Nov . 13, 2024 06:16 Back to list

shaft seal wheel hub

Understanding Shaft Seal Wheel Hubs Importance and Function

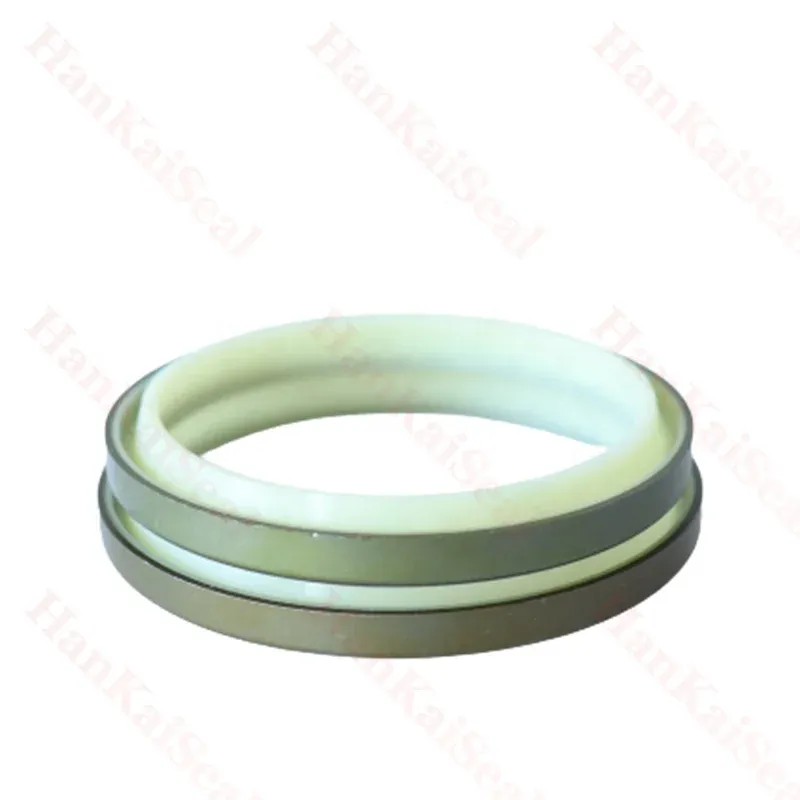

Shaft seal wheel hubs are crucial components in various machinery, particularly in automotive and industrial applications. These components play a vital role in maintaining the integrity of the system by preventing the leakage of fluids, such as lubricants or coolant, from the wheel assembly. The efficiency and reliability of vehicles and machines heavily depend on the proper functioning of these seals.

At the core of a shaft seal wheel hub is the concept of sealing. When a shaft spins within a housing, there exists a need to contain fluids around the rotating part to minimize wear, prevent contamination, and maintain optimal operating conditions. A shaft seal effectively creates a barrier, which is essential for achieving durability and performance.

Manufactured from various materials, such as rubber, silicone, or thermoplastic elastomers, shaft seals can withstand different temperatures, pressures, and environmental conditions. The choice of material often depends on the application and the specific environment in which the wheel hub operates. For example, in heavy machinery exposed to harsh conditions, a high-performance seal designed for resilience will be necessary to extend equipment life, reduce maintenance costs, and improve reliability.

shaft seal wheel hub

One of the most significant benefits of utilizing shaft seal wheel hubs is their ability to prevent fluid loss

. In automotive applications, a failing seal can lead to leaks that might compromise the vehicle's performance, leading to overheating or mechanical failures. These seals are designed to retain lubricants that are essential for reducing friction between moving parts, which is critical for the overall functionality of the vehicle.Moreover, the design of shaft seals can vary widely. Some designs feature additional components, such as springs or dust shields, to enhance their effectiveness. The presence of these added features helps to keep contaminants out and ensures that the seal remains tight even when under variable loads and temperatures.

Installation and maintenance of shaft seal wheel hubs are also critical aspects. Proper installation ensures that the seal fits snugly and functions as intended. Regular maintenance checks can help identify wear or damage early, thus preventing costly breakdowns and repairs. In many cases, replacing an old or damaged seal can significantly improve performance and extend the lifespan of the equipment.

In conclusion, shaft seal wheel hubs are integral to the effective functioning of machinery and vehicles. Their ability to prevent leaks, protect internal components, and support operational efficiency cannot be overstated. As industries continue to evolve, the demand for reliable sealing solutions will only increase, further highlighting the importance of these components in modern technology. Quality materials, proper installation, and regular maintenance will ensure that shaft seals perform optimally, safeguarding the machinery and ensuring smooth operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories