Dec . 20, 2024 21:11 Back to list

wheel oil seal

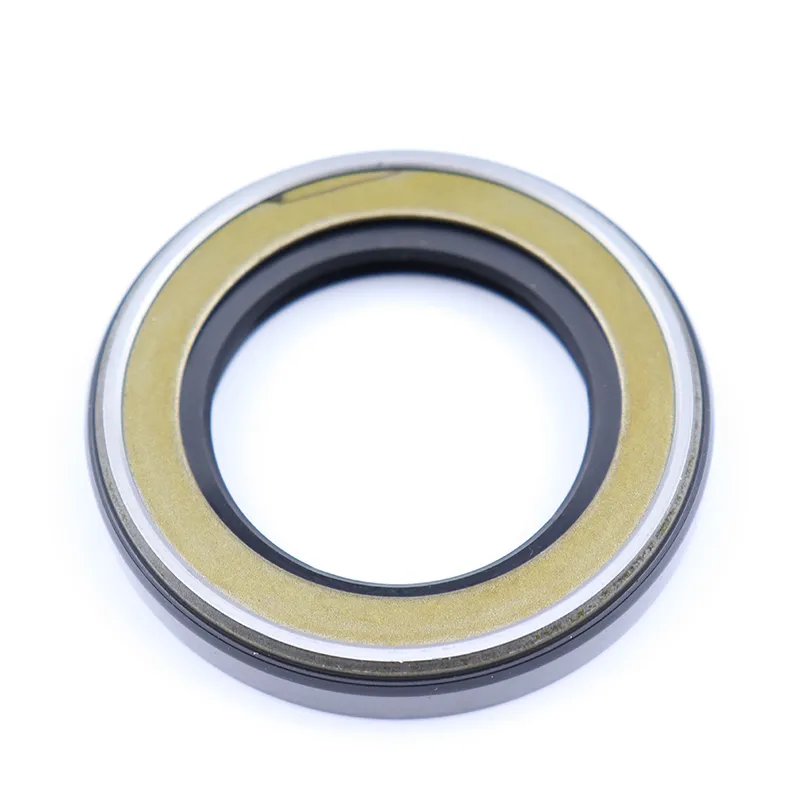

Understanding Wheel Oil Seals Their Function and Importance

Wheel oil seals, often overlooked in automotive maintenance, play a crucial role in ensuring the longevity and efficiency of vehicle performance. These seals act as a barrier, preventing oil leakage from the wheel bearings and keeping dirt and moisture at bay. In this article, we will explore the function, types, and importance of these essential components.

What Are Wheel Oil Seals?

Wheel oil seals are specialized components made from materials like rubber or silicone, designed to maintain the integrity of the wheel assemblies in vehicles. They are installed in the wheel hubs, where they seal off the bearings from the surrounding environment. Seals help maintain the necessary lubrication within the bearings, ensuring smooth operation while protecting these vital components from contamination.

Functions of Wheel Oil Seals

1. Prevent Oil Leakage The primary function of wheel oil seals is to prevent the wheel bearing lubricant from leaking out. Lubrication is essential for reducing friction and wear, thus ensuring the smooth functioning of the wheel assembly.

2. Keep Contaminants Out Oil seals also protect the bearings from external contaminants such as dust, dirt, and moisture. These particles can lead to rust and corrosion, significantly shortening the lifespan of the bearings.

Types of Wheel Oil Seals

There are several types of wheel oil seals available, each designed for specific applications. Here are a few commonly used types

wheel oil seal

1. Single Lip Seals These seals feature a single sealing lip and are generally used in low-speed applications. They are easier to install and are suitable for many standard vehicles.

2. Double Lip Seals Equipped with two sealing lips, double lip seals provide enhanced protection against contaminants and are often used in high-performance and heavy-duty vehicles.

3. Spring-Loaded Seals These seals include a spring mechanism that helps maintain contact with the mating surfaces, ensuring an effective seal even during thermal expansion or contraction.

Importance of Wheel Oil Seals

The importance of wheel oil seals cannot be overstated. Neglecting the condition of these components can result in the following issues

- Increased Wear and Tear Without proper sealing, lubrication can escape, leading to increased friction and wear on bearings. This can eventually result in bearing failure and costly repairs.

- Reduced Performance Compromised seals can lead to overheating and reduced efficiency in vehicle performance. This not only affects the vehicle's handling but can also impact fuel efficiency.

- Safety Hazards Oil leaking from the wheel assembly can pose safety risks, such as reduced braking efficiency or loss of control while driving. This underscores the importance of regular maintenance checks.

Conclusion

Wheel oil seals are a vital component of a vehicle’s wheel assembly, ensuring that lubrication remains intact and contaminants are kept outside. Regular inspection and maintenance of these seals can prevent severe damage to the wheel bearings, improve vehicle performance, and enhance overall safety. Vehicle owners should prioritize the health of their wheel oil seals as part of their routine maintenance to ensure a safe and efficient driving experience. By understanding the role and importance of wheel oil seals, drivers can better appreciate these often-overlooked parts of their vehicles.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories