Sep . 10, 2024 04:08 Back to list

seal kit hydraulic pump

Understanding the Seal Kit for Hydraulic Pumps

Hydraulic pumps are essential components in various industrial applications, serving as the heart of hydraulic systems. They convert mechanical energy into hydraulic energy, allowing machines to perform tasks such as lifting, pressing, and moving heavy loads. However, one crucial aspect often overlooked in the maintenance and operation of hydraulic pumps is the seal kit. This article will explore the importance, components, and maintenance practices related to seal kits for hydraulic pumps.

Importance of Seal Kits

Seal kits play a vital role in ensuring the efficient and reliable operation of hydraulic pumps. Their primary function is to prevent hydraulic fluid leakage, which can lead to significant loss of efficiency and damage to the pump. A well-functioning seal kit maintains the internal pressure of the hydraulic system, ensuring that the pump operates at optimal performance levels. Furthermore, effective sealing helps to protect the hydraulic fluid from contamination, which could adversely affect the entire hydraulic system's operation.

Components of a Seal Kit

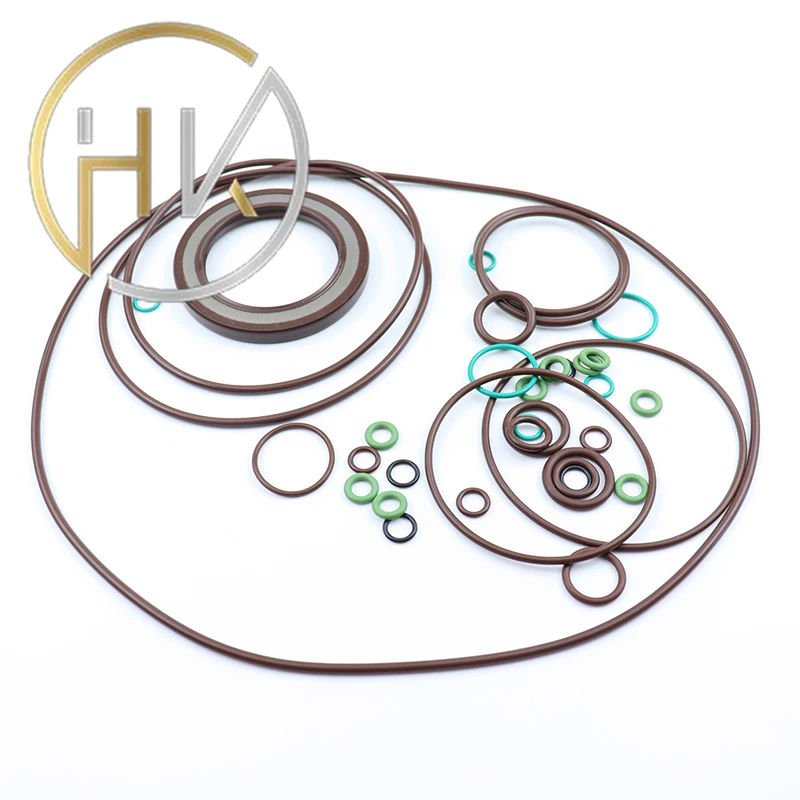

A typical seal kit for hydraulic pumps consists of various components

1. O-Rings These are circular rubber rings that provide a tight seal between two surfaces, preventing fluid leakage. O-rings are often made from materials resistant to high pressure and temperature, ensuring durability.

2. Back-up Rings Designed to support O-rings, back-up rings prevent extrusion in high-pressure applications. They help reduce wear and extend the lifespan of the seal.

3. Guides These components help align the seals and maintain stability during operation. They are typically made from materials that can withstand harsh conditions.

4. Cylinders and Rod Seals These seals are specifically designed for the rod and cylinder areas of a hydraulic pump. They ensure a tight fit around moving parts and prevent any fluid from leaking out.

seal kit hydraulic pump

Maintenance Practices

To ensure the longevity and effectiveness of a seal kit, regular maintenance is essential. Here are some best practices

1. Regular Inspections Routine checks for signs of wear, damage, or degradation in seals can help in early detection of potential problems. If leaks are observed, it is crucial to address them immediately.

2. Fluid Quality Always ensure that the hydraulic fluid used is clean and meets the manufacturer’s specifications. Contaminated fluids can degrade seals faster.

3. Installation Proper installation of seal kits is vital. Misalignment or improper fitting can lead to premature failure. Following manufacturer guidelines during installation can help mitigate these risks.

4. Environmental Considerations Protecting hydraulic pumps from extreme temperatures and harsh environmental conditions can prolong the life of seal kits. Consider using protective covers when necessary.

5. Replacement Seal kits have a finite lifespan. Depending on usage, they may need replacement at regular intervals. Following maintenance schedules as recommended by the hydraulic pump manufacturer is important.

Conclusion

The significance of seal kits in hydraulic pumps cannot be overstated. They ensure efficient operation, prevent fluid leaks, and protect internal components from contamination. Understanding the components and implementing proper maintenance practices will help prolong the lifespan of hydraulic pumps, ultimately saving time and resources in industrial operations. By investing in quality seal kits and adhering to maintenance guidelines, operators can enhance the reliability and performance of their hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories