Nov . 09, 2024 18:24 Back to list

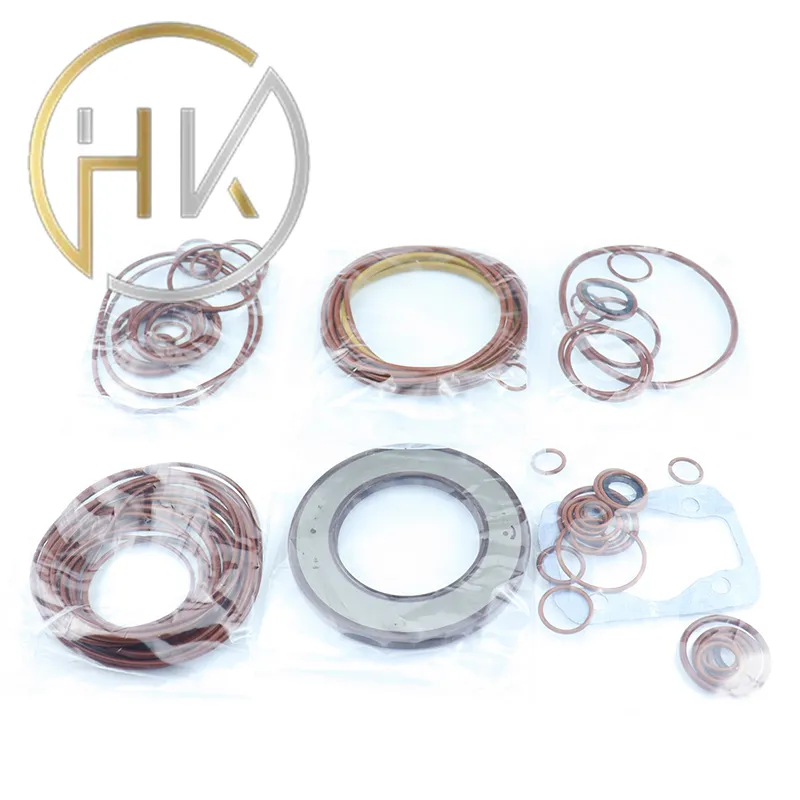

Tilt Cylinder Seal Kit for Enhanced Performance and Durability in Hydraulic Systems

Understanding Tilt Cylinder Seal Kits An Essential Component for Hydraulic Systems

Hydraulic systems are pivotal in various industrial applications, ranging from construction machinery to agricultural equipment. At the heart of these systems lies the tilt cylinder, a component that plays a critical role in controlling movements and positions. To ensure the optimal performance of tilt cylinders, one must pay close attention to the quality and maintenance of seal kits. In this article, we will delve into the significance of tilt cylinder seal kits, their components, and the factors to consider when selecting the right one.

What is a Tilt Cylinder?

A tilt cylinder is a hydraulic actuator that enables the tilting motion of an implement or structure. Commonly found in excavators, forklifts, and other heavy machinery, these cylinders convert hydraulic fluid pressure into mechanical motion. They facilitate the desired angles and positions required for various operations, enhancing the versatility and efficiency of the equipment.

The Role of Seal Kits

Seal kits are essential for the operation of tilt cylinders. They prevent hydraulic fluid from leaking out of the cylinder while simultaneously keeping contaminants, such as dirt and debris, from entering. This sealing capability is crucial for maintaining pressure within the hydraulic system and ensuring smooth functionality. A well-sealed cylinder minimizes wear and tear on internal components, thereby extending the lifespan of the equipment.

Components of Tilt Cylinder Seal Kits

Tilt cylinder seal kits typically consist of several types of seals designed to handle different functions

1. Rod Seals These seals are placed on the rod side of the cylinder. They prevent fluid from leaking past the rod as it moves in and out of the cylinder. A good rod seal not only prevents leakage but also reduces friction to improve overall efficiency.

2. Piston Seals Installed on the piston, these seals are responsible for creating a tight barrier that prevents fluid from escaping the cylinder’s chamber. They play a crucial role in maintaining the hydraulic pressure necessary for the cylinder's operation.

3. Wipers Positioned at the entrance of the cylinder, wipers are designed to remove mud, dirt, and debris from the rod before it enters the cylinder. This protection is vital as it helps maintain the integrity of the internal seals by keeping them free from contaminants that can cause premature wear.

tilt cylinder seal kit

4. Backup Rings These are used alongside primary seals to provide additional support and flexibility. They prevent the primary seal from extruding out of the groove under high-pressure conditions.

Factors to Consider When Selecting Seal Kits

Choosing the right tilt cylinder seal kit is crucial for ensuring operational efficiency. Here are some key factors to consider

1. Compatibility Always check the compatibility of the seal kit with your specific tilt cylinder model. Seal kits are designed to fit particular cylinder dimensions and styles; using an incompatible kit could lead to leaks and equipment failure.

2. Material Quality The materials used in seal kits can significantly affect their performance and longevity. Look for kits made from high-quality elastomers, such as polyurethane or nitrile rubber, which offer excellent resistance to temperature fluctuations and hydraulic fluids.

3. Hydraulic Fluid Compatibility Ensure that the seal materials are compatible with the type of hydraulic fluid used in your system. Different fluids can have varying effects on seal integrity, including swelling or degradation.

4. Operating Environment Consider the operating conditions of the equipment. If the tilt cylinder is subject to extreme temperatures, high pressures, or exposure to harsh chemicals, selecting a seal kit designed for those conditions is crucial.

5. Manufacturer Reputation Opt for seal kits from reputable manufacturers known for their quality control and testing. Investing in trusted products can save time and costs associated with frequent replacements and repairs.

Conclusion

Tilt cylinder seal kits are a small yet vital component of hydraulic systems that can significantly impact the performance and longevity of machinery. By understanding the components and considerations involved in selecting these kits, operators and maintenance personnel can ensure their equipment remains efficient and reliable. Proper maintenance and timely replacement of seal kits will not only prevent costly downtime but also extend the service life of hydraulic systems, ultimately leading to better productivity and profitability in various industrial applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories