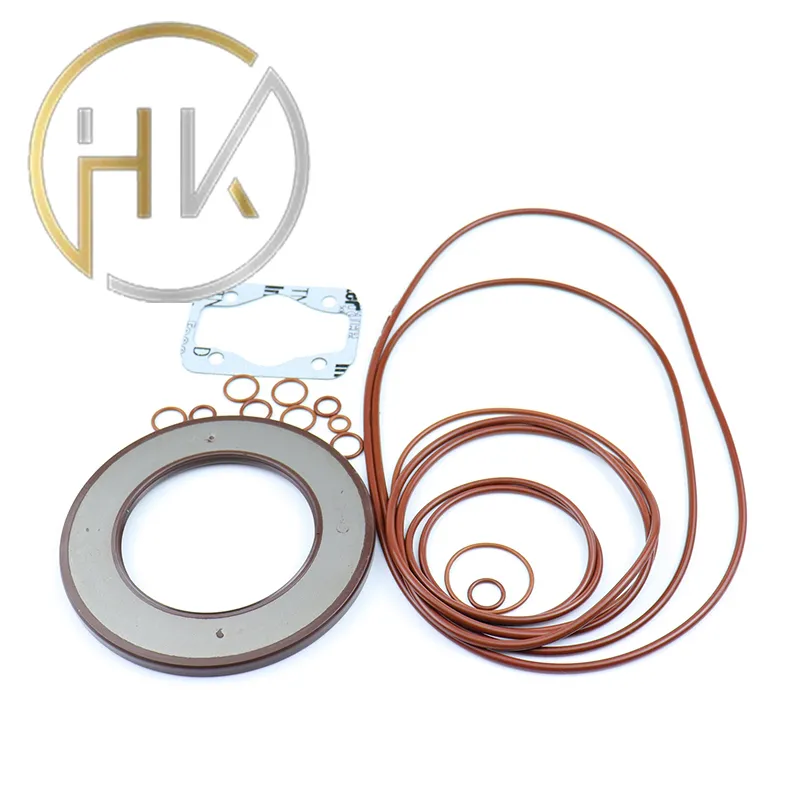

In the world of mechanical engineering, the importance of seals cannot be overstated. Among the various types of seals, the 31x43x10 5 oil seal stands out due to its specific dimensions and functionality. Oil seals, often referred to as rotary seals or lip seals, serve a critical role in preventing the leakage of lubricants and contaminants in machinery, ensuring efficiency and longevity.

Understanding the 31x43x10 5 Oil Seal Significance and Applications

Oil seals are primarily designed to retain lubrication within components while excluding dirt, dust, and moisture. In rotating machinery, oil seals are placed around shafts to maintain a lubricated environment, which reduces friction, minimizes wear, and enhances efficiency. An efficient oil seal not only improves the performance of the system but also extends the operational lifespan of the machinery.

31x43x10 5 oil seal

The materials used in the construction of the 31x43x10 oil seal are equally significant. Typically made from elastomers like nitrile rubber, viton, or silicone, these materials are chosen for their resilience and adaptability to various temperatures and chemicals. The choice of material significantly impacts the seal's performance, determining its resistance to oil, heat, and environmental factors.

Applications of the 31x43x10 oil seal are diverse. In the automotive sector, it is crucial in engines, gearboxes, and differentials, where maintaining a proper seal is vital to prevent oil leaks that could lead to catastrophic failure. Similarly, in industrial setups, these seals are paramount in preventing equipment failure due to lubricant loss.

In conclusion, the 31x43x10 5 oil seal is not merely a component; it is a significant player in enhancing machinery efficiency and reliability. Understanding its specifications, construction materials, and applications enables engineers and technicians to make informed choices that ensure optimal performance and durability. Investing in high-quality oil seals is a proactive step towards maintaining the integrity of mechanical systems, ultimately translating to reduced downtime and lower maintenance costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories