Nov . 20, 2024 00:50 Back to list

single acting piston seal

Understanding Single Acting Piston Seals Function, Design, and Applications

Single acting piston seals are vital components in many hydraulic and pneumatic systems, employed to prevent fluid leakage and ensure operational efficiency. These seals primarily allow movement in one direction while containing pressures from that direction. Though they might seem simple at first glance, their design, materials, and application are nuanced and critical to the overall functionality of a device or machine.

Functionality of Single Acting Piston Seals

A single acting piston seal operates by creating a tight seal between the piston and the cylinder wall, preventing the working fluid from escaping and maintaining pressure within the system. This function is particularly important in applications where the hydraulic or pneumatic action is reliant on maintaining a specific pressure to achieve desired outcomes, such as in hydraulic cylinders, hydraulic pumps, and automotive applications.

The seal is designed to accommodate movement while maintaining integrity against the fluid pressure. This design allows the piston to move in one direction—usually, the force is applied in the forward movement stroke, while the retraction is achieved through another mechanism, often involving a spring or gravity.

Design Considerations

The design of single acting piston seals must account for several key factors

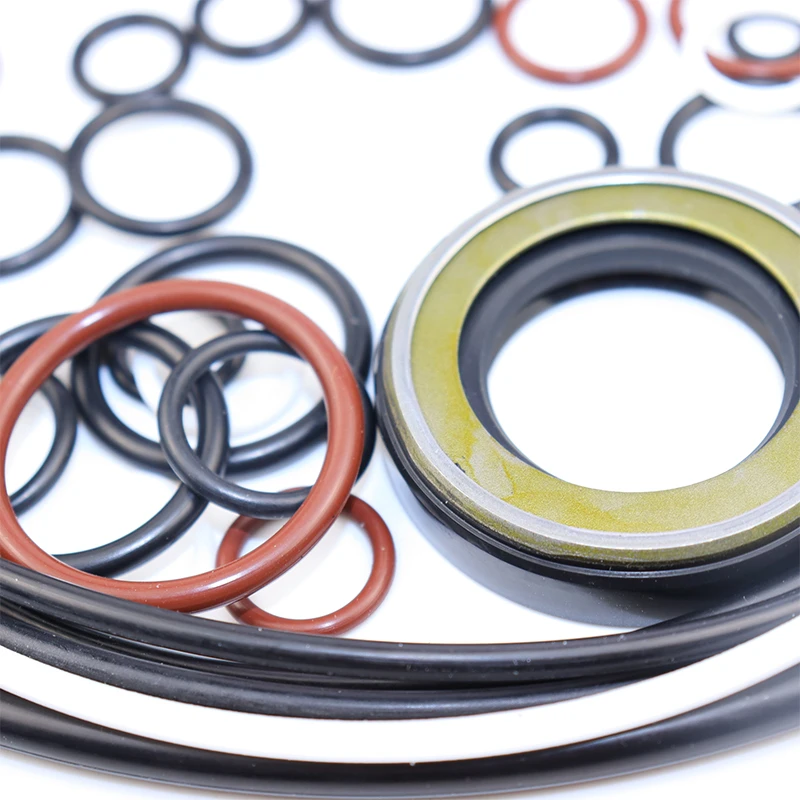

1. Material Selection The materials used for piston seals vary significantly based on the specific application. Common materials include elastomers (such as Nitrile or Viton), PTFE, and polyurethane. Each material offers different properties, including temperature resistance, chemical compatibility, and wear resistance. Proper selection ensures that the seal can sustain the operating conditions without failure.

2. Seal Profile The shape of the seal plays an essential role in its performance. Common profiles include O-rings, U-cups, and V-rings. The choice of profile depends on factors such as the stroke length, pressure, and the fluid being sealed. For example, U-cup seals are often preferred for their ability to handle both low and high-pressure systems efficiently.

single acting piston seal

3. Clearance and Tolerance Adequate clearance must be maintained between the piston and the cylinder wall. Too tight a fit can lead to excessive friction and premature wear, while too loose a fit can compromise sealing performance. Engineers must carefully calculate the optimal tolerance during the design phase to balance these considerations.

Applications

The applications of single acting piston seals are diverse, encompassing several industries

- Hydraulic Systems In hydraulic applications, single acting piston seals find usage in hydraulic cylinders for machinery, lifting equipment, and automotive applications, ensuring that hydraulic fluid does not leak out during operation.

- Pneumatic Systems These seals are also essential in pneumatic systems, where air pressure is utilized for various applications such as actuators and compressors. The seals maintain the pressure required for the functionality of the system.

- Industrial Machinery In the manufacturing sector, single acting piston seals are critical components in automated machinery that require precise movement control. The reliability of these seals ensures that operations remain seamless and efficient.

- Aerospace and Automotive In the aerospace sector, these seals can be found in landing gear systems and actuation systems where high reliability is crucial. Similarly, in the automotive industry, they are used in braking systems, power steering, and other critical components that depend on a sealed environment.

Conclusion

Single acting piston seals are integral to the proper functioning of various hydraulic and pneumatic systems, ensuring that pressure is maintained effectively while preventing fluid leakage. The right choice of materials, seal design, and precise engineering play a crucial role in their performance. Understanding the functionality, design considerations, and applications of these seals helps in selecting the appropriate sealing solution for specific industrial needs, ultimately contributing to the efficiency and reliability of machinery and equipment. As technology advances, the development of more resilient materials and innovative designs will continue to enhance the performance and longevity of single acting piston seals in various applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories