Dec . 16, 2024 00:56 Back to list

skeleton oil seal

Understanding Skeleton Oil Seals Function, Applications, and Benefits

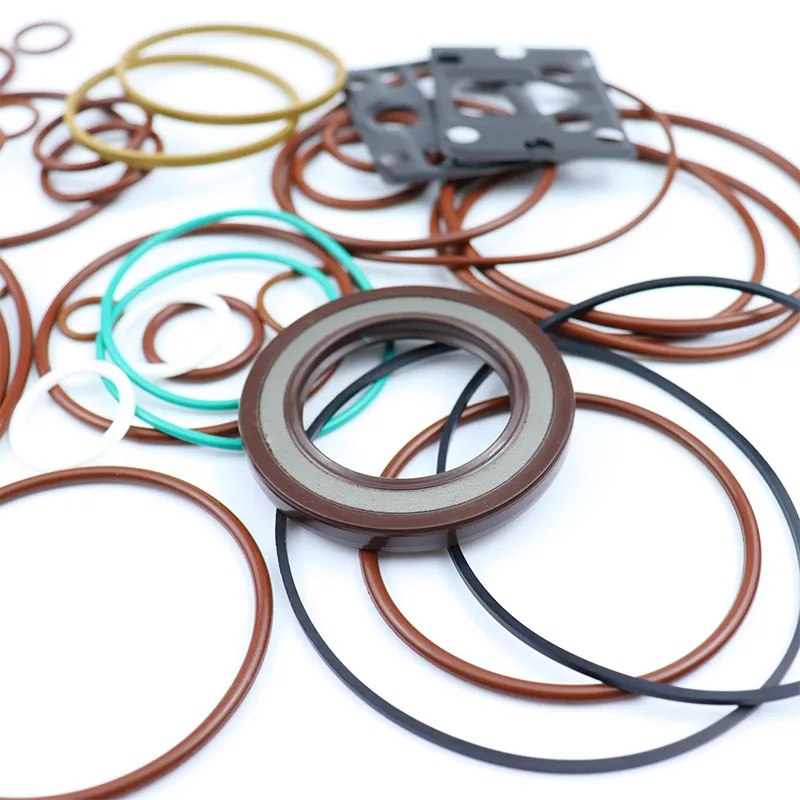

Skeleton oil seals, also known as skeleton seals or elastomeric seals, are critical components in various machinery and automotive applications. They play a significant role in preventing the leakage of lubricants, oils, and fluids, while also protecting systems from contaminants. This article provides an overview of skeleton oil seals, including their design, function, applications, and benefits.

Design and Structure

The design of a skeleton oil seal typically involves a metal casing, an elastomeric sealing lip, and sometimes a dust lip. The metal structure provides rigidity and ensures that the seal maintains its shape under pressure. The elastomeric portion, usually made from materials such as rubber, silicone, or polyurethane, creates a tight seal against a rotating shaft or between stationary components. The skeleton part refers to the support structure that enhances durability and resistance to various operational conditions.

Skeleton oil seals come in different sizes and configurations, tailored to meet specific industry requirements. The design can also incorporate features such as anti-extrusion rings or auxiliary lips to improve performance in high-pressure applications.

Functionality

The primary function of skeleton oil seals is to prevent fluid leakage from equipment while simultaneously blocking dirt, dust, and other contaminants from entering the sealed area

. This functionality is vital for maintaining the integrity and efficiency of machines, as any leakage can lead to inadequate lubrication, increased friction, overheating, and eventual failure of the components.The sealing lip of the skeleton oil seal flexibly conforms to the surface of the rotating shaft, creating a dynamic seal that adapts to various operating conditions. This design allows the seal to maintain effective sealing capabilities even when subjected to pressure fluctuations, temperature changes, and shaft misalignment.

Applications

skeleton oil seal

Skeleton oil seals are widely used across various industries, including automotive, aerospace, industrial machinery, and consumer appliances. In the automotive sector, they are commonly found in engines, transmissions, and differentials. For instance, these seals prevent oil from leaking out of engine components and protect the internal parts from external contaminants, thus prolonging the engine's lifespan.

In industrial applications, skeleton oil seals are utilized in hydraulic systems, motors, pumps, and compressors. Their ability to withstand harsh operating conditions makes them suitable for high-pressure and high-temperature environments.

Benefits

One of the primary benefits of using skeleton oil seals is their reliability. The robust design ensures long service life and minimal maintenance requirements. Furthermore, they contribute to overall system efficiency by minimizing fluid loss, which can otherwise lead to increased operational costs.

Another significant advantage is their versatility. Skeleton oil seals can be used in a wide range of applications and can be custom-engineered to fit specific requirements. This adaptability makes them a preferred choice for many engineers and designers.

Moreover, by preventing contamination ingress, these seals help maintain the cleanliness of lubricants and fluids, which is essential for the optimal performance of machinery. This protection against dirt and dust minimizes wear and tear on critical components, enhancing the overall longevity and reliability of the equipment.

Conclusion

In conclusion, skeleton oil seals are indispensable components in many mechanical applications. Their unique design, combined with versatile functionality, makes them essential for fluid retention and contamination control. Whether in automotive engines or industrial machinery, skeleton oil seals ensure reliability and efficiency, thereby playing a critical role in the performance and longevity of machinery. With ongoing advancements in materials and design technology, the future of skeleton oil seals remains promising, continuing to meet the evolving needs of various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories