Nov . 08, 2024 09:06 Back to list

Understanding the Function and Importance of Wiper Ring Seals in Machinery

The Importance of Wiper Ring Seals in Hydraulic Systems

Wiper ring seals are essential components in hydraulic systems, playing a crucial role in maintaining system efficiency and longevity. As mechanical systems evolve and require more precise components, the significance of wiper rings becomes even more pronounced. This article will explore the features, functions, applications, and maintenance of wiper ring seals, shedding light on their integral role in various industries.

What are Wiper Ring Seals?

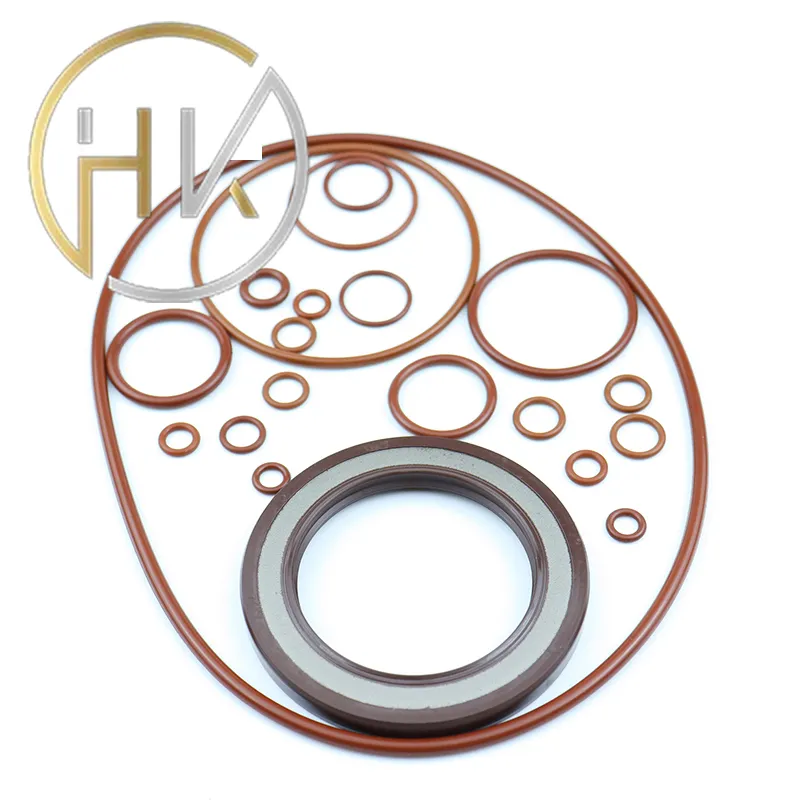

Wiper ring seals, often referred to as scraper seals or wiper seals, are designed to remove contaminants from the surface of hydraulic rods or pistons. They are typically installed in hydraulic cylinders, where they prevent dirt, dust, and other debris from entering the hydraulic system. Wiper rings are constructed from durable materials like polyurethane or nitrile rubber, allowing them to withstand harsh environments and maintain their sealing properties over time.

Functions of Wiper Ring Seals

The primary function of a wiper ring seal is to keep the hydraulic system clean. By scraping away contaminants from the rod or piston surface, these seals help to prevent damage to other components in the hydraulic system. Contaminants can lead to wear and tear on seals, pistons, and cylinders, which can result in leaks, decreased efficiency, and ultimately system failure.

In addition to keeping surfaces clean, wiper ring seals also contribute to the overall performance of a hydraulic system. They help maintain pressure within the system by preventing leakage of hydraulic fluid. This is essential for the efficient operation of hydraulic machinery, where precise control over fluid movement is required for effective functioning.

Applications of Wiper Ring Seals

Wiper ring seals are widely used across various industries, showcasing their versatility and importance. In the construction industry, for instance, they are found in hydraulic excavators, loaders, and dump trucks, where they protect hydraulic cylinders from dust and debris encountered on job sites.

wiper ring seal

In the automotive sector, wiper seals are used in hydraulic brake systems and power steering systems, ensuring that these critical components operate smoothly without contamination. Additionally, wiper ring seals are essential in manufacturing equipment, aerospace applications, and agricultural machinery, where their ability to enhance performance and reliability is crucial.

Choosing the Right Wiper Ring Seal

When selecting a wiper ring seal for a specific application, several factors must be considered, including material compatibility, temperature range, and pressure specifications. The choice of material is critical, as it influences the seal's durability and its ability to resist wear from contaminants. For example, polyurethane wiper seals are ideal for moderate temperature applications due to their excellent abrasion resistance.

Additionally, the design of the wiper ring can vary. Some designs feature a lip that effectively scrapes debris, while others might have a more complex geometry to enhance sealing capabilities. Understanding the application and operational conditions will guide users in selecting the appropriate wiper seal.

Maintenance and Longevity of Wiper Ring Seals

Proper maintenance plays a vital role in extending the life of wiper ring seals. Regular inspection of hydraulic systems is essential to identify wear and tear on seals, followed by timely replacements when necessary. Ensuring that hydraulic fluids are free from contaminants will also significantly enhance the performance and lifespan of wiper seals.

Moreover, using clean installation practices will prevent the introduction of debris during assembly, which can compromise seal integrity. It’s also advisable to follow the manufacturer's guidelines for installation and maintenance to ensure optimal performance.

Conclusion

Wiper ring seals are critical components that ensure the efficiency and reliability of hydraulic systems across various industries. By effectively removing contaminants and maintaining pressure, these seals contribute significantly to the performance and longevity of hydraulic machinery. As technology advances and demands on hydraulic systems increase, the importance of high-quality wiper seals continues to grow. Investing in the right wiper ring seals and implementing proper maintenance practices can lead to improved system performance, reduced downtime, and ultimately, significant cost savings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories