Dec . 04, 2024 17:01 Back to list

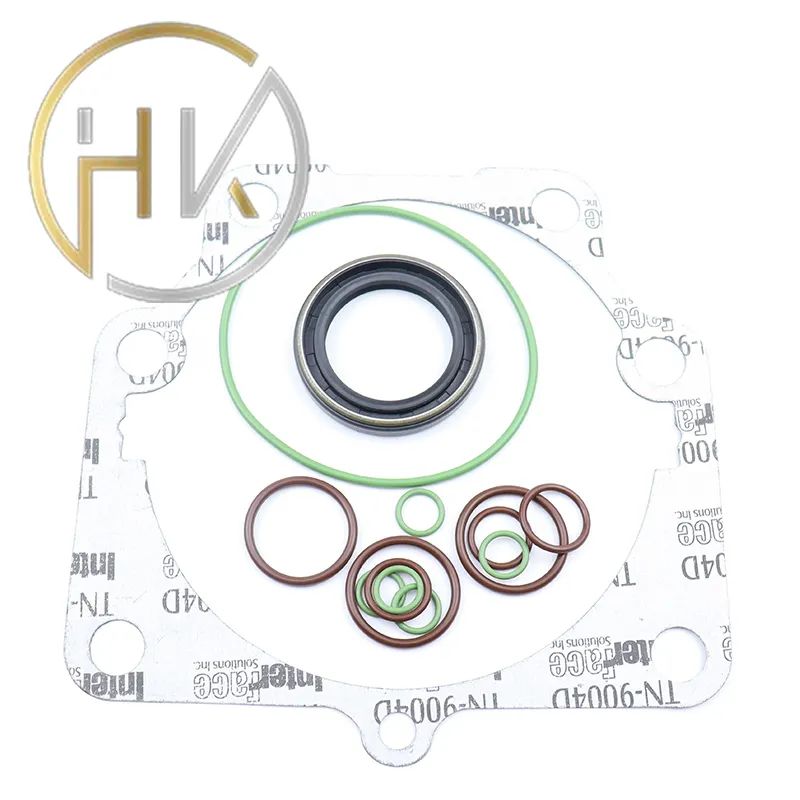

seal kit pump

Sealing Solutions The Importance of Seal Kit Pumps in Modern Machinery

In today’s fast-paced industrial environment, the efficiency and reliability of machinery are paramount. Central to this reliability are seal kit pumps, which play a critical role in various applications, from construction equipment to manufacturing processes. Understanding the significance of seal kits in pumping systems is essential for anyone involved in the maintenance and operation of machinery.

What is a Seal Kit Pump?

A seal kit pump refers to a pumping system equipped with a seal kit that prevents fluid leaks and maintains pressure within the system. Seal kits typically include a variety of components such as O-rings, gaskets, seals, and other related hardware designed to fit specific pump models. These components are engineered to withstand high pressure and temperature variations, making them crucial for the longevity of the pump and the machinery it serves.

The Role of Seal Kits in Pump Performance

The primary function of a seal kit is to maintain the integrity of the system by preventing leaks. In a pump, leaks can lead to a significant decrease in efficiency, potentially resulting in equipment failure and increased operational costs. Moreover, leaks can pose safety risks, especially in applications involving hazardous or corrosive fluids. By ensuring a tight seal, the seal kit helps to facilitate optimal performance, maintain pressure, and protect the environment from harmful spills.

Selection of Seal Kits

seal kit pump

Choosing the right seal kit is vital for achieving the best performance from a pump. Factors such as the type of fluid being pumped, operating temperature, pressure ratings, and the specific application all influence the selection process. Materials used in seal kits also vary—for instance, rubber, PTFE, and polyurethane are common choices, each offering unique benefits depending on the operational conditions. Selecting inappropriate components can lead to premature wear and catastrophic failure, making it critical to consult with manufacturers or industry experts when choosing seal kits.

Maintenance and Replacement

Regular maintenance of seal kits is essential to ensure the continued effectiveness of pumps. Over time, seals and gaskets can wear due to exposure to fluids, pressure fluctuations, and environmental factors. Routine inspections can help detect early signs of wear or damage, allowing timely replacements before they lead to larger issues. Replacing seal kits at the recommended intervals can dramatically extend the life of pumps and machinery, resulting in lower maintenance costs and reduced downtime.

Technological Advancements

In recent years, advancements in technology have led to the development of more durable and efficient seal kits. Innovations such as advanced materials and design improvements help enhance the performance and lifespan of seals. Manufacturers are continuously researching ways to produce seal kits that can withstand extreme conditions, thereby reducing the frequency of replacements and the associated costs. Moreover, the integration of smart monitoring technologies offers predictive maintenance capabilities, alerting operators about potential failures before they happen.

Conclusion

Seal kit pumps are crucial components in the machinery that drives modern industry. They ensure efficient operation by preventing leaks, maintaining pressure, and enhancing the overall reliability of pumping systems. Understanding the importance of selecting the right seal kit, performing regular maintenance, and embracing technological advancements is vital for any organization looking to improve its operational efficiency. As industries continue to evolve, the role of seal kit pumps will undoubtedly remain indispensable in providing reliable and safe machinery operations. By investing in quality seal kits and ongoing maintenance practices, businesses can safeguard their equipment and contribute to a sustainable operational environment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories