Jan . 23, 2025 00:44 Back to list

wiper ring piston

From a user experience perspective, the longevity of a wiper ring piston can significantly affect maintenance schedules and engine performance. Reliable data from field experience indicates that engines fitted with high-quality wiper ring pistons require less frequent oil changes and exhibit reduced deterioration of oil quality. This benefit not only extends the lifespan of the engine but also enhances its fuel efficiency, which is a critical factor for both individual vehicle owners and commercial fleets aiming to minimize operating costs. Expertise in installation also plays a significant role. Proper installation and maintenance of wiper ring pistons necessitate skilled technicians who understand the nuances of different engine models. These professionals use precision tools to measure and ensure correct piston ring gap sizes, which is vital for optimal function. Misalignment or incorrect installation can lead to a host of issues, including reduced engine efficiency and increased oil consumption. The authoritative voices in automotive engineering continually stress the evolution and advancements in wiper ring piston technology. As the industry moves towards more eco-friendly practices, the development of materials and designs that contribute to reduced emissions and improved fuel economy are paramount. Cutting-edge technologies are emerging, such as diamond-like carbon (DLC) coatings, offering even greater reductions in friction, thus enhancing performance and efficiency. In conclusion, the significance of the wiper ring piston cannot be overstated. It embodies a combination of experience-backed design, material engineering expertise, authoritative manufacturing processes, and trustworthy performance. Whether for conventional gasoline engines or new hybrid models, the advancement and selection of high-quality wiper ring pistons remain crucial. As global trends push towards sustainability, the role of these pistons is likely to grow, presenting even more opportunities for innovation in engine technology. For any automotive manufacturer, understanding and investing in developing superior wiper ring piston components is an investment in reliability, efficiency, and environmental responsibility.

-

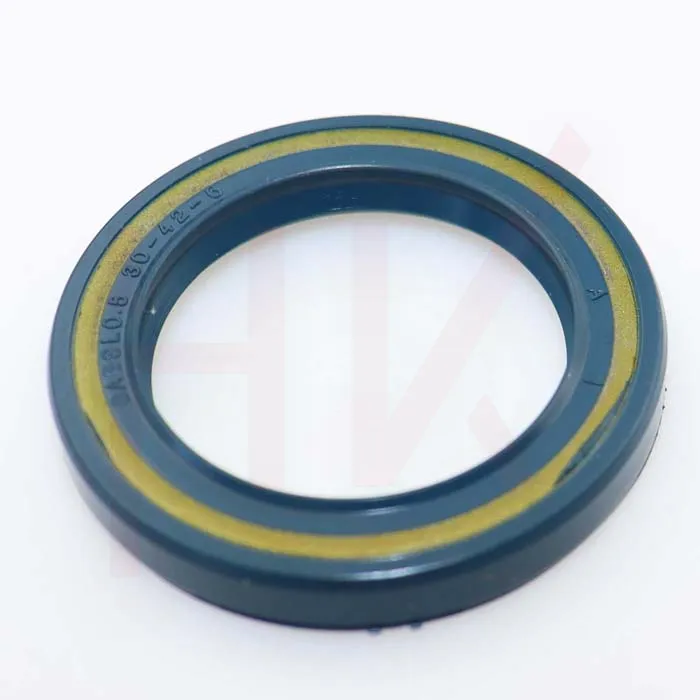

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories