Feb . 17, 2025 22:59 Back to list

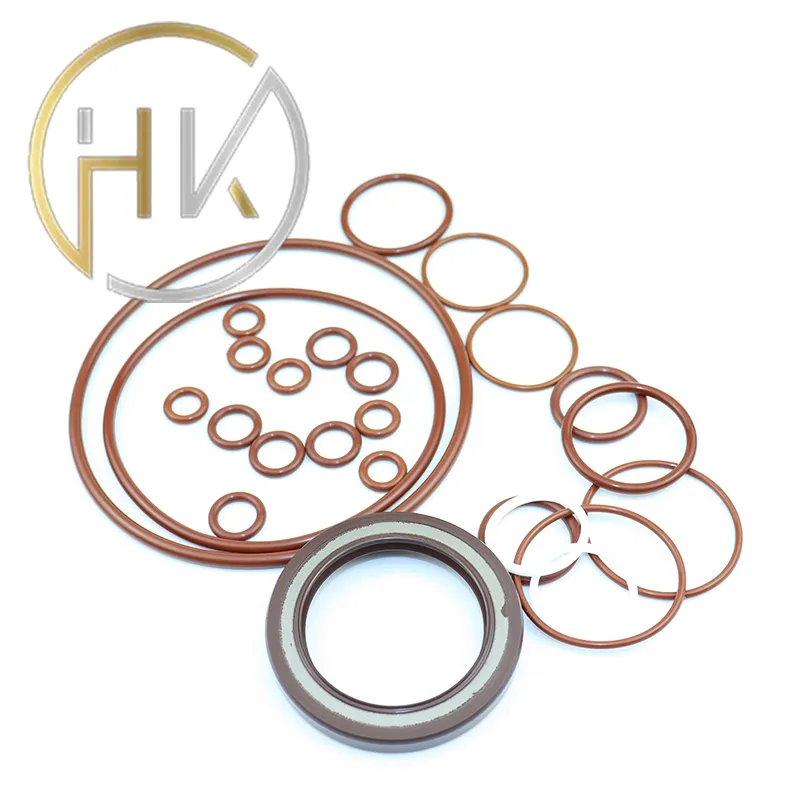

wiper seals

3. Lubrication Appropriate lubrication minimizes friction and resistance during operation. Consult the manufacturer’s guidelines to determine which lubricants are compatible with your specific wiper ring material. 4. Environmental Considerations Every environment imposes unique stressors on equipment. For harsh conditions, ensure the rings you use are resilient to these specific environmental factors. Whether it be extreme temperatures or chemical exposure, selecting the right material composition is crucial. How Manufacturers are Innovating Wiper Rings As technological advancements surge forward, manufacturers continually innovate to enhance the efficacy of wiper rings. For instance, the latest designs incorporate multi-lip configurations which provide superior sealing qualities. I've had the opportunity to work with a team that pioneered a new type of self-lubricating wiper rings. This advancement reduced the need for additional service lubricants while maintaining smooth operation and reducing maintenance costs. Additionally, some contemporary wiper rings feature embedded sensors that monitor and report performance parameters, offering predictive maintenance insights. This development, in which I was involved as a technical consultant, has shown that real-time data not only extends the lifecycle of equipment but also facilitates efficient maintenance scheduling. Why Trust the Experts? When it comes to selecting the right wiper ring for your hydraulic or pneumatic systems, experience, and expertise are invaluable. An informed choice ensures efficiency, performance, and cost-effectiveness. Throughout my career, I have collaborated with top-tier manufacturers to develop cutting-edge solutions. The insights gained from these collaborations allow me to confidently propose the most suitable materials and designs tailored to specific operational needs. Invest in wiper rings not as a minor component but as an essential component of your machinery. With the right expertise and informed choice, these small but significant parts can maximize performance and longevity. Therefore, when faced with a decision, consult with seasoned experts to leverage their experience and make a choice that optimizes both current operations and long-term investments.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories