Dec . 11, 2024 19:28 Back to list

seals and wipers

Seals and Wipers An Overlooked but Essential Component of Machinery

In the world of machinery, seals and wipers play an indispensable role, often overshadowed by the more glamorous components such as engines or gearboxes. However, these humble elements are critical for ensuring the longevity and efficiency of various mechanical systems. From vehicles to industrial equipment, the effectiveness of seals and wipers can greatly influence the performance and reliability of machinery.

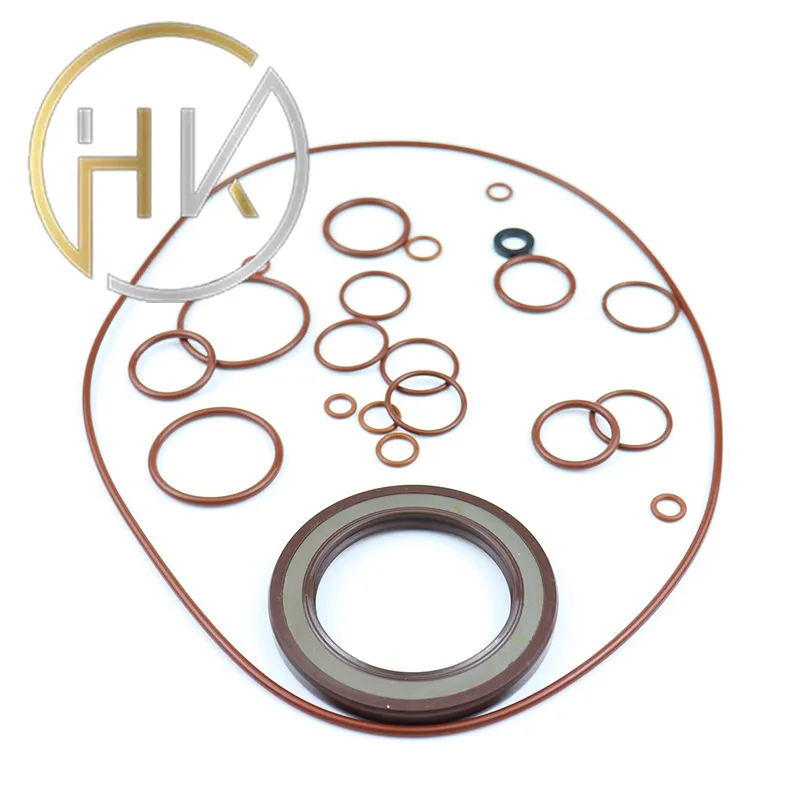

Seals are designed to prevent the leakage of fluids and to protect against contaminants. They come in various forms, including static seals, which are used in applications where there is no movement between the surfaces, and dynamic seals, which accommodate moving parts, such as shafts in rotary applications. The materials used for seals vary widely, ranging from rubber and silicone to more advanced materials like PTFE (polytetrafluoroethylene) and polyurethane. Each material offers unique properties, including temperature and chemical resistance, enabling engineers to select the appropriate seal for specific applications.

One prominent example of seals in action can be observed in automotive applications. Car engines are complex systems where numerous seals prevent oil, coolant, and other fluids from leaking. Inadequate sealing can lead to significant issues, such as engine overheating, loss of lubrication, and ultimately, engine failure. The importance of seals is further heightened in electric vehicles, which often require specialized seals to protect sensitive electronic components from moisture and debris.

Wipers, on the other hand, serve a different yet equally crucial purpose. Primarily associated with improving visibility, especially in automotive contexts, wipers remove water, dirt, and other debris from glass surfaces. They contribute not only to safety but also to aesthetic appeal. However, wipers are not limited to vehicles; they also find their place in various industrial applications, where they clean surfaces and prevent contaminants from compromising the functionality of machinery.

seals and wipers

The design of wipers is equally important as that of seals. Effective wipers must possess the right balance of flexibility and rigidity to adequately conform to glass surfaces while being durable enough to withstand wear and tear caused by constant use. Materials such as rubber or specially formulated thermoplastics are common choices due to their resilience and ability to maintain effective contact with surfaces.

The interplay between seals and wipers is often seen in hydraulic and pneumatic systems, where both components work in tandem to ensure smooth operation. In hydraulic systems, seals prevent fluid leaks, while wipers keep the surfaces clean, allowing seals to function optimally. For instance, hydraulic cylinders often employ wipers to clean the shaft as it moves in and out of the cylinder, reducing the risk of contaminants entering the system, which could lead to premature seal failure.

Moreover, advancements in technology are continuously enhancing the performance of seals and wipers. The introduction of new materials, such as nanomaterials and advanced polymers, allows for improved resistance to extreme conditions, resulting in longer lifespans and better reliability. Additionally, automated manufacturing processes ensure precision in the production of these components, further enhancing their effectiveness.

Maintenance is another critical aspect of ensuring the longevity of seals and wipers. Regular inspection and replacement of worn-out components can help prevent costly breakdowns and repairs in machinery. For instance, a small leak in a seal might not seem significant initially, but it can result in extensive damage if left unchecked.

In conclusion, while seals and wipers may not be the most visible components of machinery, their functionality is vital for the seamless operation of various systems. As technology continues to evolve, so too will the materials and designs of these components, ensuring they meet the demands of modern applications. Recognizing the importance of seals and wipers not only enhances our understanding of machinery but also emphasizes the need for proper maintenance and care in keeping our equipment running smoothly. A little attention to these often-overlooked parts can save time, money, and resources, proving that in machinery, even the smallest components can have a significant impact.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories