Feb . 12, 2025 19:46 Back to list

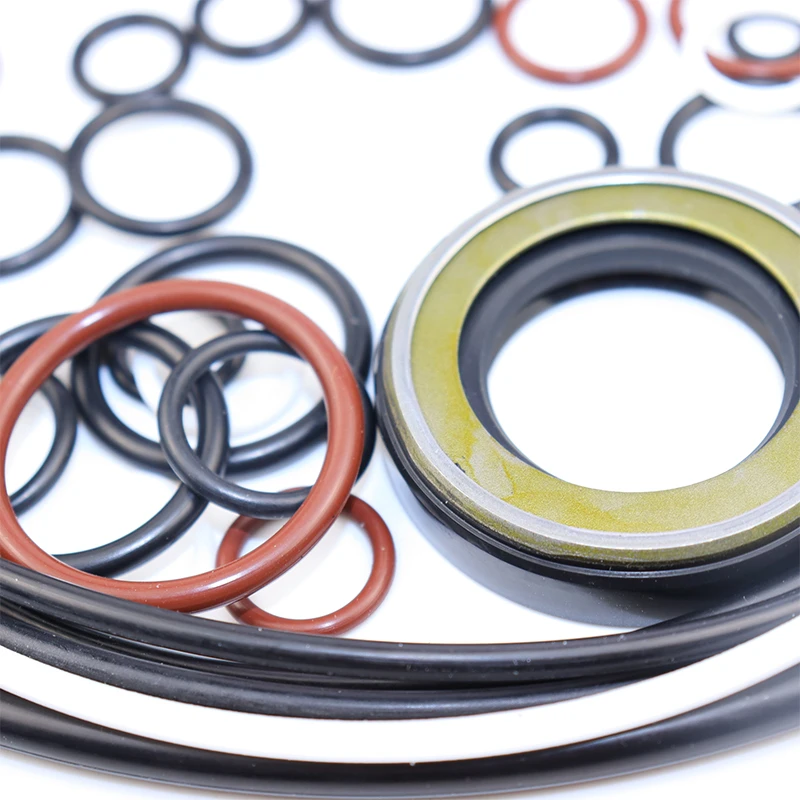

rubber seal kit

In addition to hands-on experience and expertise, the authoritativeness of rubber seal kits can be assessed through industry certifications and compliance with international standards. Kits that adhere to standards set by organizations such as ISO, ASTM, and DIN underscore their credibility and high quality. These standards not only assure the end-user of the kits' reliability but also indicate that the products have been rigorously tested for durability, strength, and safety. An authoritative seal kit is one that a professional can trust to perform consistently under pressure without failure. Trustworthiness is a term that resonates deeply with both manufacturers and end-users of rubber seal kits. Trust is built through rigorous manufacturing processes, consistent product quality, and excellent customer support. Manufacturers who offer comprehensive warranties and transparent return policies instill confidence in buyers, ensuring that they can rely on the product to meet or exceed their expectations. Furthermore, many savvy companies now incorporate real-time monitoring and feedback systems to continually assess and improve the performance of their rubber seals in the field, serving to enhance product trustworthiness. In conclusion, the multifaceted benefits of rubber seal kits can hardly be overstated. Drawing from extensive experience, it is clear these products are indispensable across a wide range of applications due to their innate qualities of durability, adaptability, and performance under pressure. Expertise in selecting the right material for the specific application not only amplifies efficiency but also paves the way for innovative applications that extend beyond traditional uses. With a clear understanding of the importance of adhering to established international standards and maintaining transparency, rubber seal kits stand as a testament to their critical role in advancing industrial capabilities and safeguarding systems worldwide.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories