Dec . 11, 2024 10:45 Back to list

Understanding Rotary Shaft Oil Seals for Enhanced Machinery Performance and Longevity

Understanding Rotary Shaft Oil Seals

Rotary shaft oil seals are crucial components in various mechanical systems that involve rotating shafts. They play a pivotal role in preventing the leakage of lubricants from rotating machinery and protecting internal components from contaminants. This article delves into the importance, function, construction, and maintenance of rotary shaft oil seals.

Purpose and Function

The primary function of rotary shaft oil seals is to retain lubricants while preventing contaminants such as dust, dirt, and moisture from entering the machinery. In many applications, such as engines, gearboxes, and pumps, oil seals help maintain the internal pressure and performance of the system. They ensure that the lubricant remains in contact with the moving parts, which reduces friction, wear, and heat generation.

Additionally, oil seals contribute to the overall efficiency of the equipment. A well-functioning oil seal can improve the longevity and reliability of machinery by minimizing the risk of fluid leaks, which can lead to operational failures or environmental hazards.

Construction

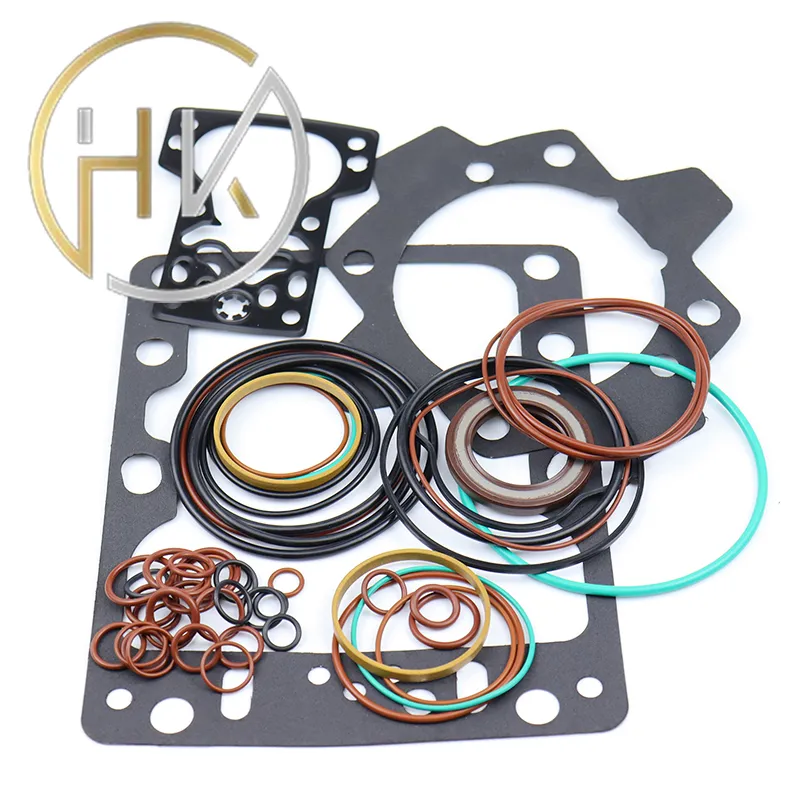

Rotary shaft oil seals typically consist of several key components. The main body is usually made from durable materials such as rubber, elastomers, or thermoplastics. These materials are selected for their resistance to wear, temperature variations, and chemical exposure. The sealing lip, which comes in contact with the rotating shaft, is designed to create a tight seal that prevents lubricant leakage.

Some oil seals also include metal reinforcement to enhance strength and durability. The design may incorporate various features like garter springs to maintain lip contact with the shaft, ensuring optimal sealing performance even under challenging operating conditions.

Types of Rotary Shaft Oil Seals

There are several types of rotary shaft oil seals, each designed to meet specific requirements

rotary shaft oil seals

1. Single Lip Seals These seals have one sealing lip and are commonly used in standard applications where moderate sealing is required.

2. Double Lip Seals Featuring two sealing lips, these seals provide enhanced protection against contaminants and are ideal for applications exposed to more demanding environments.

3. Spring-Loaded Seals These incorporate a spring to maintain pressure against the rotating shaft, ensuring a tighter seal and reducing the likelihood of leaks.

4. PTFE Seals Made from Polytetrafluoroethylene, PTFE seals are highly resistant to heat and chemical exposure, making them suitable for extreme environments.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and effectiveness of rotary shaft oil seals. Operators should routinely inspect seals for signs of wear, deformation, or damage. A leaking seal can indicate that replacement is necessary, as even minor leaks can lead to significant issues over time.

When replacing oil seals, it is crucial to choose the right type and size for the application. Proper installation is also critical—incorrectly installed seals may lead to premature failure or leakage. Subsequently, during operation, monitoring for any unusual noises or performance issues can help identify seal-related problems early on.

Conclusion

Rotary shaft oil seals are integral to the functionality and efficiency of mechanical systems involving rotating shafts. By effectively containing lubricants and protecting machinery from contaminants, these seals play a vital role in enhancing the performance and lifespan of equipment. Understanding their construction, types, and maintenance requirements can help operators ensure the reliability and efficiency of their mechanical systems. In both industrial and automotive applications, investing in high-quality rotary shaft oil seals can lead to improved performance, reduced downtime, and ultimately, cost savings in repairs and replacements.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories