Oct . 01, 2024 03:15 Back to list

Exploring the Features and Benefits of Seal Kit Cylinders for Enhanced Performance

Understanding Seal Kit Cylinders Importance and Applications

In the world of hydraulic and pneumatic systems, understanding the intricacies of seal kit cylinders is crucial for both the efficiency and longevity of machinery. Seal kits are essential components that ensure the proper functioning of cylinders by preventing fluid leakage, maintaining pressure, and protecting against contamination. This article will delve into the specifics of seal kit cylinders, their applications, and the importance of selecting the right seal kits.

What is a Seal Kit Cylinder?

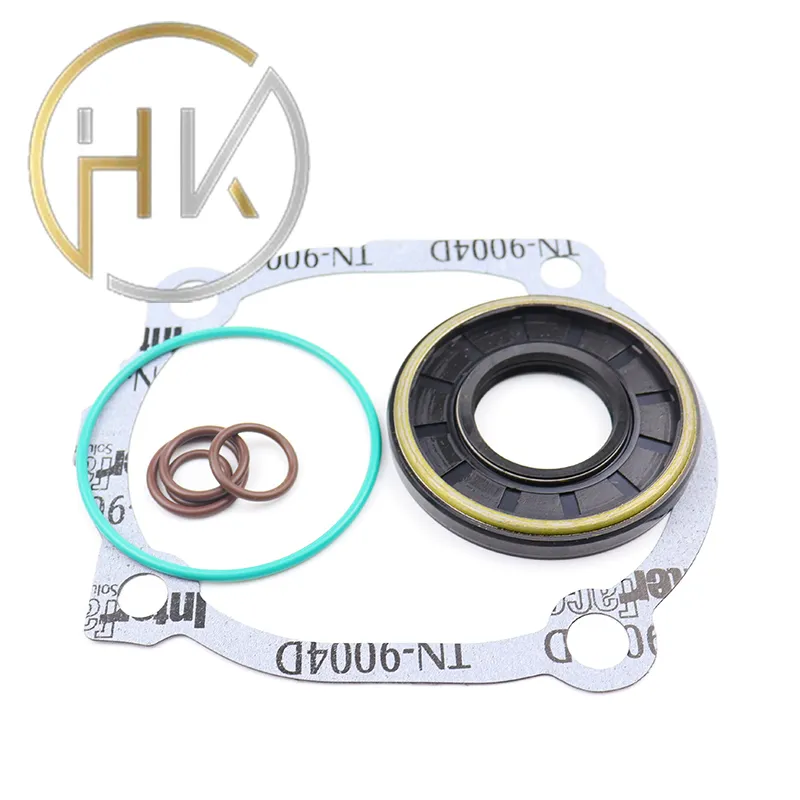

A seal kit cylinder refers to a hydraulic or pneumatic cylinder that includes a set of seals—rubber, o-rings, gaskets, and other components designed to contain hydraulic fluid or air within the cylinder. These seals are vital in preventing leaks, maintaining the pressure necessary for efficient operation, and protecting the internal components of the cylinder against wear and tear from external elements.

Components of Seal Kits

Seal kits typically consist of several types of seals

1. O-Rings These circular rings provide a sealing surface for static and dynamic applications. They can withstand various pressures and are often used in both hydraulic and pneumatic cylinders. 2. Rod Seals Designed to prevent fluid leakage around the moving shaft of the cylinder. They play a crucial role in maintaining pressure within the cylinder while allowing for smooth movement.

3. Piston Seals These seals are positioned between the piston and the cylinder wall, preventing leakage of fluids and maintaining the necessary pressure for effective operation.

4. Back-Up Rings Used in conjunction with seals to provide additional support and prevent extrusion, which can lead to premature failure of the seals.

5. Gaskets These are used between components to provide a surface that prevents leaks when two surfaces meet.

Importance of Seal Kits

The importance of high-quality seal kits cannot be overstated. Faulty or worn-out seals can lead to a variety of problems, including

seal kit cylinder

- Fluid Leakage This not only causes a loss of operational efficiency but can also lead to environmental hazards. - Increased Wear Ineffective seals can allow contaminants to enter the cylinder, leading to wear and potential system failures. - Reduced Efficiency Loss of pressure can cause the entire system to work harder, wasting energy and increasing operational costs.

By investing in quality seal kits, operators ensure the reliability of their machinery and reduce maintenance costs over time. Proper seals not only enhance the performance of hydraulic and pneumatic systems but also extend the overall lifespan of the equipment.

Applications of Seal Kit Cylinders

Seal kit cylinders are utilized in various industries, including

- Manufacturing Hydraulic cylinders are essential in manufacturing processes, including metal forming, material handling, and assembly. - Construction Heavy machinery such as excavators, bulldozers, and cranes rely on hydraulic cylinders for movement and lifting operations. - Automotive In automotive production, hydraulic systems are crucial for various applications, from assembly lines to testing equipment. - Aerospace Seal kit cylinders are critical in aerospace applications where precision and reliability are paramount.

Selecting the Right Seal Kit

When selecting a seal kit, several factors should be considered

1. Material Compatibility Ensure that the seal materials are compatible with the fluids used in the system to prevent deterioration over time. 2. Operating Conditions Assess the temperature and pressure conditions the seals will be exposed to, as this will influence the selection of materials.

3. Size and Fit Proper dimensions are essential for effective sealing. Always refer to the specifications of the cylinder.

4. Manufacturer Recommendations It's best to use seal kits recommended by the cylinder manufacturer to ensure optimal performance.

In conclusion, seal kit cylinders play a pivotal role in the functionality and reliability of hydraulic and pneumatic systems. By understanding their components, applications, and the importance of high-quality seal kits, operators can significantly enhance the performance and longevity of their machinery. Investing in the right seal kits not only prevents costly downtime but also contributes to a safer and more efficient operational environment. As industries continue to evolve, the need for reliable seal kits will remain a fundamental aspect of engineering and machinery maintenance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories