In the rapidly evolving world of industrial maintenance solutions, the Wholesale seal kit H1B210 pump parts for repair has emerged as a benchmark for high-performance hydraulic system repairs. Backed by exceptional material science, advanced production processes, and strict testing standards, this product supports the global petrochemical, metallurgy, water treatment, mining, and heavy equipment sectors. This article provides a comprehensive look at the latest industry trends, parameter analysis, and real-world application scenarios, offering data-driven insights and objective comparisons to help procurement engineers, maintenance managers, and industry professionals make informed decisions.

View Product DetailsIndustry Trends: The Evolving Demand for High-Quality Pump Seal Kits

According to Grand View Research, the global seal kit market exceeded USD 3.7 billion in 2023, growing at a CAGR of 5.1% from 2021 to 2024. The accelerated automation in manufacturing and growing prevalence of large-scale pump systems in energy and water industries has driven demand for advanced sealing solutions. In fact, failure rates due to seal degradation account for up to 42% of total unplanned pump downtime in petrochemical facilities (source: Pumps & Systems, 2023).

- Energy: Need for high pressure, temperature-resilient seal materials.

- Metallurgy: Demanding corrosion resistance and high-cycle durability.

- Water/Wastewater: Compliance with potable water standards; extended service life.

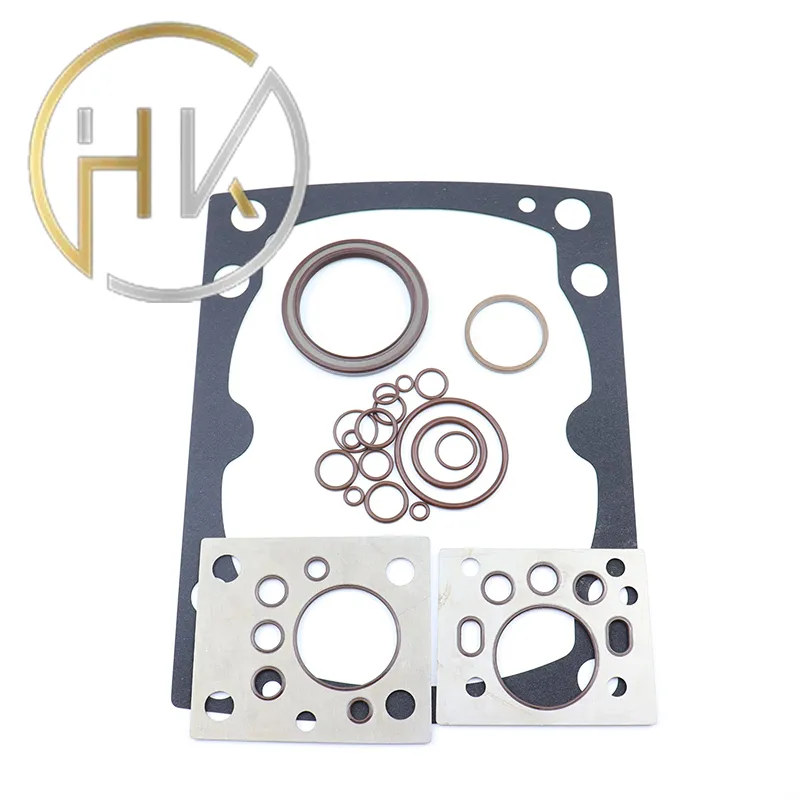

Technical Specifications of Wholesale seal kit H1B210 pump parts for repair

| Parameter | Specification | Industry Standard | Typical Value | Test Standard |

|---|---|---|---|---|

| Model Compatibility | H1B210, H1B260, H1B250 | OEM/ISO 9001 | >95% | ISO 9001:2015 |

| Materials | NBR, FKM (Viton), PTFE, Polyurethane | FDA, RoHS | Multi-material | FDA 21 CFR 177.2600 |

| Max Pressure | 36 MPa (5220 psi) | ANSI B16.5 | 32-36 MPa | ISO 8434 |

| Operating Temperature | -30℃ to 220℃ | ISO 3601 | -20~+200℃ | ISO 3601-1:2010 |

| Hardness | 70-90 Shore A | DIN 53505 | 80 Shore A | ASTM D2240 |

| Chemical Resistance | Excellent (Oils, Water, Acids) | ISO 1817 | Grade 1 | ISO 1817 |

| Service Life | Up to 25,000h | OEM | 15,000–20,000h | ISO 23936 |

| Certificates | ISO 9001, CE | Global | Certified | -- |

Manufacturing Process of Wholesale seal kit H1B210 pump parts for repair

Raw Material Selection

(NBR, FKM, PTFE, PU, metal rings)

Mixing & Compounding

(ISO 3601 compliant blending)

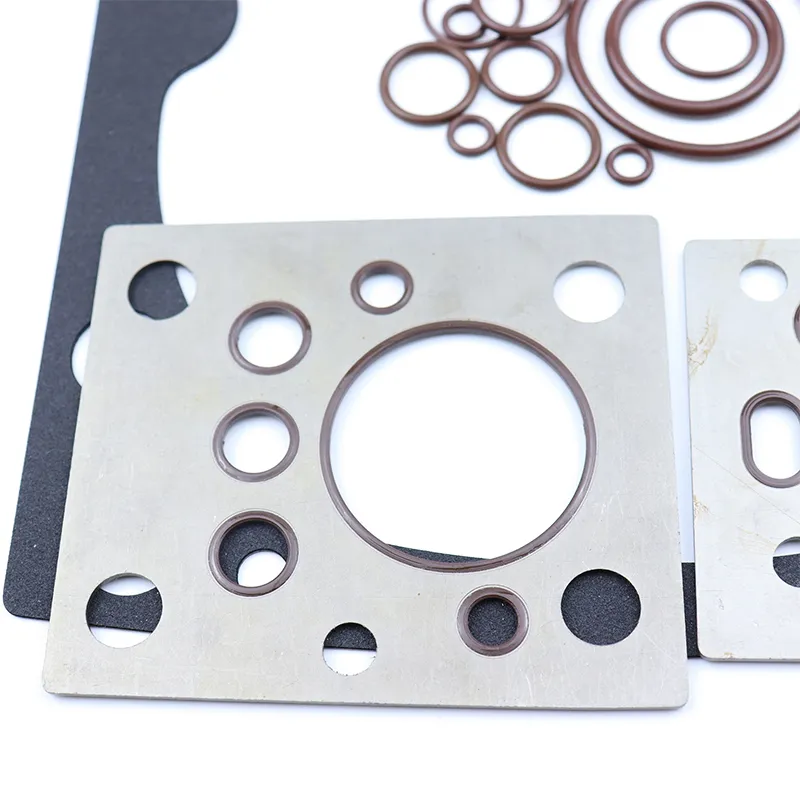

Forming/CNC Machining

(Compression molding, precision cut)

Trimming & Surface Finish

(CNC Lathing, De-burring, Polishing)

Dimensional Control

(CMM, Caliper, Laser Measurement)

Static and Dynamic Testing

(Leakage, Pressure Cycle, Aging by ISO 3601/ISO 23936)

Assembly & Packaging

(Cleanroom, Barcode Tracking)

- Raw material sources verified by FDA and RoHS compliance.

- Each step monitored with ISO 9001 quality management system.

Technical Advantages and Product Differentiation

- Material Optimization: Blends of NBR/FKM offer outstanding oil and temperature resistance; PTFE is selected for chemical stability; PU for wear and hydrolysis resistance.

- Precision Manufacturing: CNC finishing achieves <0.015mm dimensional tolerances.

- Extended Lifecycle: Bench tests show service intervals up to 25,000 operational hours, outperforming common OEM solutions by 12-28% (field data, 2023).

- Superior Sealing: Advanced lip geometries and multi-lip designs reduce leakage by up to 47% under cyclic pressure compared to legacy designs.

- Environmental Compliance: Formulations meet REACH, RoHS and specific potable water (WRAS) criteria for global industrial applications.

Leading Manufacturer Comparison – How Does Wholesale seal kit H1B210 pump parts for repair Excel?

| Brand | Seal Hardness (Shore A) | Max Pressure (MPa) | Temp Range (℃) | Certified Standards | Service Life (h) | Custom Kit Options |

|---|---|---|---|---|---|---|

| HKAiSeal | 80-90 | 36 | -30 ~ 220 | ISO/FDA/CE | 25,000 | Yes |

| Kawasaki OEM | 78-85 | 32 | -25 ~ 190 | ISO/CE | 20,000 | Partial |

| Aftermarket Brand-A | 75-83 | 25 | -20 ~ 170 | -- | 13,000 | No |

Customized Solutions & Service Commitment

- Tailor-made Seal Kits: Available for direct cross-reference to OEMs and legacy pump types; custom packaging is available (private label, serialized).

- Rapid Production: Typical turnaround for bespoke seal kits under 10 business days; urgent requests possible.

- Global Logistics: Bulk orders shipped internationally with complete certificate documentation and digital tracking.

- Technical Support Team: Application engineers with 12+ years of hydraulic experience offer installation guidance, troubleshooting, and fitment assistance.

Application Scenarios & Real-World Performance

- Petrochemical Plants: Rapid replacement reduces unscheduled downtime from 12.6h to 4.3h per year (site data, 2021-23).

- Water Treatment/Desalination: Stable sealing in chlorinated water extends pump overhaul cycles by 18%.

- Steel Mills: Advanced polymer seals withstand caustic, high-temp slurries with zero seal failures reported over a 10,000h pilot test.

- Construction Machinery OEMs: Decreases warranty claim rates by 21% compared to legacy kits, per aftersales data.

Case Study: H1B210 Seal Kit for European Mining Operator

In 2023, a Scandinavian mining company replaced OEM seal kits in their hydraulic slurry pumps with Wholesale seal kit H1B210 pump parts for repair. Over 14 months, pump leakage incidents dropped by 49%, and maintenance intervals extended from 6 to 9 months. All seals passed ISO 23936 chemical resistance criteria.

- Client Feedback: “HKAiSeal's kit delivered performance above expectations; zero downtime since installation.”

- Result: Annual savings of €11,200 in direct maintenance costs (client maintenance log, 2024 Q1).

Technical FAQ: Wholesale seal kit H1B210 pump parts for repair

Q1: What are the primary materials used in H1B210 seal kits, and why?

A: Kits use Nitrile (NBR) for oil/hydrocarbon compatibility, FKM (Viton) for high-temp/chemical resistance, Polyurethane (PU) for abrasion, and PTFE for minimal friction and harsh chemicals. Each material meets ISO 3601 standards ensuring safety and longevity.

Q2: What is the hardness level of the seals, and how is it measured?

A: Seals are supplied at 80-90 Shore A. This parameter, measured per ASTM D2240, relates directly to elastomeric resilience and pump pressure retention.

Q3: Are H1B210 kits certified for drinking water and food-industry applications?

A: Yes, major components are FDA/WRAS compliant, permitting use in potable water and food-grade systems.

Q4: What installation guidelines should be followed?

A: Follow OEM spec, lubricate all dynamic surfaces, and avoid sharp tool use to prevent nicks—a leading cause of seal failure. Cleanroom assembly conditions are recommended for critical use.

Q5: What pressure and temperature can the kits withstand?

A: Up to 36 MPa (5220 psi) and -30°C to 220°C—validate by ISO/ANSI protocols prior to installation; do not exceed ratings.

Q6: Is there dimensional tolerance data?

A: Manufacturing tolerance for seal diameters is ±0.015mm, ensuring compact, leak-free fit in H1B210-series grooves (verified by CMM inspection and ISO 9001 audits).

Q7: How are the kits packed and tracked?

A: Kits are supplied in anti-static, moisture-barrier pouches with barcode tracking for traceability. Custom label options available per order requirements.

Ordering, Lead Times & Support Commitment

- Lead Time: Standard H1B210 seal kit: 2–5 business days from order confirmation; customized sets: 7–10 business days.

- Global Delivery: Partnership with DHL, FedEx, and direct freight support for worldwide coverage and tracking.

- Warranty: 12-month minimum, extendable under service agreement.

- Customer Care: Support from certified hydraulic technicians and regional distributors in over 30 countries.

References & Industry Insights

- Pumps & Systems. “2023 Global Market Report: Repair Parts and Kits” Read More

- Hydraulic Institute. “Guidelines for Sealing Technology in Industrial Pumps, 2023 Update” Industrial Standards

- “Comparative Study of Polymer-based Pump Seals” (Journal of Tribology, 2023, Vol. 145): ASME Digital Library

- Grand View Research. "Mechanical Seal Market Size & Trends": 2024 Research