Nov . 21, 2024 03:21 Back to list

wiper ring piston

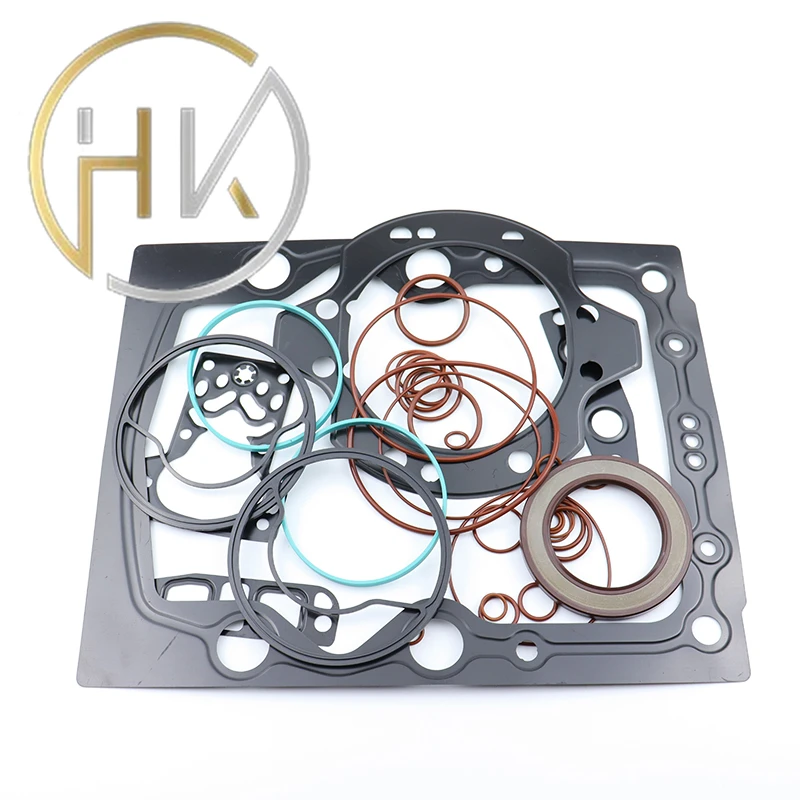

Understanding Wiper Ring Pistons Function, Design, and Application

In the world of engineering, the quest for efficiency and reliability in machines is never-ending. A crucial component that plays a significant role in various mechanical systems is the wiper ring piston. This essential part may not always be visible or prominently acknowledged, but it performs critical functions that ensure the smooth operation of engines, hydraulic systems, and other machinery.

What is a Wiper Ring Piston?

The wiper ring piston is a type of sealing device that is typically used in hydraulic cylinders. It is designed to fit snugly into a cylindrical housing, creating a tight seal that prevents fluid leakage while allowing for the movement of the piston. Commonly made from materials such as rubber, polyurethane, or PTFE (Teflon), the wiper ring features a flexible design that can conform to varying surface conditions. It serves primarily to wipe and clean the rod as it exits or enters the cylinder, while also maintaining pressure within the system.

Key Functions of Wiper Ring Pistons

1. Sealing The primary function of the wiper ring is to create a seal. This prevents hydraulic fluid from escaping the system, which is crucial for maintaining pressure and ensuring efficient operation.

2. Wiping Debris As the piston moves, dirt and debris can accumulate on the cylinder rod. The wiper ring acts like a brush, cleaning the rod as it moves in and out. This prevents contaminants from entering the hydraulic system, which could lead to hydraulic failure and reduced performance.

3. Extending Component Life By keeping dirt and grime away from critical components, the wiper ring helps to prolong the life and performance of the hydraulic cylinder and associated machinery. This reduction in wear can lead to lower maintenance costs and increased efficiency.

wiper ring piston

Design Considerations

The design of a wiper ring piston is crucial to its function. Factors such as material choice, hardness, and geometry all influence its effectiveness. The choice of material depends on several aspects, including temperature range, fluid compatibility, and exposure to environmental conditions. For instance, PTFE is known for its chemical resistance and can endure high temperatures, making it an ideal choice for demanding applications.

The geometry of the wiper ring is also vital. A proper fit is necessary to ensure effective wiping and sealing. Engineers must meticulously calculate the dimensions to account for tolerances in manufacture and the expected wear over time. Furthermore, the design may vary depending on the application, and options such as different cross-sectional shapes—round, square, or specially contoured—can enhance performance in specific scenarios.

Applications of Wiper Ring Pistons

Wiper ring pistons are used in a myriad of applications across various industries. In hydraulic systems, they are found in excavators, forklifts, and industrial machinery. In automotive engines, they function to help maintain pressure and prevent leaks in hydraulic brake systems and power steering mechanisms. They are also widely utilized in aerospace applications, where reliability and performance are of utmost importance.

The versatility of wiper ring pistons extends into consumer appliances as well, aiding in products that require movement along a shaft while minimizing wear and maintaining cleanliness.

Conclusion

In summary, the wiper ring piston is a vital component in a wide array of mechanical systems. Its ability to seal, wipe debris, and extend the life of machinery cannot be overstated. Through careful design and material selection, engineers can develop effective wiper rings that improve the reliability and efficiency of hydraulic systems. As industries continue to push the boundaries of technology and efficiency, the role of such components will only become more pronounced, emphasizing the importance of understanding and optimizing their use in various applications. Whether in heavy machinery or everyday appliances, the humble wiper ring piston is an example of how even the smallest components can have a significant impact on performance and longevity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories