Dec . 21, 2024 18:17 Back to list

Choosing the Right Wheel Bearing Grease and Seal for Optimal Performance

Understanding Wheel Bearing Grease Seals Importance, Types, and Maintenance

Wheel bearing grease seals are vital components in the automotive industry, playing a critical role in the performance and longevity of vehicles. These seals serve to protect wheel bearings from contaminants like dirt, water, and debris, while also retaining the necessary grease to ensure smooth operation. This article delves into the importance of wheel bearing grease seals, the different types available, and best practices for maintenance.

Importance of Wheel Bearing Grease Seals

Wheel bearing grease seals are essential for several reasons. First and foremost, they help maintain the integrity of the wheel bearings by preventing contaminants from entering the bearing assembly. Contaminated bearings can lead to premature wear, decreased performance, and ultimately, failure of the wheel bearings, which could result in detrimental consequences on the road.

Moreover, these seals help retain the grease that lubricates the bearings. Proper lubrication is crucial, as it reduces friction and heat generated during the vehicle's operation. Without adequate lubrication, bearings can overheat, leading to a breakdown of the grease and increased wear. Therefore, the role of the grease seal is not just protective; it is also essential for maintaining optimal operating conditions for the wheel assembly.

Types of Wheel Bearing Grease Seals

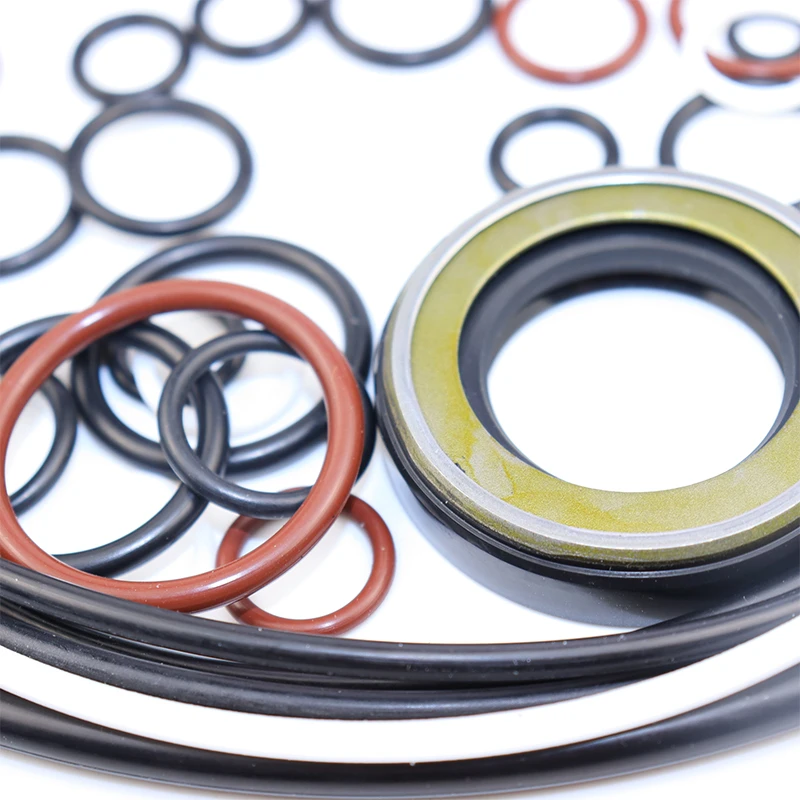

There are several types of wheel bearing grease seals, each designed for specific applications and environments. The most common types include

1. Rubber Seals These are widely used due to their excellent flexibility and sealing capabilities. Rubber seals are typically more affordable and can efficiently keep out dirt and moisture. However, they may not be suitable for extreme temperatures or heavy-duty applications.

2. Lip Seals Lip seals have a special design that includes a flexible lip that makes contact with the shaft. This design creates a superior seal, making it highly effective at preventing leakage and the entry of contaminants. Lip seals are common in performance vehicles and heavy machinery.

3. Metal Seals Metal seals are often used in applications that require a higher degree of durability and resistance to harsh conditions. These seals can withstand higher temperatures and pressures, making them ideal for heavy-duty trucks and industrial vehicles.

wheel bearing grease seal

4. Composite Seals Combining different materials, composite seals offer enhanced performance characteristics. They provide a robust sealing solution while also accommodating varying temperatures and pressures.

Maintenance of Wheel Bearing Grease Seals

Proper maintenance of wheel bearing grease seals is essential for ensuring their longevity and effectiveness. Here are a few tips to keep in mind

1. Regular Inspection Regularly inspect the grease seals for signs of wear or damage. Check for cracks, distortions, or any signs of leaking grease. Early detection of issues can prevent more significant problems down the line.

2. Proper Installation Ensuring that seals are correctly installed is critical. Misalignment or improper fitting can lead to premature failure. Follow manufacturer guidelines for installation procedures to maintain optimal performance.

3. Use Quality Grease The type of grease used in conjunction with the seals significantly impacts their lifespan. Always opt for high-quality wheel bearing grease that meets or exceeds the manufacturer's specifications.

4. Environmental Considerations Be mindful of the conditions in which your vehicle operates. Frequent exposure to moisture, dirt, or extreme temperatures may necessitate more frequent inspections and maintenance of the grease seals.

5. Professional Assistance If unsure about the condition of your wheel bearing grease seals or how to maintain them, seeking professional assistance is always a wise approach. Technicians can provide valuable insights and necessary repairs to keep your vehicle running smoothly.

Conclusion

In summary, wheel bearing grease seals are integral to the overall health and performance of a vehicle's wheel assembly. Understanding their importance, recognizing the various types available, and adhering to maintenance best practices can significantly improve the lifespan of both the seals and the wheel bearings they protect. Investing time and effort into proper care can yield substantial dividends in terms of vehicle reliability and safety on the road.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories