Nov . 17, 2024 02:46 Back to list

rubber hub seal

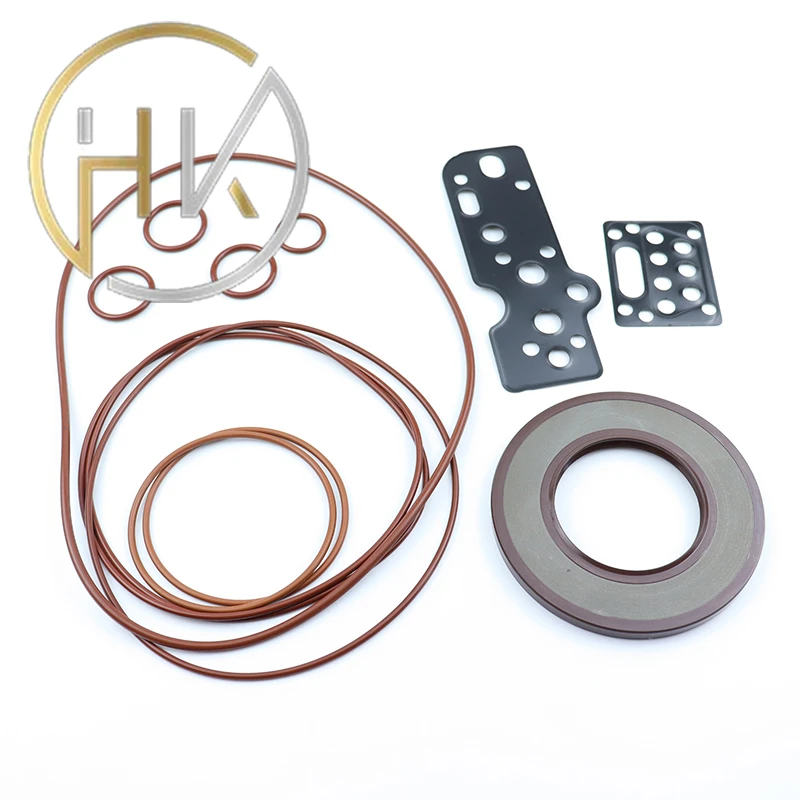

Understanding Rubber Hub Seals Their Importance and Applications

Rubber hub seals play a crucial role in various machinery and vehicle components, ensuring efficient operation and longevity. As an essential sealing solution, they serve to protect critical areas from contamination, retain lubricants, and maintain pressure. In this article, we will explore the composition, design, applications, and significance of rubber hub seals in different industries.

Composition and Design

Rubber hub seals are typically made from elastomeric materials that offer flexibility, durability, and resistance to wear and tear. Common materials include NBR (nitrile butadiene rubber), FKM (fluoroelastomer), and silicone, each chosen for their specific properties suited to different environments and applications. The design of these seals often includes a lip that fits snugly against a rotating element, such as a hub or shaft, creating a barrier that prevents leaks and ingress of dirt and moisture.

Functionality

The primary function of rubber hub seals is to provide a secure sealing solution that keeps lubricants contained within the machinery while preventing external contaminants from entering

. This is particularly important in applications involving bearings, such as in vehicles and industrial equipment, where the lubrication is critical for preventing overheating and wear.In addition to fluid retention, rubber hub seals also help maintain pressure within systems, which is vital for operational efficiency. In hydraulic equipment, for instance, maintaining proper pressure is essential for optimal performance and safety; a compromised seal can lead to significant operational failures.

rubber hub seal

Applications

Rubber hub seals are employed in a variety of sectors, reflecting their versatility. In the automotive industry, these seals are commonly found in wheel hubs, differentials, and transmission systems. They help prevent the ingress of dirt and moisture, which can lead to corrosion and premature wear. Moreover, by retaining lubricants, they enhance the longevity of components, saving time and costs associated with repairs and replacements.

In industrial machinery, rubber hub seals are essential for maintaining the integrity of bearings and shafts within machines that are exposed to harsh conditions. Industries such as manufacturing, construction, and agriculture rely on these seals to ensure the reliable operation of equipment like conveyor systems, forklifts, and tractors.

Marine applications also benefit significantly from rubber hub seals. Boats and ships are often subjected to water exposure and various environmental conditions that can challenge the durability of mechanical components. Properly functioning rubber hub seals help in protecting against water ingress, ensuring the safe and efficient operation of marine machinery.

Conclusion

In summary, rubber hub seals are a vital component in the operation of various machinery and vehicles across multiple industries. Their ability to seal, protect, and retain lubricants ensures optimal performance and longevity of critical components. As industries continue to evolve, the demand for robust sealing solutions like rubber hub seals will remain integral to achieving efficiency and reliability in operations. Investing in high-quality rubber hub seals not only safeguards equipment from damage but also enhances overall productivity, demonstrating their significant contribution to modern mechanical engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories