Sep . 03, 2024 13:42 Back to list

wiper seal types

Understanding Wiper Seal Types An Essential Component for Machinery

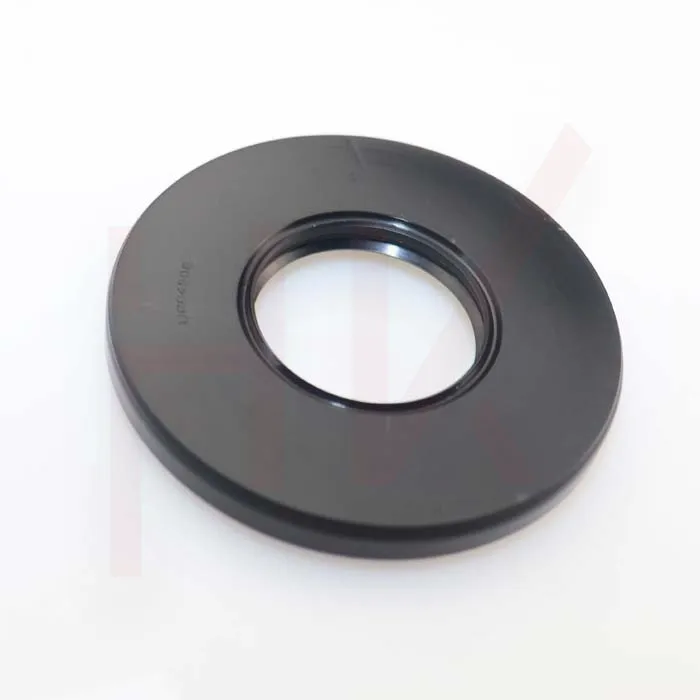

Wiper seals are crucial components widely used in hydraulic and pneumatic systems, ensuring that contaminants are kept out of critical areas while retaining lubrication within. The effectiveness of these seals is vital for the performance and longevity of machinery. Various types of wiper seals exist, each designed to meet specific operational requirements. Understanding these different types is essential for choosing the right seal for any application.

Understanding Wiper Seal Types An Essential Component for Machinery

Another popular option is the sweeper seal. This seal is similar to a lip seal but includes an additional feature that aids in the removal of accumulated dirt and grime. Sweeper seals are particularly beneficial in environments where heavy dust, mud, or other particulates are present. Their design allows for better performance in harsh conditions, ensuring that machinery operates smoothly without risking damage from foreign materials.

wiper seal types

U-cup seals are another variation that provides a robust sealing solution. The U-shaped design allows for easy installation and effective sealing against high pressures. These seals are versatile and can be used in both dynamic and static applications. Their ability to accommodate slight misalignments makes them ideal for machinery subjected to varying loads and movement.

X-ring seals are also gaining popularity due to their superior sealing capabilities. Often used in applications requiring a higher resistance to wear and deterioration, the X-ring can provide a more effective seal compared to conventional O-rings. The design enhances the seal's ability to handle increased pressure while minimizing friction, making it suitable for high-speed applications.

Choosing the right wiper seal type is critical for maintaining machinery efficiency and longevity. Factors such as the working environment, pressure ratings, and the type of fluid being sealed should all be considered. By selecting the appropriate wiper seal, operators can significantly reduce maintenance costs and enhance the reliability of their equipment. Understanding the complexities and functionalities of various wiper seal types ensures that users can make informed decisions tailored to their specific needs, leading to improved operational performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories