Sep . 30, 2024 17:28 Back to list

Understanding the Functionality and Importance of Shaft Wipers in Machinery Maintenance

Understanding Shaft Wipers Their Importance and Functionality

Shaft wipers play a crucial role in the functionality and longevity of various machinery and equipment. These components are designed to seal and protect the moving parts of shafts, effectively preventing contaminants from entering critical areas. In industries ranging from manufacturing to automotive, shaft wipers are essential for maintaining the performance and reliability of machines. In this article, we will explore the significance, types, and applications of shaft wipers, shedding light on why they deserve more attention in engineering and maintenance discussions.

What are Shaft Wipers?

Shaft wipers are sealing components that fit around rotating or sliding shafts. Their primary function is to wipe off contaminants, such as dust, dirt, grease, and water, that may occur during the operation of machinery. By keeping these foreign particles at bay, shaft wipers help to maintain the integrity of bearings, seals, and other sensitive components that could be damaged by wear and tear or contamination.

Importance of Shaft Wipers

1. Contamination Prevention One of the primary functions of shaft wipers is to prevent contaminants from entering critical areas of machinery. This is particularly important in hydraulic systems, where oil and lubricants are essential for smooth operation. Contaminants can lead to increased friction, reduced efficiency, and eventual system failures.

2. Extended Equipment Life By protecting sensitive components, shaft wipers contribute to the overall longevity of machinery. Regularly maintaining and replacing these wipers can result in significant cost savings over time, as it reduces the need for repairs and replacements of more expensive components.

3. Enhanced Performance A clean system operates more efficiently. Shaft wipers ensure that lubricants remain clean and effective, which helps maintain optimal operating conditions. This is especially vital in high-speed applications where friction and heat can cause severe damage.

Types of Shaft Wipers

Shaft wipers come in various designs and materials to suit different applications

. Here are some common types1. Plastic Wipers Lightweight and cost-effective, plastic wipers are ideal for applications that do not experience extreme temperatures or pressures. They are often used in lighter machinery and consumer products.

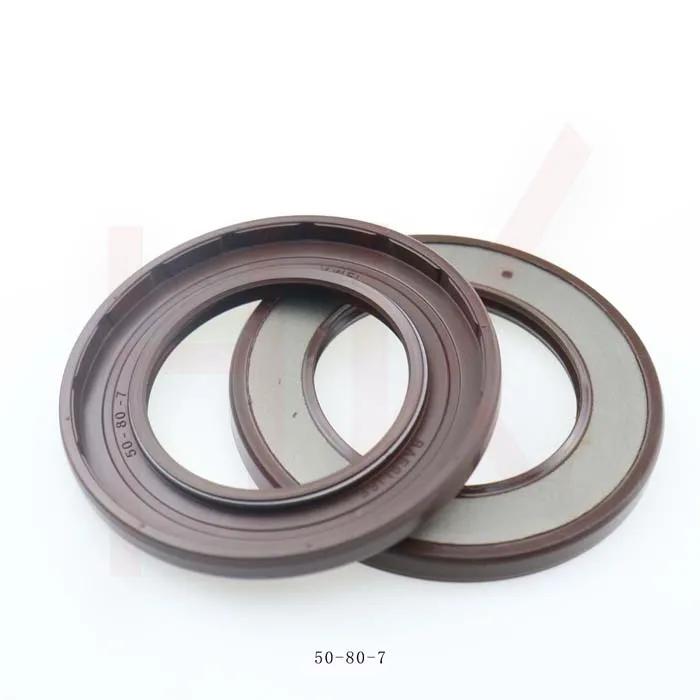

shaft wipers

2. Rubber Wipers These offer greater flexibility and durability, making them suitable for medium to heavy-duty applications. Rubber wipers can withstand a range of temperatures and are often used in automotive and industrial machinery.

3. Metallic Wipers For heavy-duty applications, metallic wipers provide strength and resistance to harsh environments. They are often combined with seals and gaskets to provide a robust sealing solution.

4. Custom-made Wipers In specialized applications, manufacturers may opt for custom-designed shaft wipers. These are tailored to fit specific dimensions and performance requirements, ensuring optimal protection and efficiency.

Applications of Shaft Wipers

Shaft wipers are employed in a wide range of industries, including

1. Automotive In vehicles, shaft wipers are used in steering systems, brake mechanisms, and engine components. They help maintain the integrity of lubricants and protect against dust and debris.

2. Manufacturing In machine tools and production equipment, shaft wipers ensure that components remain clean and operational. This is particularly important in CNC machines and other automated systems, where precision is paramount.

3. Aerospace The aerospace industry often uses shaft wipers to protect critical components in aircraft systems. These wipers help maintain the reliability of machinery exposed to extreme environmental conditions.

4. Robotics In robotic systems, where precision and reliability are essential, shaft wipers play a key role in maintaining the operability of moving parts and sensors.

Conclusion

Shaft wipers are more than just simple components; they are vital elements that contribute to the efficiency, reliability, and longevity of various machinery and systems. By understanding their importance and selecting the appropriate types, engineers and maintenance professionals can significantly enhance the performance of their equipment. Whether in automotive manufacturing, aerospace, or robotics, recognizing the value of shaft wipers can lead to better maintenance practices and ultimately improve operational efficiency. As technology continues to evolve, the design and functionality of shaft wipers will undoubtedly advance, further solidifying their place in the world of engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories