Dec . 04, 2024 16:11 Back to list

ross hydraulic motor seal kit

Understanding Ross Hydraulic Motor Seal Kits

Hydraulic motors play an essential role in various industrial applications, providing efficient power transmission and smooth operations. A crucial component that contributes to their optimal performance is the seal kit. Among the various manufacturers, Ross hydraulic motors stand out for their reliability and engineering excellence. This article will explore the importance of seal kits, particularly the Ross hydraulic motor seal kit, discussing its components, significance, and maintenance tips.

The Role of Seal Kits in Hydraulic Motors

Seal kits are a collection of seals, O-rings, gaskets, and various other sealing components designed to prevent fluid leaks and maintain hydraulic pressure within the motor. In hydraulic motors, improper sealing can lead to inefficiencies, increased wear, and ultimately, malfunction. The primary functions of a seal kit include

1. Leak Prevention Seals prevent hydraulic fluid from escaping, which is essential for maintaining system pressure. 2. Contaminant Exclusion They protect the internal mechanisms of the motor from dirt, dust, and other contaminants that could cause wear or damage. 3. Pressure Maintenance Proper seals ensure that the hydraulic system maintains the necessary pressure for effective operation. 4. Enhancing Efficiency By preventing fluid leaks, seal kits help maintain the efficiency of hydraulic systems, which translates to cost savings and enhanced productivity.

Components of Ross Hydraulic Motor Seal Kits

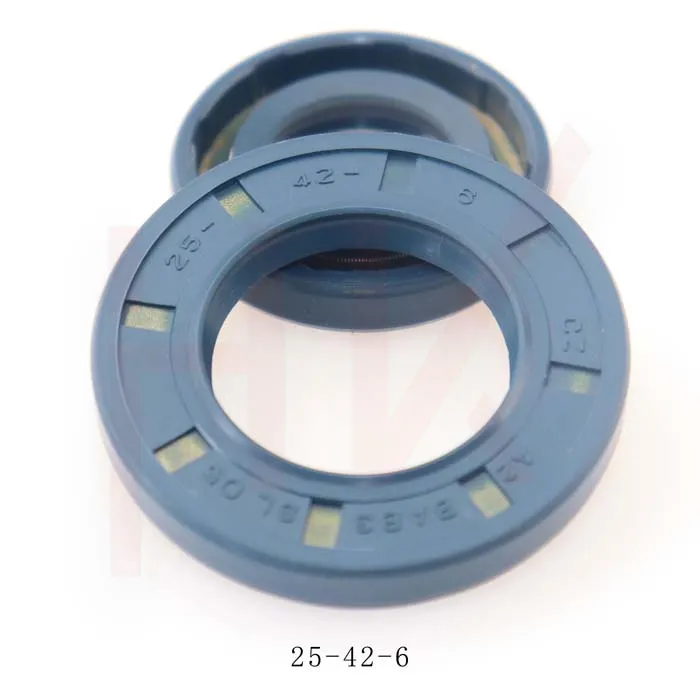

A typical Ross hydraulic motor seal kit includes various components specifically designed for different models of Ross hydraulic motors. These may include

- O-Rings Essential for creating airtight seals around components, preventing fluid leakage effectively. - Gaskets Used between mating surfaces to prevent leaks and maintain pressure. - Backup Rings Often paired with O-rings, they provide extra support to withstand high-pressure environments. - Wipers/Excluders Designed to keep contaminants out while allowing the piston to move smoothly. - Wear Rings Help reduce friction between moving parts, contributing to the longevity of the hydraulic motor.

ross hydraulic motor seal kit

Importance of Using the Correct Seal Kit

Using the appropriate seal kit, such as the Ross hydraulic motor seal kit, is vital for the successful operation of hydraulic systems. Different motors have distinct designs and operational requirements, thus necessitating specific sealing solutions. Using a mismatched or inferior seal kit can lead to premature failure of components, increased maintenance costs, and unexpected downtimes.

Maintenance Tips for Hydraulic Motors

Maintaining hydraulic motors is crucial to ensure longevity and performance. Here are some tips for maintaining Ross hydraulic motors and their seal kits

1. Regular Inspections Periodically inspect hydraulic motors for leaks, abnormal noises, or performance issues. 2. Fluid Quality Check Ensure that the hydraulic fluid is clean and at the recommended level. Contaminated or low fluid can cause excessive wear on seals and components. 3. Seal Replacement Follow the manufacturer's recommendations for seal replacement intervals. Even the best seal kits wear out over time due to pressure and operational demands. 4. Monitor Temperature Abnormal operating temperatures can affect the performance and longevity of seals. Ensure that the hydraulic system is working within the specified temperature range. 5. Proper Storage When storing seal kits, ensure they are kept in a clean, dry environment away from direct sunlight and extreme temperatures to prevent degradation.

Conclusion

In the realm of hydraulic motors, seal kits, particularly the Ross hydraulic motor seal kit, play a pivotal role in ensuring reliability and efficiency. Their components are designed to counteract the pressures and challenges faced in hydraulic applications. Regular maintenance and the use of high-quality, specifically designed seal kits not only enhance the performance of hydraulic motors but also prolong their service life. By investing in proper sealing solutions and paying attention to maintenance, operators can achieve optimal performance from their hydraulic systems, minimizing unexpected downtimes and maximizing productivity.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories