Aug . 21, 2024 16:06 Back to list

Understanding the Importance of Seals in Hydraulic Cylinder Performance and Durability

Understanding Hydraulic Cylinder Seals Anatomy and Importance

Hydraulic cylinders are critical components in a variety of machinery and industrial applications, enabling the conversion of fluid power into mechanical force. At the heart of their functionality lies the hydraulic cylinder seals. These seals play a vital role in maintaining the efficiency and reliability of hydraulic systems, and understanding their design, materials, and maintenance can significantly impact operational performance.

What Are Hydraulic Cylinder Seals?

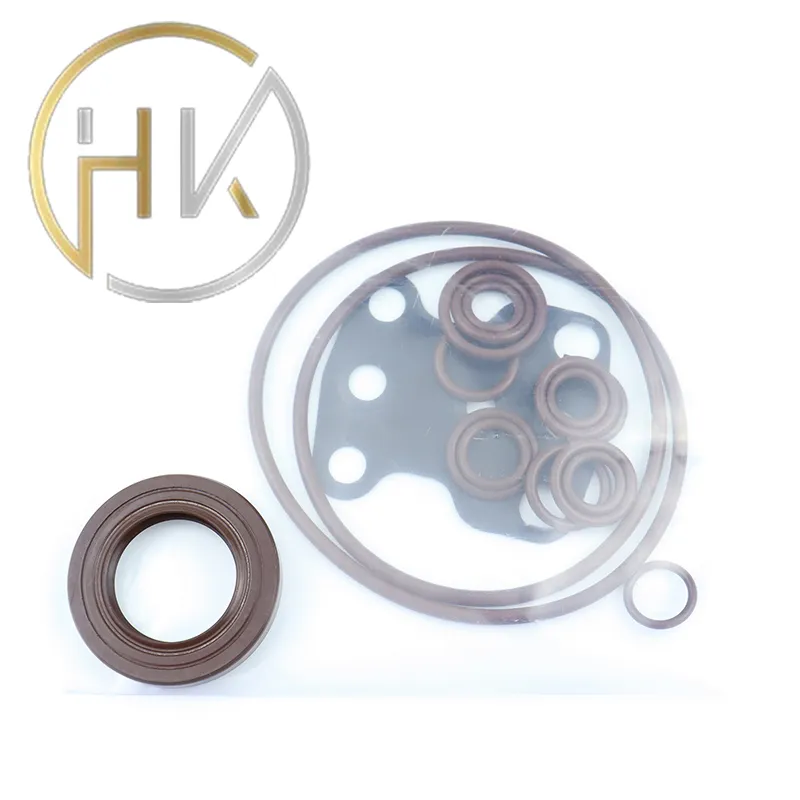

Hydraulic cylinder seals are devices used to contain hydraulic fluids within the cylinder while preventing leaks and contamination. They act as barriers between the fluid and the atmosphere, ensuring that the hydraulic pressure generated by the fluid is effectively utilized to perform work. The primary types of seals found in hydraulic cylinders include rod seals, piston seals, and end-cap seals, each serving a specific function in the system.

1. Rod Seals Located in the cylinder head, rod seals prevent fluid from leaking past the rod as it extends and retracts. They ensure that the hydraulic cylinder operates efficiently and maintain pressure within the system. A well-designed rod seal minimizes friction, reducing wear and tear on both the seal and the hydraulic rod.

2. Piston Seals These seals sit within the cylinder body and are responsible for isolating fluid on either side of the piston. Piston seals are crucial for maintaining the cylinder's performance under varying pressures and load conditions. Their design must accommodate the dynamic movement of the piston while ensuring a tight seal to prevent fluid loss.

3. End-Cap Seals These seals are positioned at the ends of the hydraulic cylinder and serve to close off the cylinder unit, preventing fluid from escaping. They also help to protect the internal components from dirt and contaminants that could impair functionality.

Materials Matter

The materials used in the construction of hydraulic cylinder seals are critical to their performance and longevity. Common materials include nitrile rubber (NBR), polyurethane (PU), and polytetrafluoroethylene (PTFE). Each material has unique properties that make it suitable for different applications

hydraulic cylinder seals

- Nitrile Rubber (NBR) Known for its excellent oil resistance and mechanical properties, NBR is widely used in low to medium-pressure applications.

- Polyurethane (PU) This material is favored for its durability and abrasion resistance, making it ideal for high-pressure environments.

- PTFE Often used in applications requiring a wide temperature range and low friction, PTFE seals are particularly effective in environments where chemical resistance is necessary.

Selecting the right material for hydraulic seals is essential to ensure they withstand the operating conditions, such as temperature fluctuations and exposure to various fluids.

Maintenance and Care

Proper maintenance of hydraulic cylinder seals is paramount to extend their service life and ensure optimal performance. Regular inspection is needed to identify any signs of wear, such as cracks, swelling, or discoloration. Implementing a routine maintenance schedule that includes checking fluid levels, replacing damaged seals, and ensuring clean fluid entry can prevent costly downtime and hydraulic system failures.

Additionally, training personnel on the importance of seal integrity can contribute to improved performance. Employees should be educated about the proper handling of hydraulic components to minimize the risk of introducing contaminants that could compromise seal effectiveness.

Conclusion

Hydraulic cylinder seals are indispensable in the realm of hydraulic systems, ensuring operational efficiency and reliability. Understanding their types, materials, and maintenance practices can lead to better performance and longer service life of hydraulic equipment. By paying attention to these critical components, industries can enhance productivity, reduce maintenance costs, and extend the lifespan of their machinery.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories