Aug . 13, 2024 12:16 Back to list

Understanding High Pressure Rotary Shaft Seals for Enhanced Performance in Industrial Applications

High Pressure Rotary Shaft Seals Enhancing Reliability and Performance

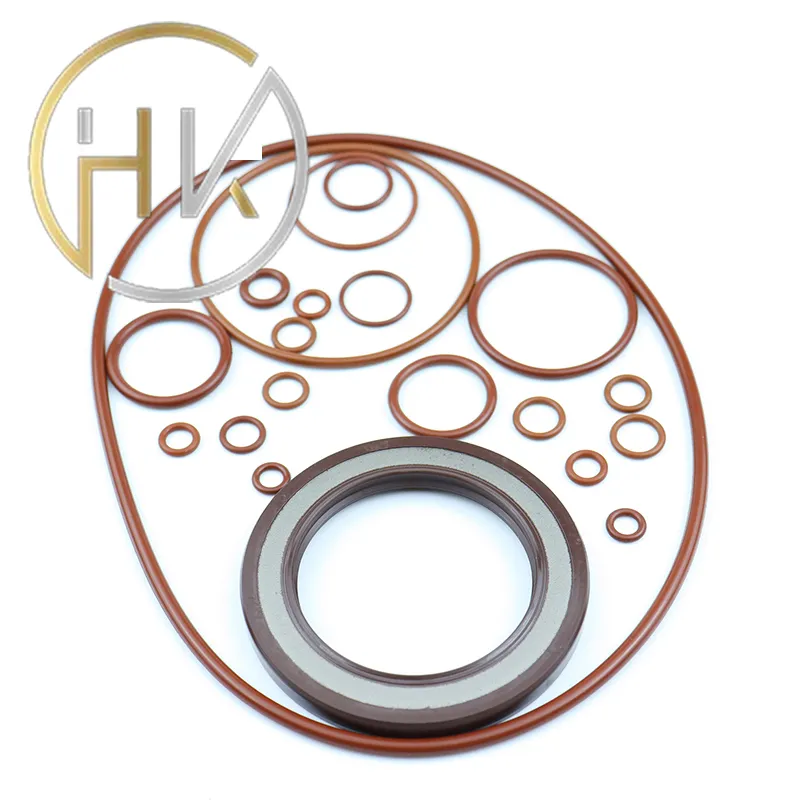

In various industrial applications, the need for reliable sealing solutions is paramount, especially in high-pressure environments. High pressure rotary shaft seals play a critical role in preventing leaks, maintaining pressure, and ensuring low friction at the interface between rotating and stationary components. These seals are integral to numerous systems, including hydraulic pumps, motors, and compressors, where they safeguard against fluid loss and contamination while enhancing overall efficiency.

Rotary shaft seals, also known as oil seals or lip seals, are engineered to function effectively in dynamic applications where they are subjected to rotational movement along with axial and radial forces. High pressure environments present unique challenges due to increased stress on sealing materials, potential for fluid or gas ingress, and varying temperatures that can affect seal performance. Therefore, selecting the right materials and design for high pressure applications is crucial.

Material Selection

The materials used in high pressure rotary shaft seals are a key factor in their effectiveness. Commonly utilized materials include nitrile rubber (NBR), fluorocarbon (FKM), polyurethane (PU), and silicone. Each material has distinctive properties that make it suitable for different applications.

1. Nitrile Rubber (NBR) This material is widely used due to its excellent oil resistance and durability at moderate temperatures. NBR seals are ideal for applications involving petroleum-based fluids, making them a popular choice in automotive and industrial machinery.

2. Fluorocarbon (FKM) Known for its superior chemical resistance and ability to withstand high temperatures, FKM is ideal for applications involving aggressive chemicals and extreme conditions. This material can maintain sealing effectiveness in environments exceeding 200 °C.

3. Polyurethane (PU) PU is recognized for its mechanical strength and resilience. It offers good wear resistance and elasticity, making it suitable for high-speed applications where friction is a concern.

4. Silicone Often used in applications that require resistance to extreme temperatures, silicone seals are compatible with a broad range of fluids and exhibit excellent flexibility.

high pressure rotary shaft seal

Design Considerations

In addition to material selection, the design of high pressure rotary shaft seals is crucial. Engineers must consider seal geometry, lip design, and installation conditions to optimize performance. The seal lip, which is the active sealing component, can be engineered with various profiles, such as single or double lips, to provide enhanced sealing capabilities.

Moreover, the radial compression and preload applied to the seal during installation play a significant role in its performance. Properly designed seals maintain a suitable contact pressure against the shaft, ensuring that leaks are minimized without generating excessive friction that could lead to wear.

Applications and Benefits

High pressure rotary shaft seals are widely employed in applications such as hydraulic systems, automotive engines, aerospace components, and industrial machinery. Their primary benefits include

- Leak Prevention Effective sealing eliminates the risk of fluid loss, which is crucial in maintaining operational efficiency and safety.

- Contamination Protection These seals prevent external contaminants such as dirt and moisture from entering sensitive machinery components, thereby extending service life.

- Energy Efficiency By minimizing friction and maintaining pressure, high pressure rotary shaft seals contribute to better energy efficiency in rotating systems.

In conclusion, high pressure rotary shaft seals are essential components in modern machinery that demand reliability and performance in challenging environments. Their effectiveness hinges on appropriate material selection and thoughtful design, making them vital for industries ranging from manufacturing to aerospace. As technology evolves, the continued development of advanced sealing solutions will further enhance the functionality and reliability of high-pressure systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories