Sep . 23, 2024 04:13 Back to list

wiper seal hydraulic cylinder

Understanding Wiper Seals in Hydraulic Cylinders

Wiper seals play a crucial role in maintaining the efficiency and longevity of hydraulic cylinders. These components are essential in various applications, including construction machinery, agricultural equipment, and industrial machinery, where hydraulic systems are employed to generate and control powerful movements.

A wiper seal, also known as a dust seal or a scraper seal, is typically located at the outer end of a hydraulic cylinder. Its primary function is to prevent dirt, dust, and other contaminants from entering the cylinder, while also retaining lubrication and hydraulic fluid inside. The integrity of hydraulic systems depends heavily on clean environments, making the wiper seal a vital element in the overall performance.

Functions and Importance

The main role of a wiper seal is to protect the internal components of a hydraulic cylinder from external contaminants. When a cylinder is in operation, various particles, including dirt, dust, and debris, can accumulate on the piston rod. If these particles enter the cylinder, they can cause significant damage to the internal seals, leading to leaks and ultimately system failure.

Moreover, wiper seals help maintain the efficiency of hydraulic systems by ensuring that hydraulic fluid remains within the cylinder. This is crucial for optimal performance, as the hydraulic fluid provides necessary lubrication for the moving parts. A compromised seal can result in fluid loss, reduced pressure, and less effective operation of the machinery.

Types of Wiper Seals

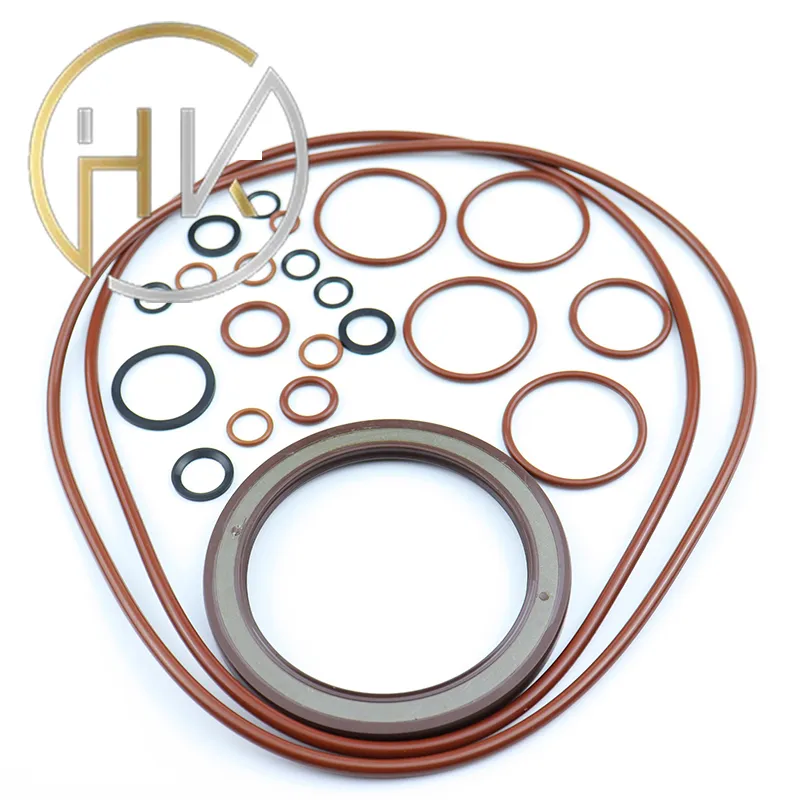

wiper seal hydraulic cylinder

Wiper seals come in various designs and materials, tailored to meet specific operational requirements. Common materials include nitrile rubber, polyurethane, and silicone, each offering unique properties such as resistance to temperature extremes, chemicals, and wear.

1. Nitrile Rubber Seals These are widely used due to their excellent resistance to oil and hydraulic fluids. They are well-suited for a range of environments but may degrade under extreme temperatures.

2. Polyurethane Seals Known for their durability and resistance to abrasion, polyurethane wipers are ideal for high-load applications. They exhibit superior performance in dirty conditions, making them suitable for construction and mining equipment.

3. Silicone Seals Although less common, silicone wiper seals are used in environments experiencing high temperatures. They retain their elasticity and effectiveness even under severe conditions.

Maintenance and Inspection

Regular inspection and maintenance of wiper seals are essential to prolong the lifespan of hydraulic cylinders. Operators should routinely check for signs of wear, such as cracks, tears, or extrusions. Keeping the working environment clean and ensuring that the hydraulic system is free from leaks will also enhance the effectiveness of the wiper seals.

In conclusion, wiper seals are indispensable in the functionality of hydraulic cylinders. Understanding their purpose, types, and maintenance needs can significantly improve the reliability and efficiency of hydraulic systems, leading to greater productivity and reduced operational costs in various industry sectors. By investing in quality wiper seals and ensuring their proper maintenance, operators can safeguard their equipment effectively.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories