Aug . 08, 2024 04:15 Back to list

Understanding the Importance of Gearbox Oil Seals for Optimal Vehicle Performance and Longevity

Understanding Gearbox Oil Seals Importance and Maintenance

In the realm of machinery and vehicles, the gearbox is a critical component that plays a vital role in the overall performance and efficiency of the system. Central to the functioning of the gearbox is the oil seal, a small yet indispensable part that ensures the smooth operation of gears and minimizes the risk of damage. This article delves into the significance of gearbox oil seals, their functions, types, and maintenance practices.

What is a Gearbox Oil Seal?

A gearbox oil seal is designed to prevent lubricant leakage from the gearbox while simultaneously keeping out dirt, dust, and moisture. Typically made from durable materials like rubber or synthetic compounds, these seals retain the gearbox oil essential for lubricating the moving parts within the transmission system. Without effective seals, gearboxes would be prone to wear, reduced efficiency, and ultimately, catastrophic failure.

The Importance of Gearbox Oil Seals

1. Prevention of Oil Leakage The primary function of a gearbox oil seal is to contain the lubricating oil within the gearbox. This not only prevents potential environmental pollution but also ensures that the gearbox has a sufficient oil level for proper lubrication.

2. Protection Against Contamination Gearboxes operate in various environments, often exposed to dirt, debris, and moisture. Oil seals serve as a barrier, protecting the internal mechanisms from contaminants that could cause wear and reduce the lifespan of the gears.

3. Enhancement of Performance By maintaining proper lubrication, oil seals help in reducing friction between moving parts. This leads to better fuel efficiency, smoother operation, and improved overall performance of the vehicle or machinery.

4. Cost-Effectiveness Regular maintenance and replacement of gearbox oil seals can save considerable costs in the long run. By preventing oil leaks and contamination, companies can avoid expensive repairs and downtime associated with gearbox failures.

Types of Gearbox Oil Seals

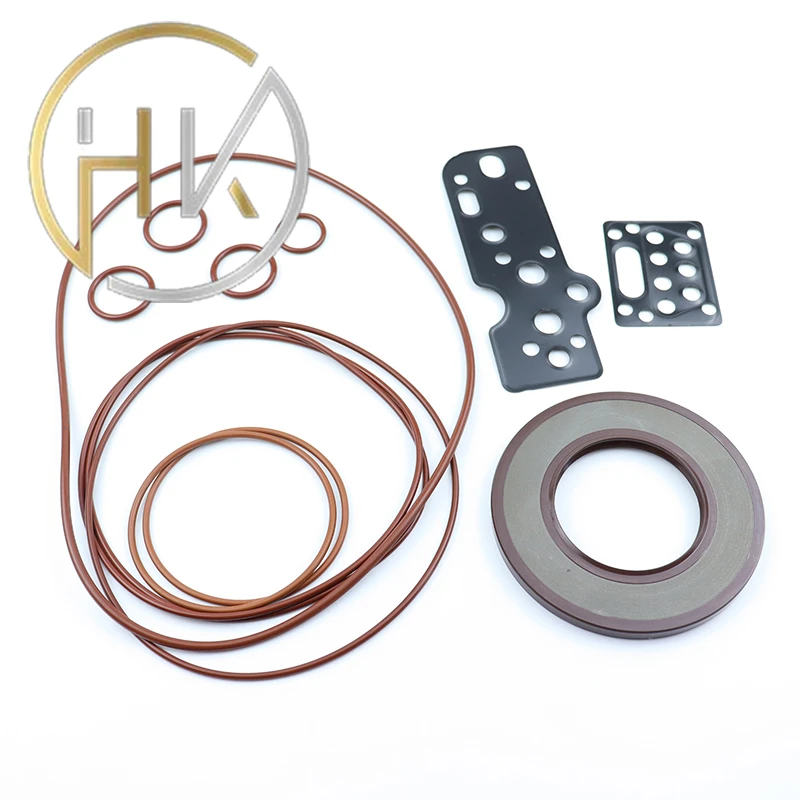

gear box oil seal

Gearbox oil seals come in various designs and configurations, tailored to meet specific operational needs. The most common types include

- Lip Seals These have a flexible lip that extends into the gearbox, providing a tight seal against the rotating shaft. They are widely used due to their effective sealing and ability to handle various lubrication types. - O-Ring Seals Simple yet effective, O-rings are circular rings used to create a sealing mechanism when compressed between two surfaces. They are often employed in static applications and can be used in conjunction with other sealing methods.

- Double-lip Seals These seals feature two sealing lips, enhancing the barrier against oil loss and external contaminants. They are particularly useful in environments where maximum protection is needed.

Maintenance of Gearbox Oil Seals

To ensure the longevity and effectiveness of gearbox oil seals, regular maintenance is essential. Here are some best practices

1. Routine Inspections Regularly check for signs of oil leaks around the gearbox and inspect the condition of the oil seals. Look for cracks, wear, or deformation that may suggest the need for replacement.

2. Proper Installation When replacing oil seals, ensure that they are installed correctly and evenly. Improper installation can lead to premature failure and leaks.

3. Use of Quality Materials Opt for high-quality seals that are specifically designed for your gearbox type. Cheaper alternatives may not provide the same level of protection and durability.

4. Timely Replacement Establish a routine for replacing oil seals based on the manufacturer's recommendations or when noticeable wear is observed. This proactive approach can prevent major failures.

In conclusion, gearbox oil seals play a crucial role in maintaining the functionality and longevity of gearbox systems. By understanding their function, types, and maintenance, users can ensure that their machinery or vehicles operate efficiently for years to come. Whether for industrial applications or personal vehicles, paying attention to these small yet vital components can lead to significant benefits in performance and cost savings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories