Dec . 05, 2024 05:24 Back to list

seal hydraulic pump

Understanding Seal Hydraulic Pumps Functionality and Applications

Hydraulic pumps are fundamental components in various industrial and mechanical systems, playing a pivotal role in transferring energy through fluid movement. Among the numerous types of hydraulic pumps, seal hydraulic pumps stand out for their specific design and functionality, offering unique advantages in both performance and reliability.

What are Seal Hydraulic Pumps?

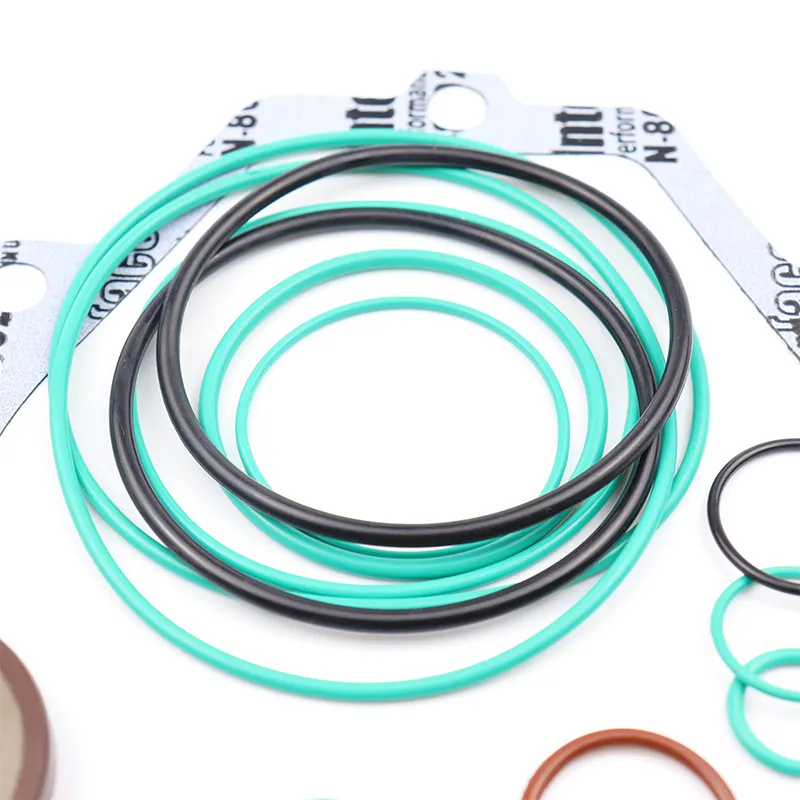

Seal hydraulic pumps utilize a system of seals to ensure the integrity and efficiency of hydraulic fluid transfer. In essence, these pumps convert mechanical energy into hydraulic energy by pressurizing fluids, which are then used to perform work in hydraulic systems. The sealing mechanisms are critical in preventing fluid leakage, which can lead to efficiency losses, environmental hazards, and increased maintenance costs.

The design of seal hydraulic pumps often incorporates a combination of dynamic seals, static seals, and specialized materials to withstand high pressures and harsh operating conditions. Commonly used sealing materials include rubber, fluorocarbons, and thermoplastics, each chosen based on the specific requirements of temperature, pressure, and compatibility with hydraulic fluids.

How Do Seal Hydraulic Pumps Work?

Seal hydraulic pumps operate on a straightforward principle. As the pump motor powers the pump mechanism, it creates a vacuum that draws hydraulic fluid from the reservoir. This fluid is then forced through a series of chambers or paths, thanks to the mechanical energy provided by the motor.

The effective sealing within the pump not only ensures that the hydraulic fluid does not leak out but also maintains the necessary pressure levels for efficient operation. The pressure generated can be varied depending on the pump design, allowing for flexible applications across different industries.

Applications of Seal Hydraulic Pumps

seal hydraulic pump

Seal hydraulic pumps are utilized in numerous applications across various sectors. One notable use is in construction equipment, where they provide the necessary hydraulic power for excavators, bulldozers, and cranes. These machines rely on the high pressure generated by hydraulic pumps to operate their heavy machinery effectively.

Moreover, seal hydraulic pumps are crucial in manufacturing industries. They can be found in hydraulic presses, molding machines, and assembly lines, facilitating tasks such as material pressing, forming, and assembly. The precision and reliability of seal hydraulic pumps ensure consistent performance, which is vital in production environments where downtime can be costly.

In the automotive industry, these pumps are integral to the operation of hydraulic braking systems, power steering, and convertible top mechanisms. Their efficient design contributes to the overall safety and functionality of vehicles, highlighting the importance of reliable sealing technology.

Advantages and Challenges

One of the primary advantages of seal hydraulic pumps is their ability to maintain high operational pressures while minimizing fluid leakage. This efficiency translates into lower operational costs and reduced environmental impact. Additionally, the robust design of these pumps enhances their durability and lifespan, making them an economical choice for many applications.

However, challenges exist, primarily related to seal failure, which can lead to leaks and reduced performance. Regular maintenance and monitoring are essential to identify potential issues before they escalate. Advances in sealing technologies and materials continue to mitigate these challenges, ensuring that seal hydraulic pumps remain a reliable solution in demanding environments.

Conclusion

In summary, seal hydraulic pumps are indispensable in modern industry. Their ability to efficiently transfer hydraulic energy while minimizing leakage makes them essential components in a wide variety of applications. As technology continues to advance, so too will the designs and functionalities of these pumps, further enhancing their role in powering the machinery and processes that drive our economies. Understanding the functionality and applications of seal hydraulic pumps not only highlights their significance but also underscores the importance of ongoing innovation in hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories