Feb . 17, 2025 13:20 Back to list

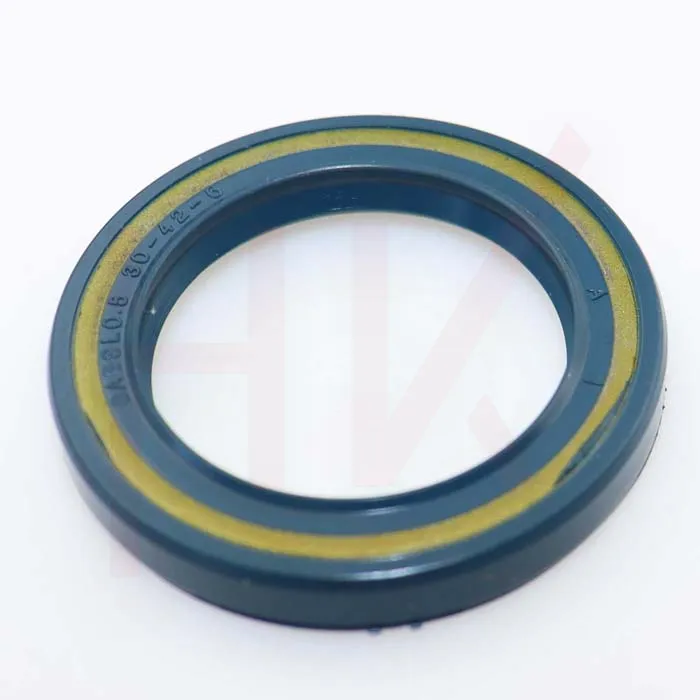

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Moreover, the authoritativeness in this arena stems from recognizing when a seal kit replacement is necessary. Symptoms such as visible oil leaks, reduced lifting speeds, or erratic lowering of loads are indicators of a compromised seal. Addressing these symptoms promptly with the correct seal kit not only ensures uninterrupted operations but also prolongs the machine's lifespan. This preemptive approach underscores an authoritative understanding of the machinery, preventing costly repairs and operational disruptions. Building trustworthiness in selecting and utilizing seal kits involves sourcing from reputable manufacturers and suppliers known for their quality and reliability. Purchasing genuine and certified seal kits helps prevent substandard repairs that might lead to further complications. Furthermore, consulting with technicians who have substantial experience with pallet jack maintenance ensures that the installation is performed correctly, thereby mitigating risks associated with improper handling or installation. Experience demonstrates that consistent maintenance and timely replacement using high-quality seal kits translate to significant cost savings over time. The operational efficiency gained from these best practices invariably leads to smoother logistics operations, enhancing overall productivity. An insightful investment in quality seal kits and their upkeep not only assures the functionality of pallet jacks but also contributes to a safer, more reliable workplace environment. In conclusion, while seal kits for pallet jacks may seem like a minor component within the larger logistics operation, their importance cannot be overstated. Expertise in this domain directly affects not only the equipment’s performance but also the financial and operational dynamics of the business. Embodying a blend of experience, professionalism, and meticulous attention to detail in sourcing and applying seal kits is foundational to maintaining a robust and efficient warehousing environment. By prioritizing these aspects, businesses can achieve a seamless workflow, bolstered by the reliability and precision of well-maintained pallet jacks.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories