Sep . 23, 2024 03:50 Back to list

single acting piston seal

Understanding Single Acting Piston Seals Function, Design, and Applications

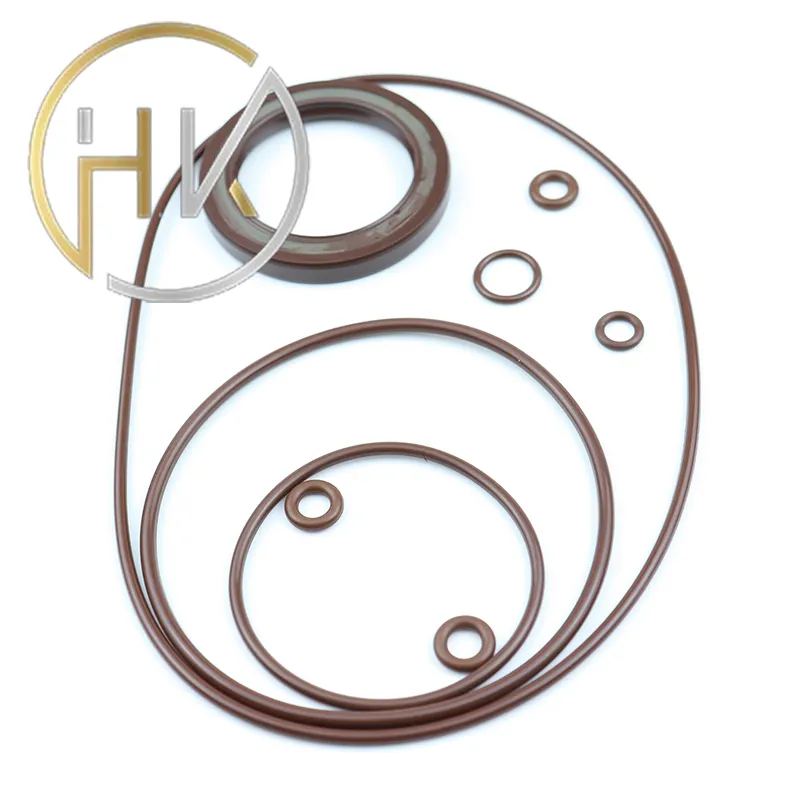

Single acting piston seals are essential components used in various hydraulic and pneumatic applications. Their primary function is to prevent fluid leakage, ensuring efficient operation and extending the service life of machinery. This article explores the design, operation, and applications of single acting piston seals.

What is a Single Acting Piston Seal?

A single acting piston seal is designed to seal in one direction, meaning it effectively manages pressure from one side while allowing minimal intrusion from the other. Typically used in hydraulic cylinders, these seals are crucial for applications where fluid needs to be contained in one specific area while allowing for motion in a linear direction.

Key Characteristics

Single acting piston seals are characterized by their specific geometric designs, which enhance sealing performance. They are often made from elastomeric materials such as polyurethane, nitrile, or silicone, ensuring a balance between flexibility and durability. The design typically includes a lip that faces the pressurized side and a back-up ring to prevent extrusion in high-pressure environments.

The effectiveness of a seal primarily depends on its ability to withstand pressure fluctuations and environmental factors such as temperature and exposure to chemicals. As such, choosing the right material is crucial for optimal performance.

The Working Principle

single acting piston seal

In operation, when the piston moves in the direction of the loaded side, the seal compresses against the cylinder wall, creating a tight fit that prevents fluid from escaping. As the piston retracts, the seal should ideally relax, allowing for smooth movement without causing drag. This dynamic interaction is what allows hydraulic systems to operate efficiently without compromising on power.

Applications

Single acting piston seals find applications across various industries. They are prevalently used in

1. Hydraulic Cylinders In machinery such as excavators and forklifts, single acting seals provide the necessary sealing for lifting and lowering mechanisms. 2. Automotive Systems Many automotive braking systems utilize single acting piston seals to ensure the hydraulic pressure is maintained while allowing the braking force to be applied effectively.

3. Industrial Equipment Various manufacturing processes, particularly those involving heavy machinery, depend on these seals for the reliable operation of fluid power systems.

4. Aerospace Applications The performance and safety standards in aerospace applications necessitate reliable sealing solutions, making single acting piston seals integral to flight control systems and landing gear.

Conclusion

Single acting piston seals play a pivotal role in the performance and reliability of fluid systems. Their ability to contain pressure in one direction ensures efficient operation, making them indispensable across a multitude of industries. As technology advances, the design and materials used for these seals continue to evolve, leading to improved performance and longevity. By understanding the significance and functionality of single acting piston seals, industries can enhance productivity and reduce the risks associated with fluid leaks and system failures.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories