Nov . 17, 2024 22:53 Back to list

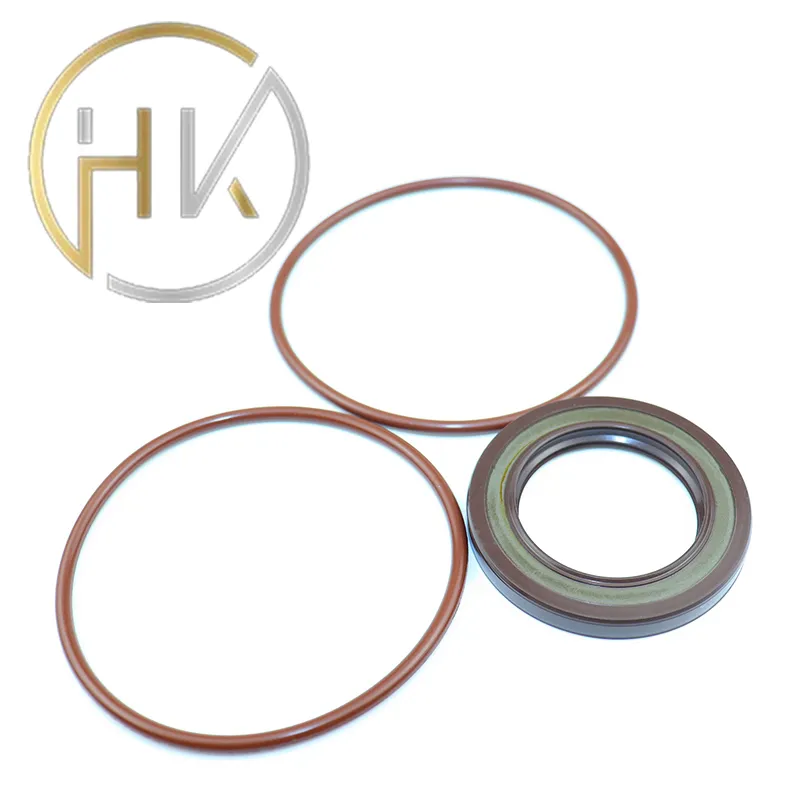

rubber seal kit

The Importance of Rubber Seal Kits in Modern Industries

In today’s industrial landscape, the role of rubber seal kits cannot be overstated. These essential components play a critical role in ensuring the longevity and effectiveness of various machinery and equipment. Whether in automotive applications, machinery manufacturing, or household appliances, rubber seal kits are fundamental in preventing leaks, reducing wear, and maintaining optimal functioning.

1. Understanding Rubber Seal Kits

Rubber seal kits consist of various rubber seals, gaskets, and O-rings designed to function as sealing solutions for diverse applications. Made from durable materials such as nitrile, silicone, and neoprene, these seals are engineered to withstand extreme conditions, including high temperatures, pressures, and exposure to chemicals. The versatility of rubber makes it an ideal choice for these applications as it provides excellent resistance to corrosion and physical degradation.

2. Applications Across Industries

The application of rubber seal kits spans multiple industries. In the automotive sector, they are critical in preventing oil and coolant leaks, ensuring that engines operate efficiently. By maintaining proper functioning of components like pumps, radiators, and transmission systems, seal kits help prolong the lifespan of vehicles. In machinery manufacturing, rubber seals are essential in hydraulic systems, where they help maintain pressure and fluid integrity.

Beyond automotive and industrial machinery, rubber seal kits are also essential in the aerospace industry, where the integrity of sealing components can directly affect safety

. They are used in various aircraft systems to prevent fuel leaks and maintain cabin pressure, underscoring the importance of reliability in high-stakes environments.3. Key Features and Benefits

rubber seal kit

One of the notable benefits of rubber seal kits is their ability to provide a tight, leak-proof seal. This characteristic is vital in applications where even minor leaks can lead to significant failures or safety hazards. Additionally, rubber seals can absorb vibrations and compensate for misalignments, which enhances the overall performance of the machinery.

Another key feature is the ease of installation. Rubber seal kits come in pre-packaged sets, often tailored to specific equipment or machinery, making it more straightforward for technicians to replace old or worn-out seals without extensive downtime. This convenience contributes to increased operational efficiency and reduced maintenance costs.

4. Maintenance and Care

While rubber seal kits are designed for durability, regular inspection and maintenance are crucial for optimal performance. Environmental factors such as temperature fluctuations, exposure to UV rays, and chemical contact can affect the integrity of rubber seals over time. Schedule regular checks to identify signs of wear, discoloration, or brittleness, and replace seals as needed to maintain proper functioning.

Proper installation is equally important. Ensuring that seals are fitted correctly can prevent premature failure and leakage. Following manufacturer guidelines during installation and maintenance can significantly impact the performance and lifespan of rubber seal kits.

5. Conclusion

In conclusion, rubber seal kits are indispensable components in various industries, serving as the first line of defense against leaks and inefficiencies. Their versatile applications, impressive durability, and ease of use make them a vital aspect of maintaining operational efficiency in machinery and equipment. As industries continue to evolve, the development and innovation surrounding rubber seal technology will undoubtedly enhance performance and reliability in numerous applications. Investing in high-quality rubber seal kits and ensuring proper maintenance can lead to substantial long-term savings and improved safety in industrial operations. Thus, the importance of these small yet mighty components should not be underestimated in the quest for efficiency and reliability in modern industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories