Oct . 31, 2024 02:11 Back to list

rotary shaft oil seals

Understanding Rotary Shaft Oil Seals Importance and Applications

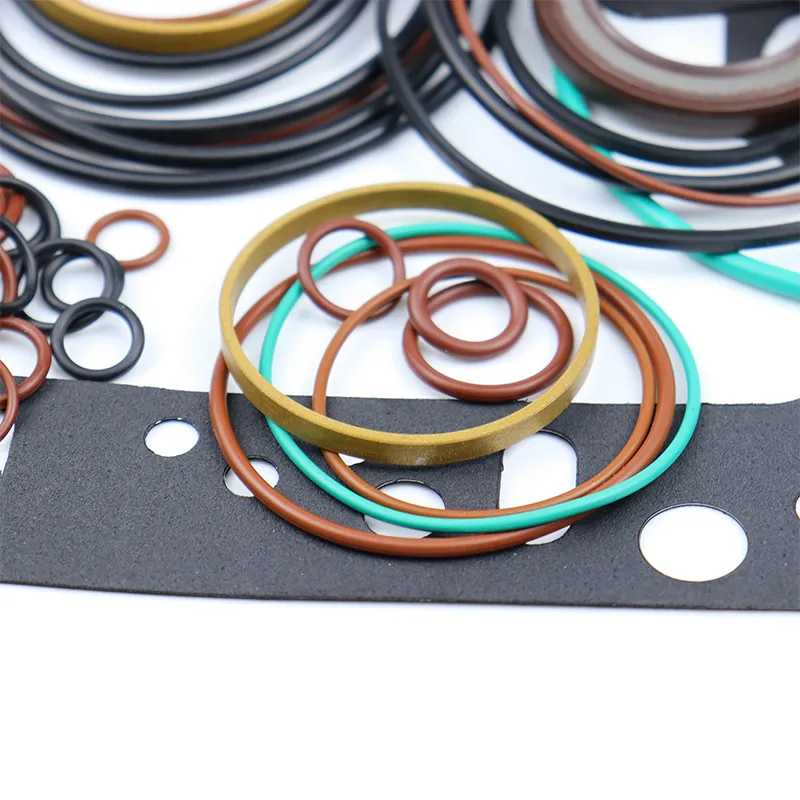

Rotary shaft oil seals are critical components in various mechanical systems, primarily designed to prevent leakage of lubricants and protect the internal components from contamination. These seals play a vital role in maintaining the efficiency and longevity of machinery by ensuring that oil and other fluids remain where they are intended, and contaminants stay out.

What Are Rotary Shaft Oil Seals?

Rotary shaft oil seals, commonly referred to as oil seals, are circular sealing devices installed in machinery where a rotating shaft meets a stationary housing. Typically made from materials like rubber, silicone, or fluorocarbon, these seals form a barrier that keeps oil and grease in while preventing dirt, dust, and moisture from entering the system. Their design usually features a flexible lip that presses against the shaft, creating a tight seal that is crucial for reliable operation.

Key Functions of Rotary Shaft Oil Seals

1. Preventing Leakage One of the primary functions of rotary shaft oil seals is to prevent the escape of lubricants. In many machines, especially engines and gearboxes, maintaining the correct oil level is essential for proper function. Even minor leaks can lead to significant mechanical failures over time.

2. Protection Against Contaminants By sealing off the internal components, oil seals help prevent the ingress of contaminants such as dirt, debris, and moisture. This is especially crucial in harsh operating environments, where external elements can significantly degrade the performance and lifespan of the machinery.

3. Pressure Management Many rotary seal designs can withstand varying pressure levels, allowing for efficient performance in both vacuum and pressurized environments. This adaptability is essential in applications like automotive engines, where pressure can fluctuate.

Types of Rotary Shaft Oil Seals

rotary shaft oil seals

Several types of rotary shaft oil seals are available, designed for specific applications. Common types include

- Single-lip seals Typically used in applications where there is low pressure and minimal contamination risk. - Double-lip seals Designed for higher pressure applications, these seals provide an additional line of defense against contamination. - Spring-loaded seals Featuring a spring mechanism that maintains pressure against the shaft, ensuring a tighter seal even with wear over time.

Applications of Rotary Shaft Oil Seals

Rotary shaft oil seals are used in diverse sectors and applications, including

- Automotive Used in engines, transmissions, and differentials to keep lubricants contained and thwart contaminants. - Industrial Machinery Essential for hydraulic systems, pumps, and compressors where keeping fluids in and contaminants out is crucial for operational efficiency. - Aerospace In aviation applications, oil seals protect sensitive engine components from wear and ensure optimal performance.

- Home Appliances Found in washing machines, vacuum cleaners, and other devices where fluid leakage could lead to malfunction.

Conclusion

In summary, rotary shaft oil seals are indispensable components that ensure the effective operation of numerous mechanical systems. By preventing leaks and protecting against contaminants, they help maintain the efficiency, performance, and longevity of machinery across a wide range of applications. Understanding the functionality and types of these seals is critical for engineers and technicians in designing and maintaining reliable equipment. As technology advances, the materials and designs of rotary shaft oil seals are likely to evolve, further enhancing their performance in demanding environments.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories