Nov . 04, 2024 14:25 Back to list

Rubber Seal Kits for Enhanced Performance and Durability in Various Applications

The Importance of a Rubber Seal Kit Protecting Efficiency and Longevity

In various industries, the integrity of machinery and equipment is crucial for operational efficiency and longevity. One often overlooked component that plays a significant role in maintaining this integrity is the rubber seal kit. These kits provide critical sealing solutions that prevent contamination, leakage, and wear, making them indispensable in numerous applications.

What is a Rubber Seal Kit?

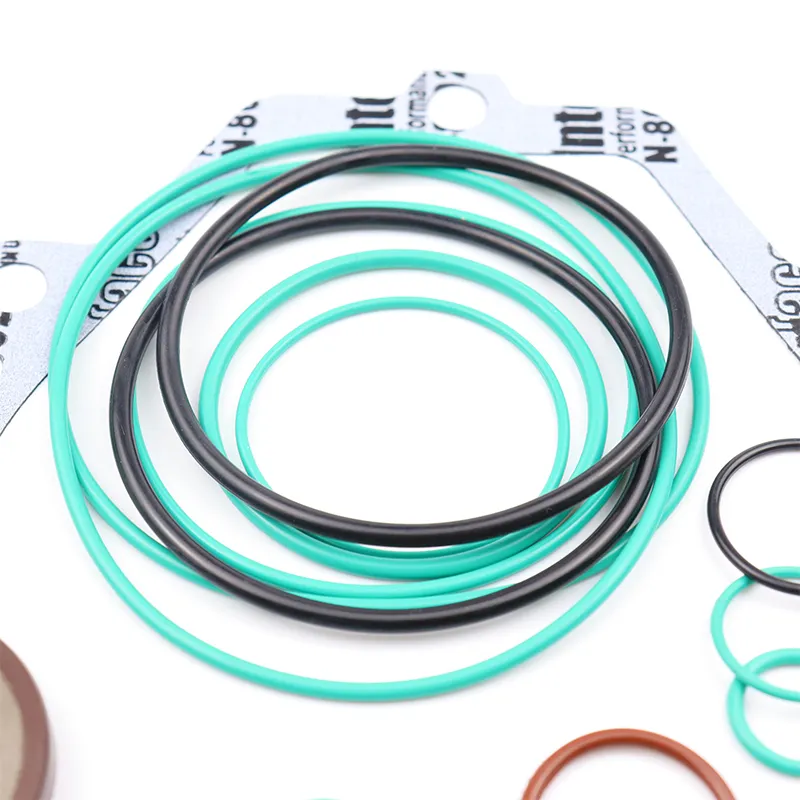

A rubber seal kit typically includes a variety of rubber seals, O-rings, and gaskets specifically designed to fit certain machinery or equipment. These components are formulated from synthetic rubber materials, which offer superior resistance to extreme temperatures, chemicals, oils, and moisture. The primary goal of a rubber seal kit is to ensure that joints and connections remain airtight and watertight, thereby reducing the risk of operational failures caused by leaking fluids or air.

Applications of Rubber Seal Kits

Rubber seal kits find utility in numerous fields, including automotive, aerospace, manufacturing, and construction. For instance, in the automotive industry, they are used in engines, transmissions, and hydraulic systems to secure fluid containment and prevent unwanted leaks. In aeronautics, these seals ensure the integrity of fuel systems and cabin pressurization, crucial for safe flight operations.

In manufacturing, rubber seal kits protect machinery operating under high pressures or temperatures. They help ensure that the valuable lubricants and coolants remain within the system, thereby enhancing performance and preventing wear and tear. In construction, these kits are often utilized in heavy equipment such as excavators and bulldozers, where reliable sealing is necessary to protect hydraulic systems from contamination by dirt and debris.

Benefits of Using Rubber Seal Kits

1. Preventing Leaks The primary function of a rubber seal kit is to provide an effective barrier against leaks. This not only preserves the valuable fluids used in machinery but also helps maintain environmental compliance by preventing spills and potential hazards.

rubber seal kit

2. Enhancing Performance Seals that are properly installed and maintained help machinery run more efficiently. By preventing air or fluid leaks, the system can operate at optimal levels, ensuring better overall performance and productivity.

3. Extending Equipment Life Regular use of rubber seal kits can significantly extend the lifespan of equipment. By preventing contamination and maintaining proper lubrication, these seals help reduce wear on internal components, ultimately leading to lower maintenance costs and diminished risk of costly downtime.

4. Versatility Rubber seal kits can be customized for a wide range of applications, materials, and sizes. This adaptability makes them suitable for nearly any industry, allowing businesses to find the right solution for their specific sealing needs.

5. Cost-Effective Solution Investing in quality rubber seal kits can save money in the long run. While the upfront cost may seem notable, the benefits gained from reduced leaks, less maintenance, and prolonged equipment life more than justify the investment.

Choosing the Right Rubber Seal Kit

When selecting a rubber seal kit, it is essential to consider several factors. These include the specific application, the types of fluids the seals will encounter, and the environmental conditions (such as temperature and pressure) they must withstand. Consulting with a specialist or supplier who understands your unique requirements can help you choose the best kit for your needs.

Conclusion

In summary, rubber seal kits are vital components that offer robust solutions to overcome sealing challenges in various applications. Their ability to prevent leaks, enhance performance, extend equipment life, and provide versatility makes them an integral part of industrial and commercial operations. As technology continues to advance, the materials and designs used in these kits will also evolve, further improving their efficiency and reliability. Incorporating high-quality rubber seal kits into regular maintenance routines is a smart investment, ensuring that machinery runs smoothly and effectively for many years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories