Oct . 18, 2024 19:20 Back to list

Understanding the Function and Importance of Wiper Seals in Hydraulic Cylinders

Understanding Wiper Seals in Hydraulic Cylinders

Hydraulic cylinders are crucial components in various machinery and equipment, playing a pivotal role in converting hydraulic energy into linear motion. An often overlooked but vital part of hydraulic cylinders is the wiper seal. This article delves into the significance of wiper seals, their function, types, and maintenance, all contributing to the efficient performance of hydraulic systems.

What is a Wiper Seal?

A wiper seal is an essential sealing element installed at the rod end of hydraulic cylinders. Its primary function is to prevent contaminants such as dirt, dust, and moisture from entering the hydraulic system while simultaneously ensuring the hydraulic fluid does not escape. The design and material of wiper seals are critical, as they are subjected to harsh operating conditions, including high pressures and temperatures.

Functions of Wiper Seals

1. Contaminant Prevention The primary purpose of a wiper seal is to act as a barrier against foreign particles. When hydraulic cylinders operate, they extend and retract, which can create a dynamic environment where external materials may easily enter. By efficiently blocking such contaminants, wiper seals help maintain the cleanliness of the hydraulic fluid, reducing wear and tear on the internal components of the cylinder.

2. Fluid Retention Although wiper seals are primarily designed to keep outside contaminants out, they also play a role in ensuring that hydraulic fluid remains within the cylinder. Effective sealing prevents leaks, maintaining the pressure needed for optimal hydraulic performance.

3. Protection of Other Seals Wiper seals also protect other sealing elements, such as rod seals, from exposure to debris and dirt. By keeping the primary seals clean, wiper seals contribute to the longevity and reliability of the entire hydraulic system.

Types of Wiper Seals

Wiper seals can be classified into several types based on their design and material composition. Some of the common types include

1. U-Cup Wiper Seals These seals have a U-shaped design that allows them to fit snugly around the rod. Their configuration provides excellent wiping action and is commonly used in various hydraulic applications.

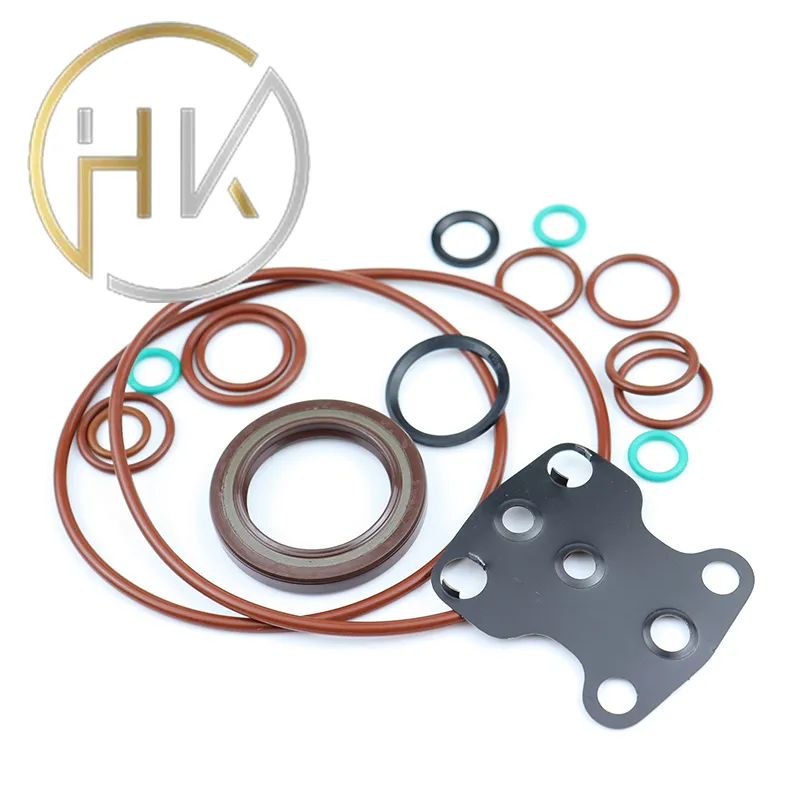

wiper seal hydraulic cylinder

2. Blade Seals Blade wipers feature a flat wiping edge that makes contact with the rod. While they are simple in design, they effectively remove contaminants and are often used in lighter-duty applications.

3. T-Seals T-seals offer a combination of sealing and wiper functions. Their design provides an efficient barrier against contaminants while also retaining hydraulic fluid.

4. Composite Seals These are made from a combination of materials, providing enhanced durability and resistance to wear and temperature extremes. They are ideal for high-performance hydraulic systems operating under challenging conditions.

Maintenance and Inspection

Regular maintenance and inspection of wiper seals are vital for the longevity of hydraulic systems. Here are some key practices

1. Visual Inspection Regularly examine the wiper seals for any signs of wear, cracking, or damage. Early detection of issues can prevent costly repairs and downtime.

2. Cleaning Keeping the area around the wiper seals clean is essential. Debris buildup can lead to seal failure, so using compressed air or other cleaning methods to remove dirt is advisable.

3. Lubrication Applying a suitable lubricant can enhance the performance of wiper seals. However, care should be taken to use compatible products that do not degrade the seal materials.

4. Replacement Wiper seals do have a finite lifespan. If wear or damage is apparent, they should be replaced promptly to maintain hydraulic system integrity.

Conclusion

Wiper seals are a small yet significant component of hydraulic cylinders, playing crucial roles in maintaining system efficiency and performance. By understanding their functions, types, and the importance of regular maintenance, operators can ensure that their hydraulic systems run smoothly, prolonging the life of machinery and preventing costly breakdowns. Taking the time to appreciate these components underscores the complex but fascinating world of hydraulic engineering, where every detail contributes to overall efficiency and reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories