Jul . 27, 2024 15:13 Back to list

Understanding the Importance and Functionality of Wiper Seals in Mechanical Systems

Understanding Wiper Seals Importance and Functionality

Wiper seals are essential components in a wide array of machinery and equipment, primarily serving to prevent leakage of fluids, dirt, and other contaminants. Found in hydraulic cylinders, automotive systems, and industrial machinery, these seals play a crucial role in ensuring optimal performance and longevity of mechanical components. This article delves into the importance, functionality, and types of wiper seals.

The Role of Wiper Seals

Wiper seals are designed to keep contaminants out of moving parts, particularly in hydraulic and pneumatic systems. They are typically positioned at the outer edge of a cylinder, acting as a barrier to dirt and debris while simultaneously maintaining the internal lubrication needed for smooth operation. By preventing contaminants from entering critical areas, wiper seals help reduce wear and tear on machinery, thereby extending the life of components and minimizing maintenance costs.

In automotive applications, wiper seals are particularly important in preventing fluid leaks in systems like brakes and power steering. If a seal fails, it could lead to decreased performance and safety issues. For example, leaking brake fluid can result in a significant drop in braking efficiency, creating a hazardous situation for drivers.

How Wiper Seals Work

Wiper seals function through a combination of design and material properties. Typically made from elastomers like nitrile rubber, polyurethane, or silicone, these materials provide flexibility and resilience. The shape of the wiper seal is crucial; it usually features a lip that contacts the surface of a rod or piston. This contact helps to scrape away contaminants while allowing the seal to retain its shape under pressure.

When the piston moves, the wiper seal flexes, creating a seal that prevents contaminants from entering the internal assembly. The design is engineered so that it accommodates some degree of movement while maintaining effective sealing. Proper installation and alignment are essential to ensure that the wiper seal performs optimally, as any misalignment can lead to premature failure.

Types of Wiper Seals

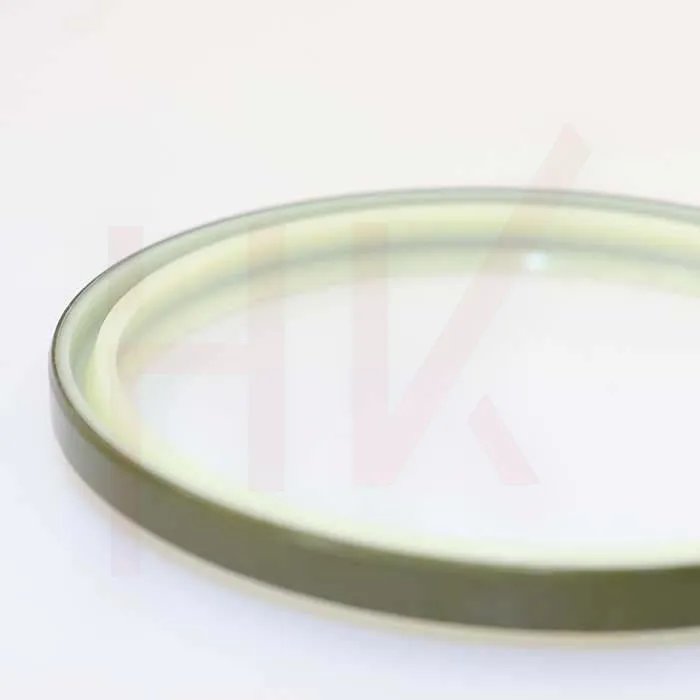

wiper seal

There are various types of wiper seals, each tailored to specific applications. The most common types include

1. Lip Seals These seals have a flexible lip that wipes the surface effectively, ideal for keeping dust and dirt at bay.

2. Rod Seals Often used in hydraulic cylinders, rod seals prevent leakage from the rod and are essential in maintaining pressure.

3. Piston Seals Typically used in hydraulic and pneumatic applications, these seals prevent fluid from leaking past the piston when under pressure.

4. V-Seals These are simple, yet effective, seals that provide excellent protection against dirt and moisture, often utilized in rotating shafts.

5. Wiper Seals with Metal Reinforcement Designed for heavy-duty applications, these seals incorporate metal to enhance durability and performance under extreme conditions.

Conclusion

Wiper seals are a fundamental yet often overlooked aspect of mechanical systems. Their role in preventing contamination, maintaining lubrication, and reducing maintenance needs cannot be overstated. By understanding the functionality and various types of wiper seals, engineers and maintenance professionals can make informed decisions regarding their selection and application. Investing in high-quality wiper seals will not only enhance the performance of machinery and equipment but also contribute to safety and efficiency in numerous industrial and automotive applications. As technology advances, the materials and designs of wiper seals will continue to evolve, promising better performance and reliability in the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories