Nov . 24, 2024 05:40 Back to list

Hydraulic Pump Solutions for Seal Kits and Maintenance Needs in Industrial Applications

Exploring Seal Kit Hydraulic Pumps An Essential Component for Fluid Power Systems

Hydraulic pumps play an essential role in fluid power systems, transferring energy through the movement of hydraulic fluid. Among the various components of a hydraulic pump, the seal kit is crucial in ensuring efficient operation and longevity. In this article, we will delve into the importance of seal kits in hydraulic pumps, their components, and maintenance practices to keep these systems running smoothly.

Understanding Hydraulic Pumps

Hydraulic pumps convert mechanical energy into hydraulic energy by moving fluid through a hydraulic system. They are commonly used in various applications, including construction equipment, automotive systems, and industrial machinery. The efficiency of these pumps largely depends on their internal components, among which the seal kit is a key player.

The Importance of Seal Kits

Seal kits in hydraulic pumps are designed to prevent fluid leaks, which can lead to significant losses in performance and potential damage to the system. A well-functioning seal kit ensures that the hydraulic fluid remains contained within the pump and prevents contaminants from entering the system, which can result in operational failures.

Hydraulic pumps encompass two main types gear pumps and piston pumps. Each type relies on its specific seal arrangements to maintain operational integrity. For instance, gear pumps typically utilize O-rings and gaskets, while piston pumps may employ more complex seals to handle the higher pressure and varying movement dynamics.

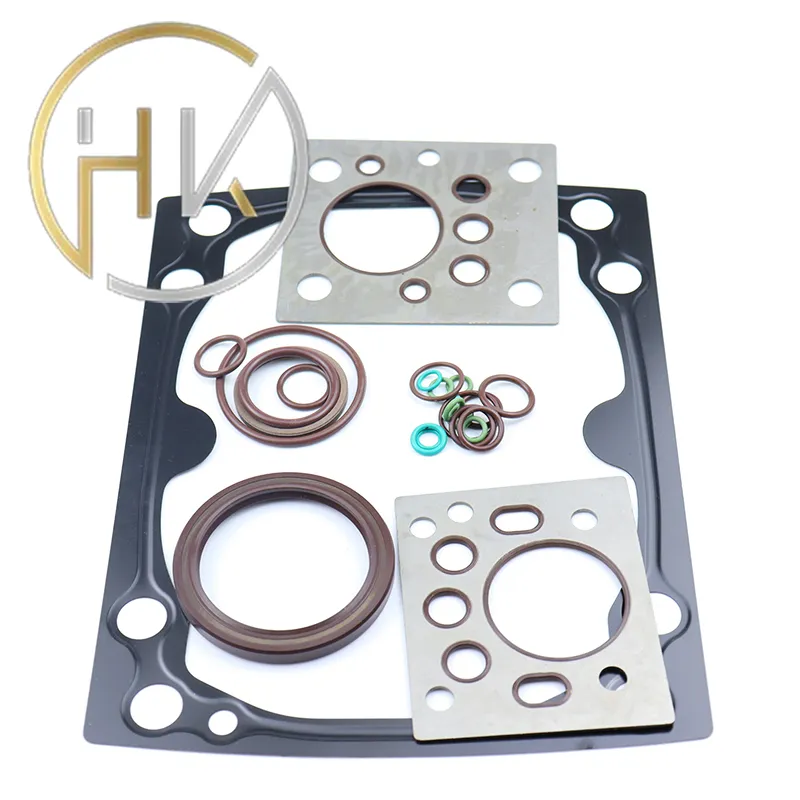

Components of a Seal Kit

A typical seal kit contains several critical components designed to create a reliable seal within the hydraulic pump. These components typically include

1. O-rings These circular seals are commonly used in hydraulic systems to prevent leaks at connection points.

3. Back-up rings Used in conjunction with O-rings, back-up rings increase the pressure handling capabilities by preventing the O-ring from extruding under high pressure.

seal kit hydraulic pump

4. Wipers Wipers or scrapers are used to keep contaminants away from the sealing area, maintaining the seal’s integrity.

5. Rod seals These are designed to prevent hydraulic fluid from leaking along the shaft of the hydraulic cylinder, ensuring that the system remains pressurized.

Maintenance of Seal Kits

Regular maintenance of hydraulic pumps and their seal kits is essential for preventing breakdowns and ensuring optimal performance. Here are some key maintenance practices

1. Routine Inspection Regularly inspect seals for wear, tear, and any signs of leaks. Early detection can prevent more severe damage.

2. Fluid Quality Ensure that the hydraulic fluid is clean and at the correct viscosity. Contaminated or degraded fluid can lead to premature wear of seals and components.

3. Pressure Monitoring Keep track of system pressures. Abnormal pressure readings can indicate seal failure or other issues within the pump.

4. Environment Control Store hydraulic pumps in environments free of contaminants. Dust, dirt, and moisture can compromise the seal's effectiveness.

5. Replacement Protocol Follow manufacturer recommendations for replacing seal kits. After a certain period or usage, the seals may lose their effectiveness, necessitating replacement.

Conclusion

Seal kits are indispensable components in hydraulic pumps that ensure system integrity and efficiency. Understanding their significance and proper maintenance can prolong the life of hydraulic systems and enhance performance. By paying attention to the components of the seal kits and adhering to maintenance best practices, operators can avoid costly downtimes and repairs, ensuring their hydraulic machinery operates smoothly and efficiently. Whether in the construction sector or manufacturing, investing in quality seal kits and maintaining them properly will lead to improved operational efficiency and reliability in fluid power systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories