Nov . 14, 2024 09:15 Back to list

wheel hub grease seal

Understanding Wheel Hub Grease Seals Importance, Types, and Maintenance

Wheel hub grease seals are essential components in the automotive and machinery sectors, playing a vital role in ensuring the proper functioning and longevity of wheel bearings. These seals are designed to retain grease within the wheel hub while preventing dirt, debris, and moisture from entering, which could potentially lead to bearing failure. In this article, we will examine the importance of grease seals, the various types available, and maintenance tips to ensure their longevity.

Importance of Wheel Hub Grease Seals

The primary function of wheel hub grease seals is to protect the lubricating grease that keeps wheel bearings functioning optimally. Wheel bearings allow the wheel to rotate smoothly, supporting the vehicle’s weight. The grease within the hub not only lubricates the bearings but also dissipates heat generated during wheel rotation, thereby preventing overheating and damage.

If grease seals fail, they can cause the grease to leak out, leading to insufficient lubrication. This condition can result in increased friction, overheating, and ultimately, bearing failure. Furthermore, contaminants such as dirt and water can infiltrate the hub, leading to corrosion and further damage. Thus, effective grease seals are critical for promoting durability, enhancing vehicle performance, and ensuring safety.

Types of Wheel Hub Grease Seals

There are several types of wheel hub grease seals, tailored to meet specific application requirements

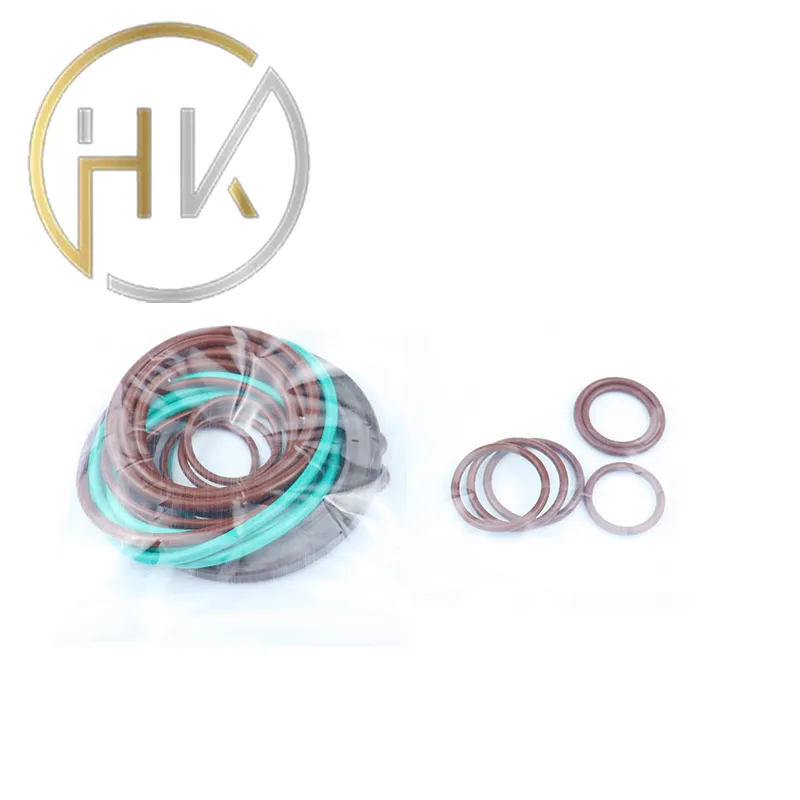

. The most common types include1. Rubber Lip Seals These are the most widely used grease seals. They consist of a rubber outer lip that creates a tight seal against the hub while allowing some flexibility to accommodate movement and temperature changes.

2. Spring-Loaded Seals Similar to rubber lip seals, these seals come with a spring that adds extra tension to the sealing lip. This design ensures a better seal against contaminants and is particularly useful in high-speed applications.

3. Metal Seals These seals are made from durable metals and are often used in applications where extreme environmental conditions exist. They offer high resistance to wear and can withstand elevated temperatures and pressures.

wheel hub grease seal

4. Composite Seals Made from a combination of materials, composite seals are designed to offer enhanced performance in unique environments, balancing durability with flexibility.

Maintenance Tips

To ensure the longevity and effectiveness of wheel hub grease seals, regular maintenance is crucial. Here are some tips

1. Regular Inspections Check the seals regularly for signs of wear and damage. Look for leaks, cracks, or any deformation, as these could signal that a replacement is needed.

2. Proper Installation Ensure that seals are installed correctly. An improper installation can lead to premature failure. Follow manufacturer instructions and, if in doubt, consult a professional mechanic.

3. Use the Right Lubricant Always use the recommended grease for your specific application. The wrong type of grease can degrade the seal material and compromise its sealing ability.

4. Replace As Needed Don’t wait for a seal to fail completely. If you notice any signs of wear, replace the seal promptly to prevent further damage to the bearings.

5. Environment Awareness Be conscious of the operating environment for your vehicle. If the vehicle is frequently exposed to harsh conditions, it may require more frequent seal checks and maintenance.

Conclusion

Wheel hub grease seals are a small yet crucial part of vehicle and machinery operation, contributing significantly to the longevity and performance of wheel bearings. Understanding their function, types, and maintenance practices can help prevent costly repairs and ensure smooth operation. Regular checks and timely replacements will maximize the lifespan of these vital components, keeping you safe on the road.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories