Dec . 11, 2024 10:07 Back to list

hydraulic seal kits for reliable performance and maintenance solutions

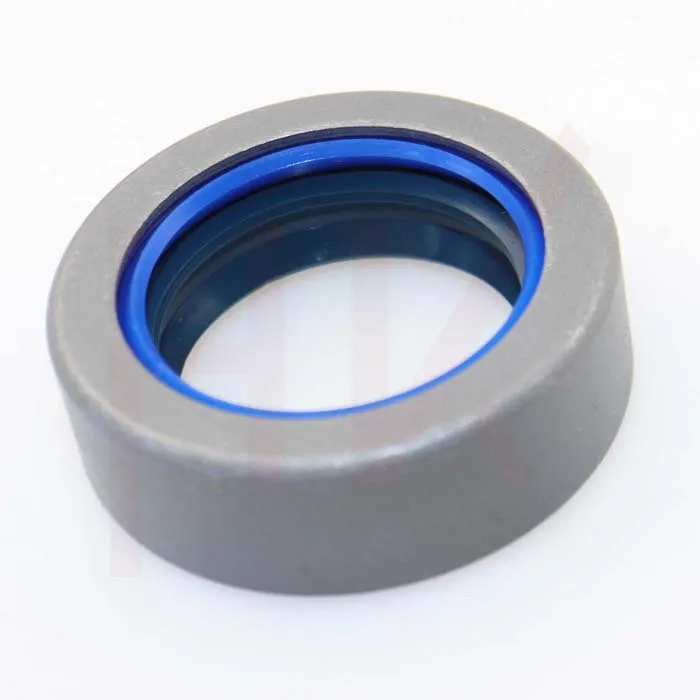

Understanding Seal Kit Hydraulic Systems Importance and Applications

Seal kits are essential components in hydraulic systems, serving as the backbone that ensures proper and efficient operation. A seal kit in a hydraulic system typically includes various seals, O-rings, gaskets, and other related components specifically designed to prevent fluid leaks and protect the system from contamination. Understanding the intricacies of seal kits, particularly for hydraulic systems, is crucial for maintaining equipment reliability and longevity.

The Functionality of Seal Kits in Hydraulic Systems

Hydraulic systems operate by transmitting power through pressurized fluids, commonly oil. These systems are found in a wide range of applications, including construction machinery, automotive systems, and industrial equipment. The seals within a seal kit play a pivotal role in containing the hydraulic fluid, ensuring that it flows efficiently through cylinders, pumps, and valves.

The primary functions of seal kits in hydraulic systems include

1. Leak Prevention One of the most critical roles of seal kits is to prevent hydraulic fluid from leaking out of the system. Any leak not only leads to a loss of pressure but can also result in environmental contamination and increased operational costs.

2. Contamination Control Seal kits act as barriers to keep dirt, dust, and other contaminants from entering the hydraulic system. Contamination can cause wear, corrosion, and eventual failure of hydraulic components, leading to costly repairs and downtime.

3. Pressure Maintenance The seals in a hydraulic system help maintain pressure, ensuring that the system operates efficiently. Proper sealing allows for the effective transfer of force, enabling machinery to perform tasks such as lifting, pushing, or driving.

4. Temperature Regulation Hydraulic fluids operate within specific temperature ranges. Seal kits are designed to withstand variations in temperature, ensuring that the seals maintain their integrity and function even under extreme conditions.

Types of Seals in Hydraulic Seal Kits

seal kit hydraulic

Hydraulic seal kits contain various types of seals, each designed for specific applications and environments. Some common types include

- O-Rings These circular seals are versatile and used in various applications to create a tight seal in static and dynamic systems. They come in different materials and sizes, depending on the fluid and temperature conditions.

- U-Cups Typically used for piston seals, U-cups provide excellent sealing performance and reduced friction. They are particularly suitable for reciprocating motion applications.

- Back-up Rings These components are often used in conjunction with O-rings to prevent extrusion at high pressures. They provide additional support and enhance the longevity of the seal.

- Gaskets Used where two surfaces meet, gaskets help create a seal by filling the gaps to prevent leaks. They are crucial in applications where pressure and temperature fluctuations are prevalent.

Importance of Choosing the Right Seal Kit

Selecting the appropriate seal kit for a hydraulic system is vital. Factors to consider include the type of hydraulic fluid, operating temperature, pressure levels, and the specific application environment. Using the wrong type of seal can result in premature failure, leading to costly repairs and unscheduled downtime.

Manufacturers usually provide guidelines on the compatible seal kits for their hydraulic components. It's essential for maintenance personnel and engineers to adhere to these recommendations to ensure optimal performance and reliability of the hydraulic systems.

Conclusion

In conclusion, seal kits play a fundamental role in the functionality of hydraulic systems. Their ability to prevent leaks, control contamination, maintain pressure, and withstand fluctuating temperatures makes them critical components in various industries. Understanding the types of seals involved and the significance of choosing the right seal kit ensures that hydraulic systems operate efficiently and effectively. Regular inspection and maintenance of seal kits can significantly enhance the lifespan of hydraulic equipment, contributing to improved performance and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories